AMT PostPro SFX: Desktop Vapor Smoothing for 3D Printed Parts

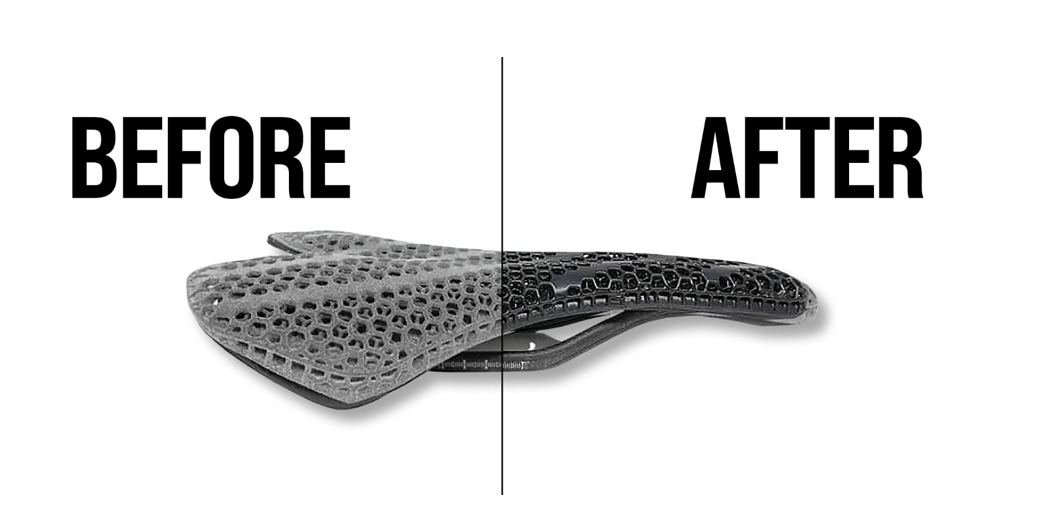

3D printed, unprocessed parts exhibit a rough and porous surface, which limits their use in various applications. To solve this issue, AMT PostPro developed its own patented vapor smoothing process to deliver 3D prints that are more durable with smoother and sealed surfaces. As part of their vapor smoothing product line, AMT has also developed a benchtop machine size. The PostPro SFX brings industrial vapor smoothing to a desktop-scale system.

Why Choose the PostPro SFX for Vapor Smoothing?

Designed for small-batch production, laboratories, and workshops, the SFX system delivers high-quality surface finishes on a range of thermoplastic parts made using SLS, MJF, SAF, HSS and high temperature FDM printing technologies. This vapor smoothing system is ideal for any manufacturer looking to scale their post-processing workflow gradually. The benefits include:

- Smooth and sealed surfaces for end-use 3D printed parts

- Compatible with a range of thermoplastics, including PA11, PA12, TPU, composites, and PEI.

- Supports materials printed with MJF, SLS, high temperature FDM, SAF, and HSS

- Uses our non-hazardous, biodegradable consumable, PostPro Pure

- Delivers repeatable, high-quality results in just under two hours

- It’s plug and play. The process is easy, and no facility modifications are required

How does the PostPro SFX work?

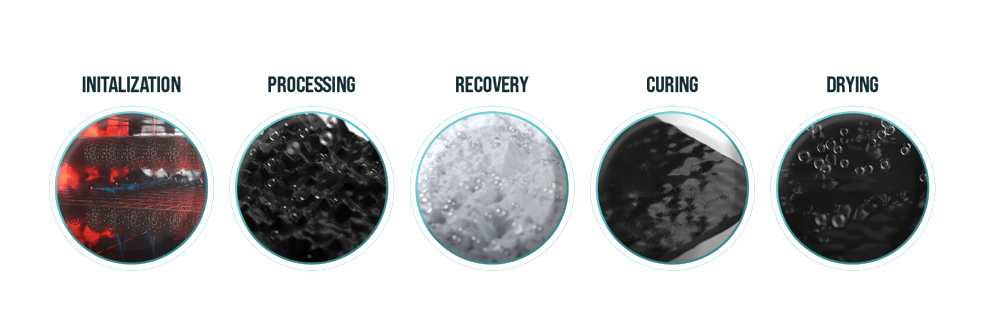

The PostPro SFX uses controlled vapor smoothing to mobilize the outer surface layer of 3D-printed parts. The vaporized consumable reflows the rough surface, eliminating microporosity and thereby creating a uniform surface. The cycle lasts ~ 2 hours and includes the following steps:

- Initialization Phase: While the SFX machine warms up to reach the optimal thermal processing environment, the parts can be prepared for the process and hung on the machine racks.

- Processing Phase: Once the parts have been placed in the chamber and the chamber door has closed, the consumable is vaporized and dispersed throughout the chamber so that it can condense on the parts and initiate smoothing.

- Recovery Phase: The consumable is recovered from the SFX chamber via a drainage system.

- Curing Phase: The parts are now exposed to gentle heat to dry any “wet” surfaces and return the parts into a hardened, useable state

- Drying Phase: Gentle heat is introduced into the chamber ensuring the parts are completely dry and ready for use.

The SFX and FLEX

The SFX system combines applied science and easy-to-use technology into a combined software system called FLEX to make anyone of any experience level an automatic Finishing Level EXpert.

Thanks to its compatibility with our green and non-hazardous consumable PostPro Pure, the PostPro SFX provides users with a sustainable post-processing solution to deliver repeatable and smooth parts within a couple of hours. Processed parts not only achieve high aesthetic standards but also show improved mechanical performance, dyeing uniformity, and ease of painting.

The SFX is the first and only commercially available desktop vapor smoothing unit. AMT has been delivering the industry standard in automated post-processing equipment since its founding in 2017 and is currently the global leader in vapor smoothing technology.

Leave A Comment