Swing Bridge Reverse Engineering Simplified with Geomagic Design X

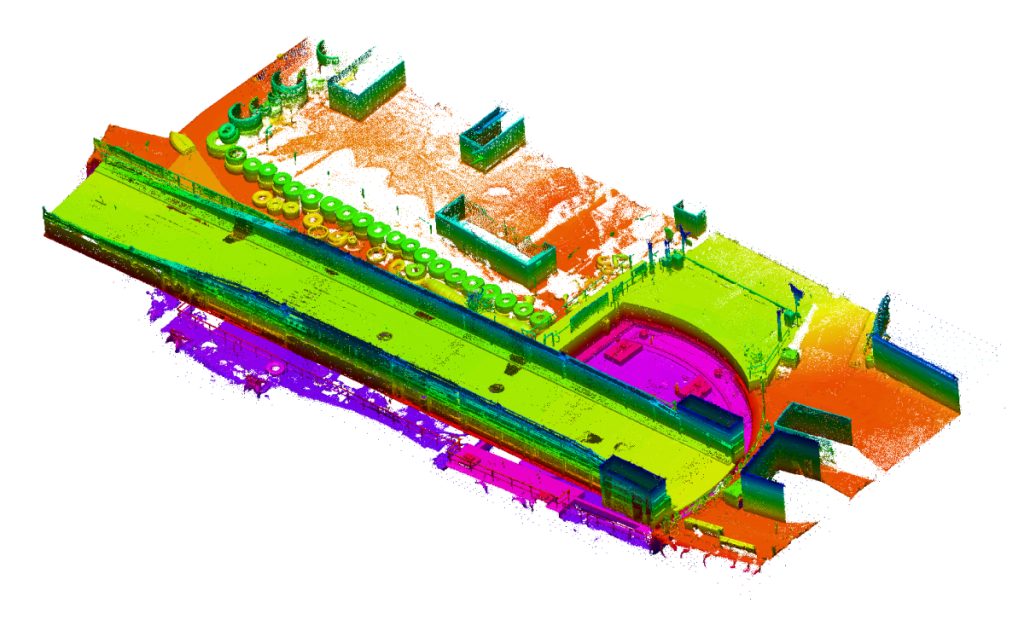

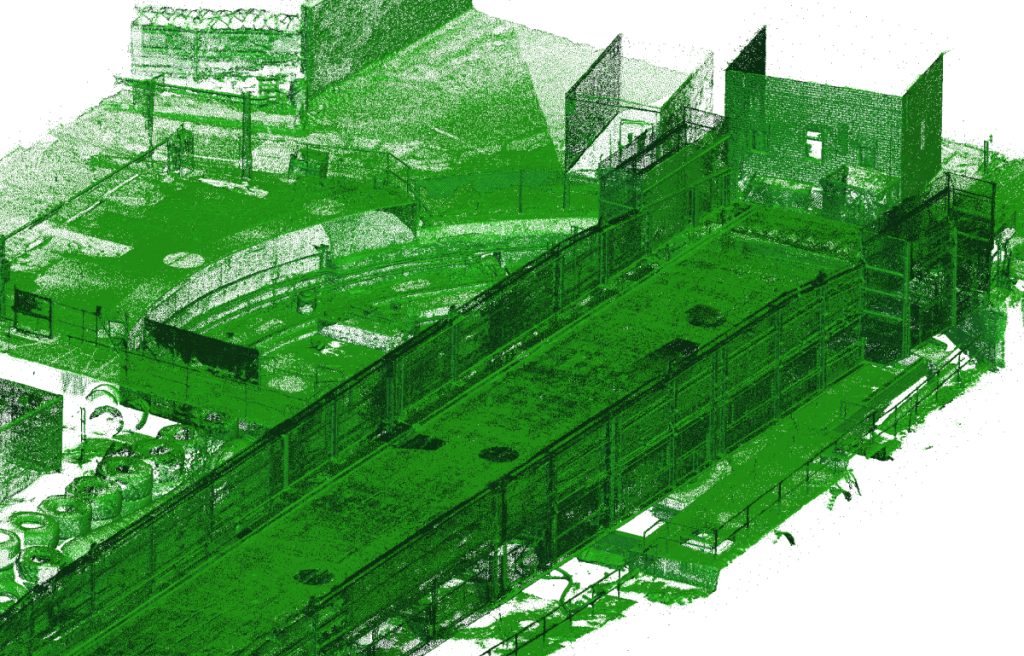

A swing bridge in a coastal dock system was decommissioned after being twisted. A ferry company needed it operational for car parking but faced a dilemma: closing the bridge to test it could jam it if it wasn’t functioning. Unable to test physically, they created a digital twin using a long-range laser scanner and simulated the bridge’s motion if closed.

Scanning a swing bridge

Accuracy of the essence

Modeling and data processing took a few days due to complexity. “Once we modeled the bridge in Design X, we ran the simulations, and saw the bridge was going to collide in a certain position,” Kean explains. “That gave the company the confidence to try it for real.” The simulation predicted a two-to-three-millimeter collision, confirmed in real-life. “We wouldn’t have been able to simulate this correctly without accuracy, both with the scan data and the CAD model. Realistically, Geomagic Design X is the only package able to do that,” Kean says.

