New UltiMaker Cura 5.8 Beta Enables Better Z Seams and More

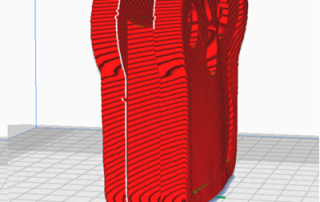

Another Cura release has arrived and in this 5.8 beta release, the focus is on improving Z seams, as well as completing support for the full Method series of printers by introducing a profile for the UltiMaker Method. Z seams look better than ever thanks to new settings New settings have been added that let you tweak how and where the Z seam is placed. The settings are: Z Seam On Vertex Seam Overhang Angle Support Z Seam Away From Model When “User Selected” or “Shortest” is selected as your Z seam location option, the Z seam will follow the selected (or shortest) position exactly. However, when the new “Z Seam On Vertex” option is selected, the Z seam will instead be placed on the nearest vertices (usually a corner). This allows you to hide your Z seam on areas of your model where it will not be so noticeable. You can see this behavior in the following image: Left: Z Seam On Vertex disabled, right: Z Seam On Vertex enabled The new “Seam Overhang Angle” allows you to choose an angle after which seams will not be printed on overhangs (including when “Z Seam On Vertex” is selected). This improves [...]

Improving the Surface Finish for 3D printed parts with the AMT PostPro SFX

Cimquest’s Desktop Vapor Smoothing System the PostPro SFX from AMT is now operational. Which means that our application engineers are now capable of running benchmarks for customers who want to see how this technology and process will work for them. What is “vapor smoothing”? A solvent is vaporized in a chamber under carefully controlled conditions. The vapor evenly condenses on the external surfaces (and internal if there is line-of-sight) of 3D printed thermoplastic parts. This reduces or eliminates the layer lines created by 3D printing by softening the surfaces and filling-in the gaps between the peaks and valleys; it also seals the surfaces. The resultant benefits of vapor smoothing are: Reduction of surface roughness – as much as 420% (comparable to injection molding). Improvement of mechanical properties – up to 3X (improvements in elongation at break and tensile strength). Seals the surfaces – great for applications that require water tightness or sterilization. Who is AMT? (Additive Manufacturing Technologies) AMT has been producing industrial post processing equipment for nearly a decade. Their vapor smoothing technology is used to enhance and improve the surface finish, appearance as well as the mechanical properties of parts produced by additive manufacturing. While it is beneficial to organizations that [...]

Metrology Minute – Relocating a CAD Model for Inspection

Very often, when a part is designed in CAD, in terms of its orientation and origin, it isn’t necessarily where it needs to be oriented in the final assembly. Therefore, inspection values may not reveal the true picture as to what is needed regarding inspection data. Let’s consider this crankshaft below. The CAD designer created this sub-assembly with the part’s origin as shown. Then, any distance or location dimensions shown in the inspection will be relative to this sub-assembly origin. Let’s now go through the steps of relocating the sub-assembly to the correct location in the vehicle so dimensions are evaluated properly. The three green lines below represent the location point and orientation of where the sub-assembly of the crankshaft needs to move. From the CAD tab, select Transform Body. Select the CAD model and select the arrow in the menu to continue forward through the command. We used the Interactive Alignment method to reposition the crankshaft to the proper location in the vehicle. After selecting Interactive Alignment, select the XYZ option. The screen will then divide into two sections. Select the X-Axis option and then select the horizontal vector as shown below. Do the same by selecting the Y-Axis vector and the [...]

Freeform Volumetric Software Reshapes Heads – and Lives

In recent years, volumetric CAD packages have emerged as the tool of choice for medical modeling. Oqton Freeform, one such volumetric CAD package, is well suited to give designers speed and design freedom with complex, organically shaped objects such as those found in the human body. When a defect, deformity, or injury alters cranial bones, surgeons need a unique blend of engineering and artistry to return the human face to its former aesthetics. Advances in volumetric CAD technology are allowing traditional CAD manufacturing principles to meet complex medical modeling needs that formerly couldn’t be handled digitally — like reshaping the human skull. These advances let biomedical engineers digitally sculpt a custom cranial implant or surgical guide with the best fit and function for each patient. A new breed of rapid-product-development firms provides doctors and patients with such surgical guides and custom implants faster and more cost-effectively, thanks to advances in rapid manufacturing techniques and biocompatible materials. Despite readily available digital medical imaging files such as CT scans and MRIs, patient-specific implants and surgical guides are still primarily made by hand in small labs. Organizations usually can’t support volume demand for digital fabrication devices to justify their cost. Labs cut, grind and manually shape [...]

Join Us for the Mastercam 2025 Rollouts

This year, we are making it so easy for you to attend the much-anticipated Mastercam 2025 Rollout! We’re giving you the flexibility to join our event in the way that best suits you. You have the option to either join us in person at one of our offices, or online from your own shop or home. What can be easier? There's no reason to miss this informative event. The Mastercam 2025 Rollout will be August 6th, from 8:00 AM to 2:00 PM EDT. Our live in-person events will be taking place in our offices in: Branchburg, NJ Butler, PA And also at the Mastercam Headquarters in Tolland, CT This is a great opportunity to meet some staff and mingle with fellow Mastercam programmers. And, attending in person gives you the added bonus of free food! The live events include breakfast and lunch, ensuring you stay energized throughout the day. In addition to learning about all the newest Mastercam features, we will also have two brief presentations on other manufacturing solutions that Cimquest offers, such as 3D Printing, 3D Scanning and Reverse Engineering. These presentations will highlight the integration of CAD/CAM and how you can simplify your workflow. Full Agenda 8:00 AM – 8:30 [...]

Exploring the Strengths of Kimya PA Carbon

Exploring the Strengths of Kimya PA Carbon: The Ultimate Nylon-Based Filament for High-Performance 3D Printing In the dynamic world of 3D printing, finding the right material that balances strength, stability, and ease of use can be a game-changer. Enter the Kimya PA Carbon, a nylon-based filament reinforced with carbon fibers, designed to meet the rigorous demands of high-performance applications. This engineering thermoplastic stands out due to its exceptional mechanical properties, making it an ideal choice for creating parts that require high strength and durability. Exceptional Mechanical Properties Kimya PA Carbon is renowned for its impressive mechanical strength and stiffness. The integration of carbon fibers into the nylon matrix significantly enhances its structural integrity, allowing for the creation of parts that can withstand substantial stress and strain. This makes it an excellent material for applications in industries where durability and reliability are paramount, such as automotive, aerospace, and manufacturing. Temperature and Chemical Resistance One of the standout features of Kimya PA Carbon is its excellent resistance to high temperatures (until 120°C) and chemicals. This property ensures that printed parts maintain their performance and dimensional stability even in elevated heat environments. Whether it's under the hood of a car or in a high-temperature industrial setting, [...]