This article is reprinted from 3DPrint.com.

3D printers have quietly been transforming production lines at some of the world’s leading manufacturers. Once considered primarily for prototyping; advancements in materials and productivity have made 3D printers a powerful tool for applications beyond prototyping that range from tooling to end-use parts.

As these 3D Printers move from R&D onto the shop floor the question that keeps coming up is “Will 3D printing ever replace CNC Machining?” The short answer is no because it doesn’t need to.

Both 3D Printing and CNC Machining have their place in manufacturing. The truth is they are friends, not adversaries. Simply put, these are two different tools in your toolbox! Both are useful but do different jobs. The key is to know how to use them for your application.

The main difference between the tools is that 3D printing is an additive process while CNC is a subtractive process. 3D printing starts from nothing and builds a part layer by layer. Whereas CNC begins with a stock of material and removes that material until the desired shape is achieved.

Here are the advantages of each:

3D Printing Advantages

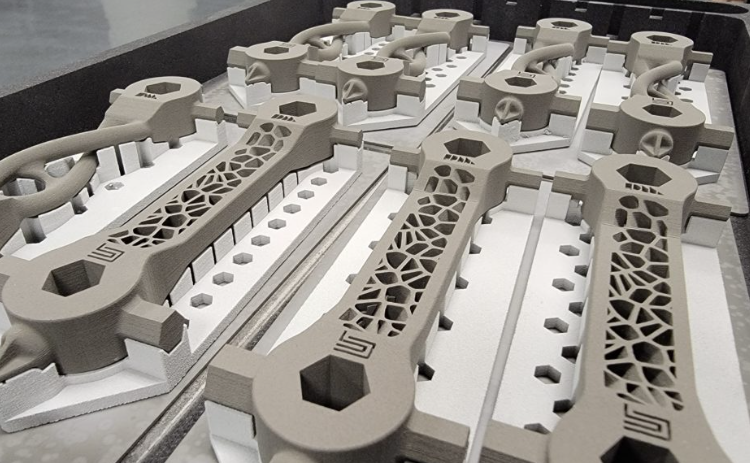

- Design Freedom – geometries can be achieved that are otherwise not possible with traditional manufacturing methods (i.e. complexity is free). This includes:

Part consolidation – assemblies that require multiple parts and fabrication/joining methods can be printed as a single piece. - Lightweighting – 3D printing allows you to put material only where it is needed. You can easily create voids, honeycomb or lattice structures without creating extra steps or energy to remove them.

- Speed – There is minimal time from 3D file to part in hand. Multiple variations can be done on the fly.

- Less Programming Time – Compared to CNC machining, 3D printing requires much less user interaction to create the machine motion path. In some cases, it can be push-button simple but in other cases, it may require much more knowledge such as to create optimum support structures for SLA or DMLS.

- Less Waste – You only use the material you need to produce the part. Even with support structures, the material consumed is often much less than subtractive. In fact, with some additive processes, the left-over material is reusable.

CNC Machining Advantages

- Materials – There is a very broad range of materials available for CNC including metals, plastics, and wood. Generally, for high-volume production 3D printers it is uncommon to have more than a couple or several material options. Even with the limited number sometimes the changeover can be costly and time consuming.

- Tolerance – CNC machining has the ability to machine parts to tight tolerances; frequently 10 to 100 times better than 3D printing.

- Surface Finish – The surface finish of parts from CNC machines is often very good depending on the part geometry, tool geometry, and machining time.

- General Acceptance of the Output – Due to the certification of pre-existing parts and the CNC manufacturing methodology, many industries are more accepting of CNC machined parts.

- Open Architecture – Generally, users of CNC technology purchase their tooling and materials from 3rd party suppliers and enjoy multiple sources for those items; whereas, 3D printer users frequently have to source their supplies from a single source. Most of the time this source being the 3D printer manufacturer. While this is starting to improve, 3D printing has a great deal of catchup to do in this area.

“I think companies need to always be open to change. Not only so that we make quality parts with the machines that we already have, but also looking for ways to improve our capabilities to serve our customers with new ideas and new technology.” Sean Farrell, Dura-Metal

Hybrid (CNC & 3D Printing) Approach Benefits

- Better Parts – Combining additive and subtractive processes gives you the design freedom in 3D printing with the tight tolerances only achievable with CNC machining.

- Better Shop Floor Utilization – By using 3D printing for design iteration, testing, and production of custom tools and fixtures you free up utilization on CNC machines for profitable, predictable jobs.

- Improved Operational Efficiency – By utilizing your machines and equipment for the jobs they are best suited to perform you can extend the life of your machinery and reduce the cost to maintain your equipment.

- Deepen Customer Relationships – Combining 3D Printing with CNC machining can allow you to produce parts that you’d otherwise turn down. It also enables you to suggest new ways of making components that could be more valuable to your clients. This can strengthen your business relationship while also attracting new customers & new revenue.

“Our goal with adding 3D Printing was to improve our machine shop efficiency, light-weight certain parts, and reduce assemblies as much as possible. 3D Printing helped us do all of that.” Adam Duche, Aerotech Industries

Conclusion

3D Printing & CNC Machining can indeed work together to serve your customers better. The first step should always be to decide which technology is best for your part. Both processes have their advantages and both complement each other, which can then provide you and your customers with:

- Increased flexibility and independence

- Time and costs savings

- Expanded manufacturing capabilities

- Improved internal processes

Leave A Comment