A Day of Innovation and Racing at Cimquest’s Derby

On a bright and exciting day, Cimquest opened its doors to guests for a unique Derby event, blending the thrill of racing with the marvels of modern technology. Inspired by the classic “Pinewood Derby,” this event was designed to showcase the innovative solutions Cimquest offers and how these technologies come together to create our very own Derby car. The day began with a guided tour of our facility, where guests were introduced to the various technologies that played a crucial role in building our Derby car. We highlighted the capabilities of our HP, Formlabs, and UltiMaker machines, demonstrating how each contributes to our cutting-edge manufacturing processes. A special highlight of the tour was the display of two golf ball putters, 3D printed on our Xact Metal Machine and Desktop Metal Shop System. These putters not only showcased the precision and versatility of our 3D printing technology but also served as a nod to a previous successful event. Following the tour, guests enjoyed a delicious lunch, providing an opportunity to mingle, share insights, and build anticipation for the afternoon’s main event – the Derby races. The atmosphere was filled with excitement as participants prepared their cars for the competition. The races were the highlight [...]

Enhancing Radiation Shielding Using 3D Printing, Scanning, and Geomagic Design X

Enhancing Radiation Shielding Using 3D Printing, Scanning, and Geomagic Design X Nuclear plants could become the main source of clean energy, but their success is tied to preventing hazardous radiation. Canadian electric company Bruce Power, with a nuclear power station on Lake Huron, embarked on developing a novel radiation shielding approach. The company uses a 3D scanning and 3D printing workflow with tungsten-impregnated filament to make custom shielding components. Barely a year after the initiative was launched, a prestigious award and interest from peers attest to the value of this innovation. A key driver of this initiative is Douglas Neil, a Radiation Protection Technician who has been working at Bruce Power for nearly 18 years. For the past year, he’s been entirely focused on designing and printing custom radiation shielding. They measure the area that requires shielding – either with a 3D scanner or digital calipers – design the component in Geomagic Design X and print it in tungsten-impregnated plastic powder. The entire production is carried out in a cubicle at the Bruce Power office. No shop floor, no specialist additive engineer, no expensive machinery, just a 3D scanner, 3D reverse engineering software, and two consumer-level printers. They acquired the scanner and the [...]

Revolutionizing 3D Printing: The Formlabs Form 4

In a recently published article by Time.com titled "The Best Inventions of 2024," Time.com discusses that while 3D printing is a game-changing technology, overall, it's pretty slow. That is all changed, however, with the Formlabs' Form 4 and now Form 4L. In their article they discuss how this desktop-sized 3D printer boasts print speeds up to five times faster than its predecessor. It uses powerful LED lights and a custom LCD to turn liquid resin into solid layers quickly. Projects that once took overnight can now be completed in hours, making it a viable replacement for traditional injection molding. This speed allows for multiple iterations in a day, enabling hardware developers to take more design risks and bring better products to market1. The Formlabs Form 4 is a game-changer in the world of 3D printing, offering unmatched speed and efficiency. With the ability to deliver parts in under two hours, it significantly outpaces previous models. This is made possible by its advanced LED and LCD technology, which rapidly cures resin layers, ensuring quick and precise prints. In terms of accuracy and reliability, the Form 4 excels. It maintains high dimensional accuracy and surface finish, which is crucial for creating detailed prototypes and end-use [...]

Major 3D Scanning Civil Engineering and Infrastructure Opportunities

Major 3D Scanning Civil Engineering and Infrastructure Opportunities Precision is crucial in civil engineering, but measuring and surveying can be time-consuming. 3D scanning has revolutionized this by providing accurate, data-rich models quickly, enhancing efficiency in various tasks. In this blog, we explore key areas where 3D scanning can improve precision, efficiency, or insight. Bridges and Tunnels Bridge Bearings: 3D scanning in different seasons shows structural movement, helping identify and replace faulty bearings. Bridge Strikes: Scanners determine if a truck exceeded height limits or if the bridge has settled. Bridge Repair: 3D scanning creates accurate CAD models for planning repairs, extending the lifespan of aging infrastructure. Roads and Highways Safety Inspection: Mobile 3D scanning must flag low barriers caused by resurfacing. Maintenance and Repair: It must identify road dips and create cross-sectional drawings for accurate material estimates. Industrial Facilities Chimney Inspection: 3D scanning must provide complete data on chimneys. Cooling Towers: It must monitor for cracks and safety issues. Furnaces: It must deliver precise data on furnaces without risking survey teams. General Infrastructure Safety Structures: 3D scanning must reverse engineer and remanufacture assets like fire escapes. Complex Assets: It must create accurate models for unique structures. RAAC Inspection: It must assess degradation in reinforced [...]

Design X Go: Reverse Engineering for Mastercam Has Arrived

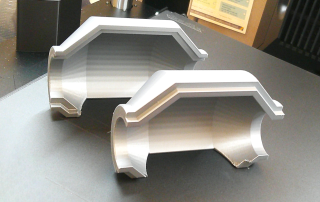

Design X Go: Reverse Engineering for Mastercam Has Arrived Join Cimquest or this educational webinar to explore how Design X Go can serve as both a 2D and 3D CAD system as well as a reverse engineering tool to create machinable CAD models from scan data (mesh or point cloud) and is the bridge from scan or point cloud data to fully machinable models in Mastercam. Recap of our Design X Go Webinar – Reverse Engineering for Mastercam Applications This week, we introduced the brand new Design X Go (DXGo) product in a 60 minute Webinar. So I decided to make this month’s Metrology Minute focused on this awesome new reverse engineering product and how it can add value to any Mastercam user. I wanted to take a moment here to thank Steve Weaber, from our awesome Mastercam support team, who assisted me by providing the Mastercam toolpath files used for the Webinar. We presented three scenarios where DXGo can greatly enhance the productivity of a Mastercam user. 3D Modeling without the presence of a mesh or point cloud – DXGo can function very much like the Part Modeler of any of the modern-day CAD products. We demonstrated the [...]

SLA 3D Printing – How Pixel Size Impacts Accuracy, Feature Size, Surface Finish

SLA 3D Printing - How Pixel Size Impacts Accuracy, Feature Size, Surface Finish In the realm of 3D printing, resolution is a frequently discussed but often misunderstood topic. With the rise of various 3D printing technologies and manufacturers, the conversation around resolution has become even more complex. One critical aspect of this discussion is pixel size, especially in the context of Stereolithography (SLA) and Masked Stereolithography (MSLA) 3D printers. Pixel Size and Its Importance Pixel size in 3D printing refers to the smallest feature that a printer can reproduce within a single layer. In MSLA 3D printers, which use an LCD screen to selectively mask light and cure liquid resin, the resolution is typically measured by the number of pixels across the screen’s long axis. The general assumption is that smaller pixels result in higher resolution and better print quality. However, the reality is more nuanced. Beyond Pixel Size: What Really Matters While pixel size is an important factor, it is not the sole determinant of print quality. Surface finish, dimensional accuracy, and minimum feature size are the tangible outcomes that most users care about. These characteristics are influenced by a combination of factors, including material properties, optical settings, and mechanical consistency. For [...]