From an Engine Port to a Machinable Multi-Axis CNC Toolpath

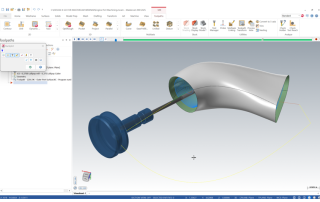

One of our customers was recently faced with the challenge of needing to machine a complex engine port shape without a CAD model, having a circular cross-section on one end, oval on the other and was bent 90 degrees Due to the bend, the port would also need to be machined, from both ends. Below is a cross section of a similar port with a porting cutter positioned to check the depth we could reach, [...]