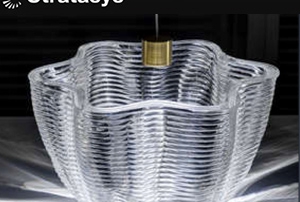

Additively Manufactured Fine Glass

Reposted from http://www.economist.com/ GLASSMAKING began 4,500 years ago, in Mesopotamia. The industry’s first products were trinkets, such as beads and pendants, cast from moulds and carved by hand. But craftsmen quickly worked out how to make more practical stuff, such as jugs, bottles and drinking vessels, by coiling strands of molten glass around a sand or clay core of appropriate shape, which could then be shaken or scraped out after the glass had cooled. Since [...]