Turning an Organic Toy Design into a Manufacturing-Ready Model

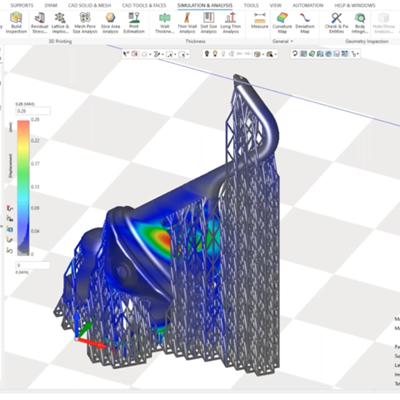

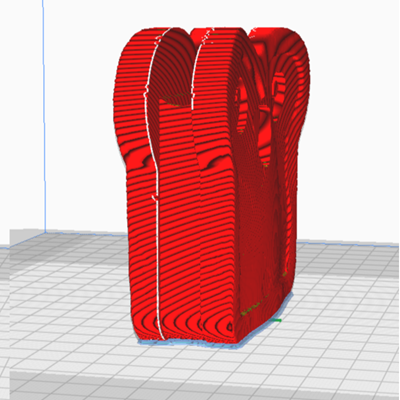

Today's toy aisles showcase a wide range of shapes, from realistic animal figures to imaginative cartoon characters. Most of these toys are made of plastic, with their creation involving two primary steps: design and manufacturing. The challenge of designing toys is compounded during the manufacturing stage. Plastic injection molding is the most common method used, where detailed 3D designs are turned into molds for mass production. Effective software plays a crucial role in this process, [...]