The First Environmental Evaluation of 3D-Printed Footwear

A team of graduate students at Yale’s Center for Business and the Environment worked with HILOS and with data provided by their supply chain partners – BASF Forward AM and AMT – to examine each piece of their environmental impact. They then benchmarked the results against traditional footwear supply chain emissions to answer the

A team of graduate students at Yale’s Center for Business and the Environment worked with HILOS and with data provided by their supply chain partners – BASF Forward AM and AMT – to examine each piece of their environmental impact. They then benchmarked the results against traditional footwear supply chain emissions to answer the

following questions:

How does 3D-printed footwear compare to legacy shoemaking?

Where does the technology have the potential to deliver the greatest environmental impact?

Where are the greatest opportunities for future improvement, and how do we get there?

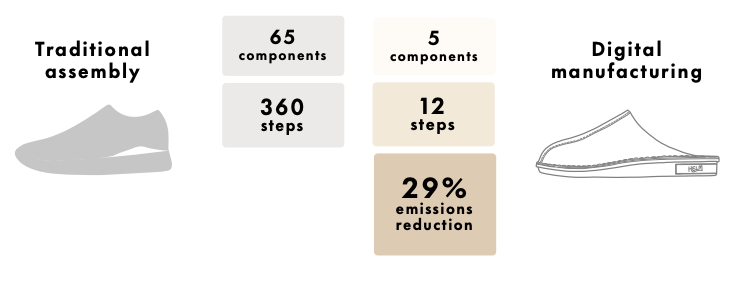

Their mission is to stop waste before it starts, pioneering 3D-printed shoes made on-demand, without inventory or waste. After launching their first line in 2021, they

teamed up with footwear brand HELM to showcase a new collaboration model for the industry. Designed by HELM and made on-demand by HILOS, the Emmett slip-on mule became the focus for this case study.

Leave A Comment