Formlabs launches large format 4L series; opens up SLA & SLS 3D printers to third party materials.

Formlabs launches large format 4L series; opens up SLA & SLS 3D printers to third party materials. Formlabs, a leader in 3D printing technology, has announced the launch of the Form 4L and Form 4BL, their latest large-format SLA 3D printers. These new models promise blazing fast speeds and exceptional print quality, catering to a wide range of applications from prototyping to production. Alongside these printers, Formlabs is also opening its SLA and SLS platforms to third-party materials, providing users with unprecedented flexibility and control. Key Features of Form 4L Unmatched Speed: Capable of large-scale prints in under six hours, with printing speeds up to 80 mm/hour. Large Build Volume: Nearly five times larger than the Form 4, allowing for the production of bigger parts and higher volumes. High Efficiency: The new cartridge design reduces plastic waste by 63% and speeds up resin dispensing. Versatile Materials: Compatible with over 23 materials, including durable, rigid, biocompatible, and flame-retardant options. Comprehensive Ecosystem: Includes new accessories like the Resin Mixer, Resin Tank, Build Platform, Resin Pumping System, and Finish Kit and Form Wash L for post-processing. Learn more about the Form 4 Series 3D Printers Developer Platform and New Material Pricing Formlabs is [...]

3D Scanning for Civil Engineering & Infrastructure Maintenance Overview

3D Scanning for Civil Engineering & Infrastructure Maintenance Overview Civil engineering and infrastructure are complex and costly. Maintenance of structures like highways and bridges requires addressing operational complexity, material scale, and safety. 3D scanning provides accurate site information to tackle these challenges. This blog explores how 3D scanning aids these projects, its benefits, and the technology involved. Uses of 3D Scanning in Civil Engineering and Infrastructure 3D scanning in civil engineering involves assessing large infrastructure. Common applications include: As-built modeling: Captures accurate models of structures for inspections and repairs. Reverse engineering: Recreates accurate 3D models of structures with lost or incomplete documentation. Mobile inspection: Evaluates extensive roadways or rail lines for safety concerns. Monitoring: Tracks progress during large-scale projects. Advantages of 3D Scanning 3D scanning is preferred for on-site data capture due to: Access: Captures data from hard-to-reach structures. Safety: Reduces exposure to dangerous areas. Speed: Faster than manual measurements, improving efficiency. Accuracy: Provides highly accurate data, minimizing human error. 3D Scanning Devices for Civil Engineering Depending on the application, teams may use different scanners: Terrestrial laser scanners: Stationary devices using LiDAR to capture detailed 3D models from a fixed position. Metrology-grade laser scanners: Portable devices capturing high-detail data quickly, meeting rigorous accuracy [...]

Design X Go: Reverse Engineering for Mastercam Has Arrived

Design X Go: Reverse Engineering for Mastercam Has Arrived Join Cimquest or this educational webinar to explore how Design X Go can serve as both a 2D and 3D CAD system as well as a reverse engineering tool to create machinable CAD models from scan data (mesh or point cloud) and is the bridge from scan or point cloud data to fully machinable models in Mastercam.

How to Make Your Own Custom Jigs and Fixtures

How to Make Your Own Custom Jigs and Fixtures In the world of manufacturing, precision and efficiency are paramount. One of the key tools that help achieve these goals are jigs and fixtures. These essential devices hold, support, and secure products during various processes, ensuring consistency and quality. Traditionally, creating jigs and fixtures could be time-consuming and costly, but with the advent of 3D printing, manufacturers now have a powerful tool to produce these aids in-house. Understanding Jigs and Fixtures Jigs and fixtures might sound similar, but they serve distinct purposes. Jigs are tools that hold the workpiece and guide the equipment to ensure proper alignment during operations like drilling or milling. Fixtures, on the other hand, are devices that hold the workpiece in place during secondary processes such as welding or assembly. Both are crucial for maintaining high part quality and operational efficiency. The Advantages of 3D Printing 3D printing has revolutionized the way manufacturers approach the creation of jigs and fixtures. Here are some of the key benefits: Customization: 3D printing allows for the creation of highly customized jigs and fixtures tailored to specific parts and equipment. This level of customization ensures a perfect fit and optimal performance. Cost Reduction: Producing [...]

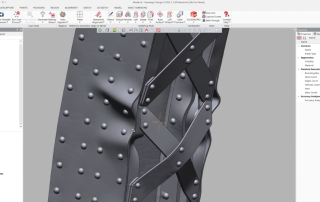

Golden Gate Bridge Replica: Crafted with 3D Scanning and Geomagic Design X

Golden Gate Bridge Replica: Crafted with 3D Scanning and Geomagic Design X San Francisco’s landmark captivates people. “Everyone who visits San Francisco goes to see the Golden Gate Bridge. They want to see it from all sides and always to be close,” says 3D scanning specialist Marcio Adamy. He’s also enchanted by it. “Every time I go back to the bridge, which is often, I learn more about it. I’ve learned about the people who work there and their love for it. They call it ‘Goldie’. And that rubbed off on me too. I love the bridge. I think it’s an amazing place. This is why I decided to scan the monument,” he says. Adamy refers to an art piece near one of the bridge’s foundations, shaped like a slightly squished pillar. Built in 2013, it uses original material and is painted the same color. Reverse Engineering Challenge Most see the object as an artistic tribute. Adamy saw a reverse engineering challenge and created a miniature 3D-printed memento of the bridge. He used an Artec Leo scanner, stored in a backpack he loves. “I could not reach certain areas with the scanner due to the angle and field of view. If I put [...]

Understanding Refresh Rate in SLS 3D Printing

Understanding Refresh Rate in SLS 3D Printing Selective Laser Sintering (SLS) 3D printing is a powerful technology that allows for the creation of high-quality, industrial-grade parts. One of the key factors in achieving optimal print quality and efficiency with SLS printers, such as the Formlabs Fuse Series, is the refresh rate. The refresh rate refers to the ratio of new powder to recycled powder used in each print cycle. This balance is crucial because it impacts both the material properties of the printed parts and the overall cost-effectiveness of the printing process1. The refresh rate is adjustable, allowing users to fine-tune it according to their specific needs and workflows. For instance, a 100% refresh rate means using entirely new powder, while a 0% refresh rate would use only recycled powder. However, using recycled powder over many cycles can degrade material properties, so finding the right balance is essential. Formlabs provides recommended refresh rates for their SLS powders, but users can tweak these settings to optimize their processes1. Choosing the right refresh rate involves considering several factors, including packing density—the arrangement of parts within the build chamber. Higher packing densities mean less unsintered powder, which can be recycled more efficiently. For example, if the packing density is [...]