The Benefits of Mastercam Thread Milling

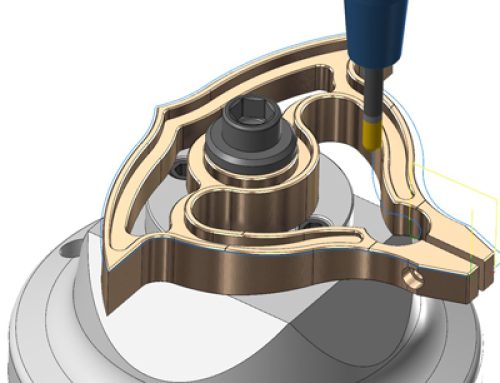

Thread milling is a versatile and efficient method for creating threads in a variety of materials using Mastercam. Here’s a look at the key benefits of using Mastercam for thread milling:

1. Precision and Accuracy

Mastercam’s advanced toolpath algorithms ensure that threads are cut with high precision and accuracy. This is crucial for applications where tight tolerances are required, such as in aerospace and medical device manufacturing. The software allows for precise control over thread dimensions, ensuring consistent quality.

2. Versatility

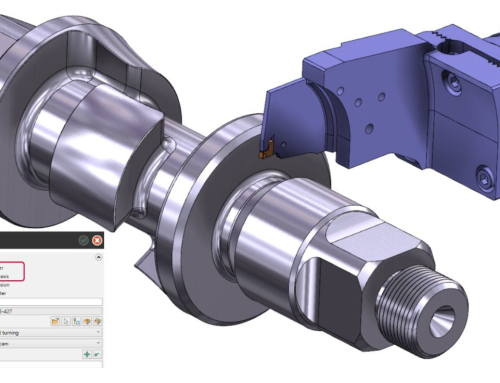

Thread milling with Mastercam is highly versatile. It can be used to create both internal and external threads, and it supports a wide range of thread forms, including metric, UNC, UNF, and custom threads. This versatility makes it suitable for a variety of applications and industries.

3. Tool Life Extension

Thread milling typically results in less wear and tear on tools compared to traditional tapping. Mastercam’s optimized toolpaths reduce cutting forces and heat generation, which can significantly extend the life of your thread mills. This leads to cost savings on tooling and less downtime for tool changes.

4. Reduced Risk of Broken Tools

Unlike tapping, which can easily result in broken taps if the tool encounters an obstruction or if there is a sudden change in material hardness, thread milling is a more forgiving process. Mastercam’s toolpath strategies help to minimize the risk of tool breakage, enhancing overall process reliability.

5. Flexibility in Thread Depth and Diameter

Mastercam allows for easy adjustments to thread depth and diameter, providing greater flexibility in the manufacturing process. This is particularly beneficial when working with parts that have varying thread requirements or when prototyping new designs.

6. Improved Surface Finish

The helical interpolation used in thread milling produces a superior surface finish compared to tapping. Mastercam’s precise control over the cutting process ensures smooth and clean thread surfaces, which can be critical for the performance and longevity of threaded components.

7. Efficient Material Removal

Thread milling is an efficient material removal process. Mastercam’s toolpaths are designed to maximize material removal rates while minimizing cycle times. This efficiency translates to faster production times and increased throughput.

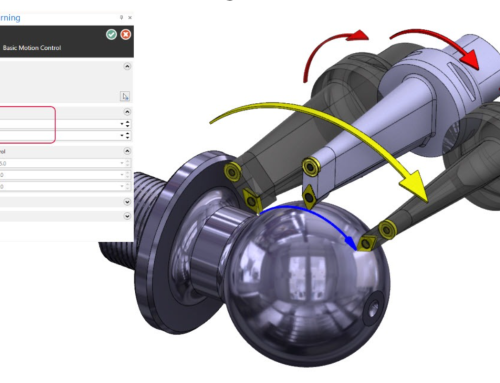

8. Enhanced Programming Capabilities

Mastercam’s user-friendly interface and powerful programming capabilities make it easy to create and modify thread milling toolpaths. The software provides a range of options for customizing toolpaths to meet specific requirements, and its simulation features allow for thorough verification before actual machining.

Conclusion

Mastercam thread milling offers numerous benefits that can enhance the quality, efficiency, and reliability of your threading operations. From precision and versatility to improved tool life and surface finish, Mastercam provides the tools and capabilities needed to achieve superior results. Whether you’re working on high-precision components or looking to optimize your production processes, Mastercam thread milling is a valuable solution.

To find out more about thread milling with Mastercam 2025, contact us today.

Leave A Comment