3D Printing Industry Hails Biden’s AM Forward Initiative

A reprint from 3DPrintingindustry.com Leaders from across the 3D printing industry have hailed the potential of President Joe Biden’s AM Forward program to drive the technology’s wider adoption. Launched last week, the initiative is designed to promote 3D printing’s uptake by SMEs as a means of helping better secure their supply chains and revitalizing the US manufacturing sector. Initial participants include industry heavy-hitters like GE Aviation, Honeywell, Lockheed Martin, Raytheon and Siemens Energy, while its 3D printing focus has also drawn praise from stalwarts such as Carbon. “We’re at an undeniable inflection point — bringing digital manufacturing to US businesses will be a critical component to the success of the American economy both now and into the future,” said Carbon CEO Ellen Kullman. “The administration’s acknowledgment of 3D printing to boost the economy is a solid step forward and a proof point that digital manufacturing is critical in addressing our ongoing supply chain challenges and beyond.” “THE AM FORWARD PROGRAM IS FURTHER VALIDATION OF THE URGENT NEED TO REBUILD AGILE MANUFACTURING CAPABILITIES IN THE US” With US inflation at its highest rate in 40 years, and both COVID-19 and Russia’s invasion of Ukraine continuing to disrupt global trade, the fragility of the country’s [...]

MakerBot and Ultimaker Merger will Accelerate Global Adoption of Additive Manufacturing

MakerBot and Ultimaker, two leaders in desktop 3D printing, announced that they have come to a business combination agreement that will accelerate the adoption of additive manufacturing by providing a comprehensive desktop 3D printing ecosystem of hardware, software, and materials. The new entity will be backed by existing investors, NPM Capital and Stratasys (Nasdaq: SSYS), and will benefit from a planned cash investment of $62.4 million to fuel innovation and expansion into new markets. The new company will be led by Nadav Goshen, current MakerBot CEO, and Jürgen von Hollen, current Ultimaker CEO, who will act as Co-CEOs, with Nadav managing operations and R&D and Jürgen managing the commercial functions. “This merger marks an important milestone for Ultimaker and MakerBot,” says Jürgen von Hollen, CEO of Ultimaker. “Innovation and growth are both critical to bringing desktop 3D printing from a specialty technology into mainstream business adoption. The new company will leverage and expand its combined global footprint with sales and operations in the Americas, EMEA and APAC.” “Technological innovation is paramount in growing the availability of easy-to-use professional 3D printing solutions,” says Nadav Goshen, CEO of MakerBot. “By combining our teams and leveraging the additional funding, we can accelerate the development of advanced [...]

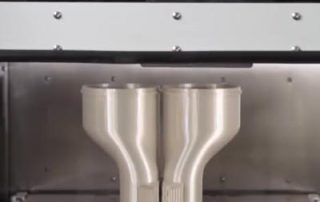

3DGence Industrial Grade 3D Printers

This blog post will take a look at the most cost-effective and accessible Industrial 3D printing platform by 3DGence. Capable of printing high-temp and high-performance materials, this robust solution is geared to accommodate a wide range of demanding industrial applications. The Industry F350 and F421 are based on the traditional FFF printing process, where the extruder heats & deposits a plastic to build your geometry layer by layer. The F350 offers approximately 13” x 13” x 13” build volume while the larger F421 can produce parts that are 15” x 15” x 16”. The 3DGence platform grants engineers access to an open certified materials platform with the widest range of options. They have accomplished this through three swappable print modules that are quick and easy to remove. The M280 is optimized for your standard low-cost thermoplastics which include ABS, ASA, PLA, PET, Nyon and TPU. The M360 is optimized for advanced engineering materials like PC and Ultem. M500 is compatible with high-performance ultra polymers like PEEK and PEKK. All three modules contain reinforced steel components that allow for printing in all types of abrasive carbon reinforcement composite materials. PEEK & PEKK are traditionally used where components must withstand high mechanical loads at high [...]

CNC Machining vs. 3D Printing

This article is reprinted from 3DPrint.com. 3D printers have quietly been transforming production lines at some of the world’s leading manufacturers. Once considered primarily for prototyping; advancements in materials and productivity have made 3D printers a powerful tool for applications beyond prototyping that range from tooling to end-use parts. As these 3D Printers move from R&D onto the shop floor the question that keeps coming up is “Will 3D printing ever replace CNC Machining?” The short answer is no because it doesn’t need to. Both 3D Printing and CNC Machining have their place in manufacturing. The truth is they are friends, not adversaries. Simply put, these are two different tools in your toolbox! Both are useful but do different jobs. The key is to know how to use them for your application. The main difference between the tools is that 3D printing is an additive process while CNC is a subtractive process. 3D printing starts from nothing and builds a part layer by layer. Whereas CNC begins with a stock of material and removes that material until the desired shape is achieved. Here are the advantages of each: 3D Printing Advantages Design Freedom – geometries can be achieved that are otherwise not possible [...]

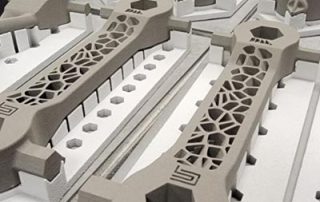

Acceleration of Metal 3D Printing Event

Thank you to all who attended our 3D printing event that took place at our headquarters in Branchburg, NJ last week. This was the culmination of our "Acceleration of Metal 3D Printing" series which introduced this advanced Additive Technology and its various applications. During yesterday's event, attendees were able to tour our new Metal 3D Printing showroom, interact with parts, and network with other participants. Special thanks to Nate Higgins, Co-founder of FreeFORM who shared his journey in the process of taking a concept and developing a path from prototyping to mass commercialization, Stevie Fealtman from Xact Metal, as well as Shannon Morgan and Cory Haas from Desktop Metal. The excitement and enthusiasm of the attendees are proof that Metal 3D Printing is a hot item this year 2022 and will continue to be a hot topic in years to come. As a special treat, all of the event attendees will be receiving one of the sample metal 3D printed parts shown below. We had a second event just like it in the Boston area on May 4th. This one was hosted by ABCorp in their facility in Boston, MA. At this event attendees got to see the Desktop Metal Shop System live, [...]

Electric Vehicles and CNC Machining: What You Need to Know

Electric Car Battery Pack The push for electric vehicles (EVs) is nothing new, but few expected the arms race Tesla would spark in the automotive world with their aggressive development. Now, IHS Markit predicts that 25 percent of all passenger vehicles sold worldwide will be electric by 2030. Others predict that even more will be sold by then. Currently, the inventory of automobiles, in general, is less than demand because of the supply chain issues of 2020 and 2021, leaving the market wide open for accelerated growth. The automotive manufacturers that learned from the pandemic reassessed their production processes to maximize cost containment. Often that meant optimizing their CNC machining approach. Luckily, that exact choice will make it easy to switch from manufacturing mainly internal combustion engine (ICE) vehicles to EVs. That switch will be more difficult for shops that have overly specialized equipment, but investing in the right software in the coming years could put them back on the right path. The most obvious concerns when producing EVs rather than ICE vehicles are reducing weight, achieving the precision necessary for making battery packs, and producing internal components with longer lifespans than their ICE counterparts. The right software and machining centers [...]