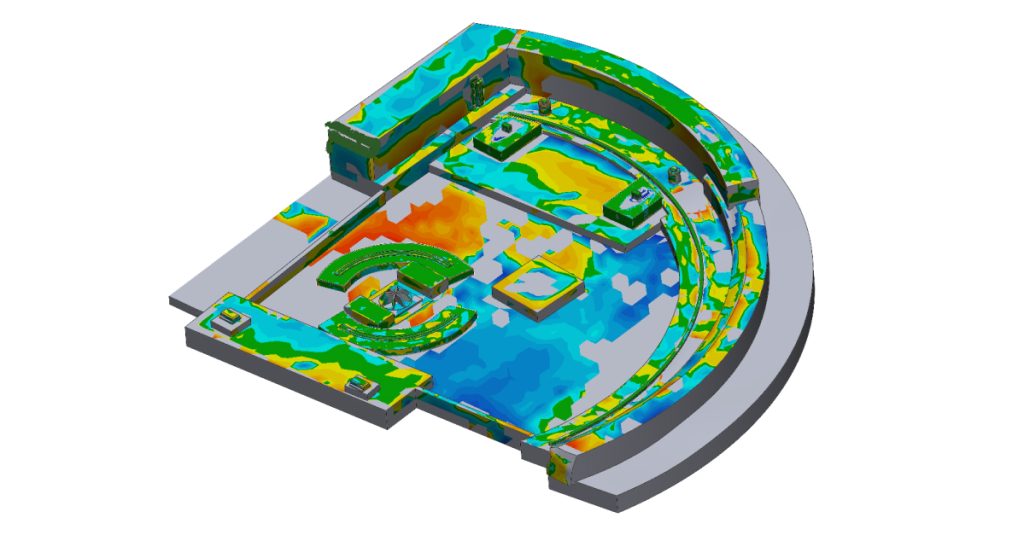

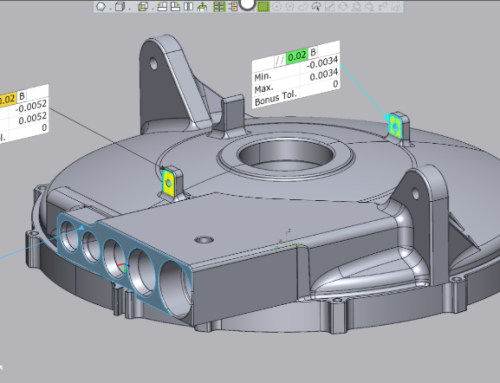

A few features ensured accuracy, like MeshSketch and Deviation Analysis. “Within the sketch we can immediately check the deviation between primitive sketch entities, be it a line, an arc or even a spline, and the data so we can see how accurately we’re drawing,” Kean explains.

3D deviation analysis shows surface deviation using a color map. “Knowing how accurately we’re modeling allows us to go back to the customer and say with confidence what’s going to happen to the bridge. Without that constant feedback that you’re getting from Geomagic Design X it’s very difficult to model well,” he says.

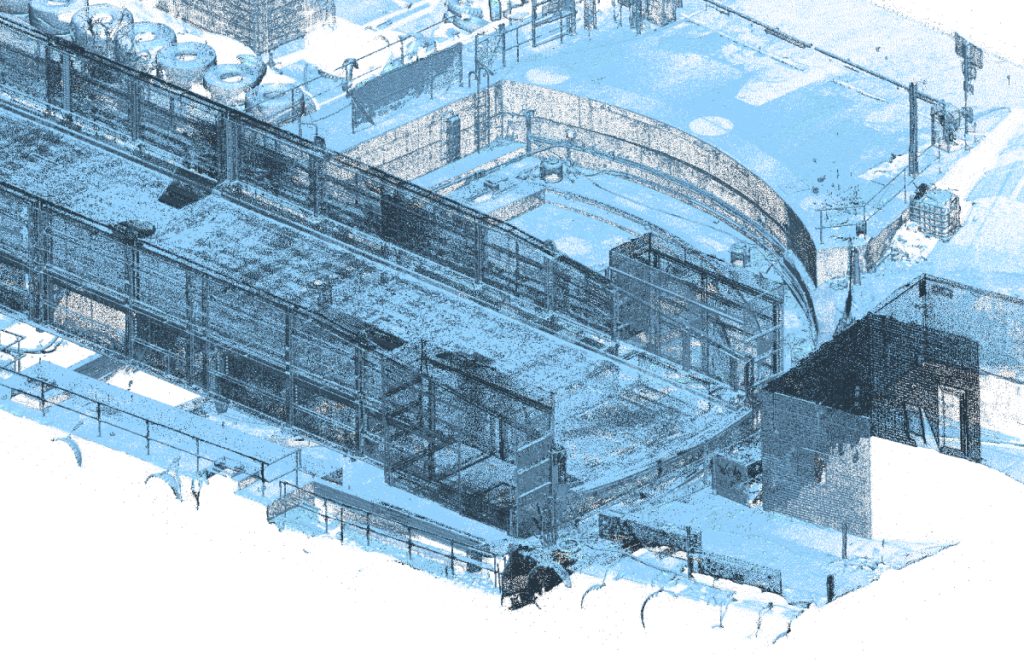

More than traditional CAD

Kean chose Geomagic Design X for its traditional modeling techniques and efficient scan editing. “Most CAD packages these days can handle some mesh format, but they cannot handle anywhere near the range of mesh formats that Design X can.” Geomagic Design X excels with large data sets. “Traditional CAD packages can’t handle that size of data. Initially, we’re probably talking about a few hundred million points and then we would decimate that down. But decimating is another thing you can’t do with traditional CAD packages,” Kean says.

Geomagic Design X allows efficient data handling and decimation. “Traditional CAD software would have locked up at that point,” Kean says. The client was impressed with the clarity and accuracy. “No other reverse engineering package is capable of anywhere near the modeling capability that Design X is,” Kean says.

Leave A Comment