Architectural Models

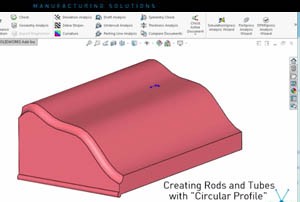

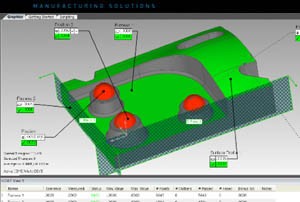

http://cimquesttv.wistia.com/medias/wfgts54ffx?embedType=async&videoFoam=true&videoWidth=640 Through 3D printing, architects can seamlessly convert their digital CAD file into high-quality 3D models. These models can achieve a high level of quality and detail,including full color and complex internal geometry.