Welcome to the Cimquest Blog!

Check here often to find Cimquest, Mastercam and 3D Printing happenings, product offerings and update info along with general Industry trends and breaking news.

June 2024

Why Post-Processing Is Important in 3D Printing

A reprint from https://www.3dnatives.com/

When we talk about 3D printing, it goes without saying that most would think first about the actual printing process. However, additive manufacturing comprises several stages, from modeling to final part, including design and optimization, slicing, 3D printing and post-processing. As post-processing is the final step, carried out after additive manufacturing of a part, it is the one that […]

Analyze Large Bores with Control X Geometry Deviation

The Geometry Deviation tool in Control X may be used to compare all the parameters of an analytic feature in a scan to the nominal CAD model. This tool provides the ability to thoroughly analyze cylinders whereby the values for both the nominal CAD model and the paired (scan) data are compared. In many cases, the most common feature to check is a cylinder. In this Metrology Minute we are going to show you how […]

Swing into the Future: 3D Printing’s Role in Modern Golf

In the world of golf, precision and innovation go hand in hand. The quest for the perfect putter has led enthusiasts and professionals alike to explore various materials, designs, and technologies. Enter the realm of 3D printing—a groundbreaking technology that is redefining the boundaries of golf equipment. Please join us at one of our upcoming events:

“Cimquest Manufacturing Expo: Teeing Up Innovation” on June 11th at our headquarters, […]

May 2024

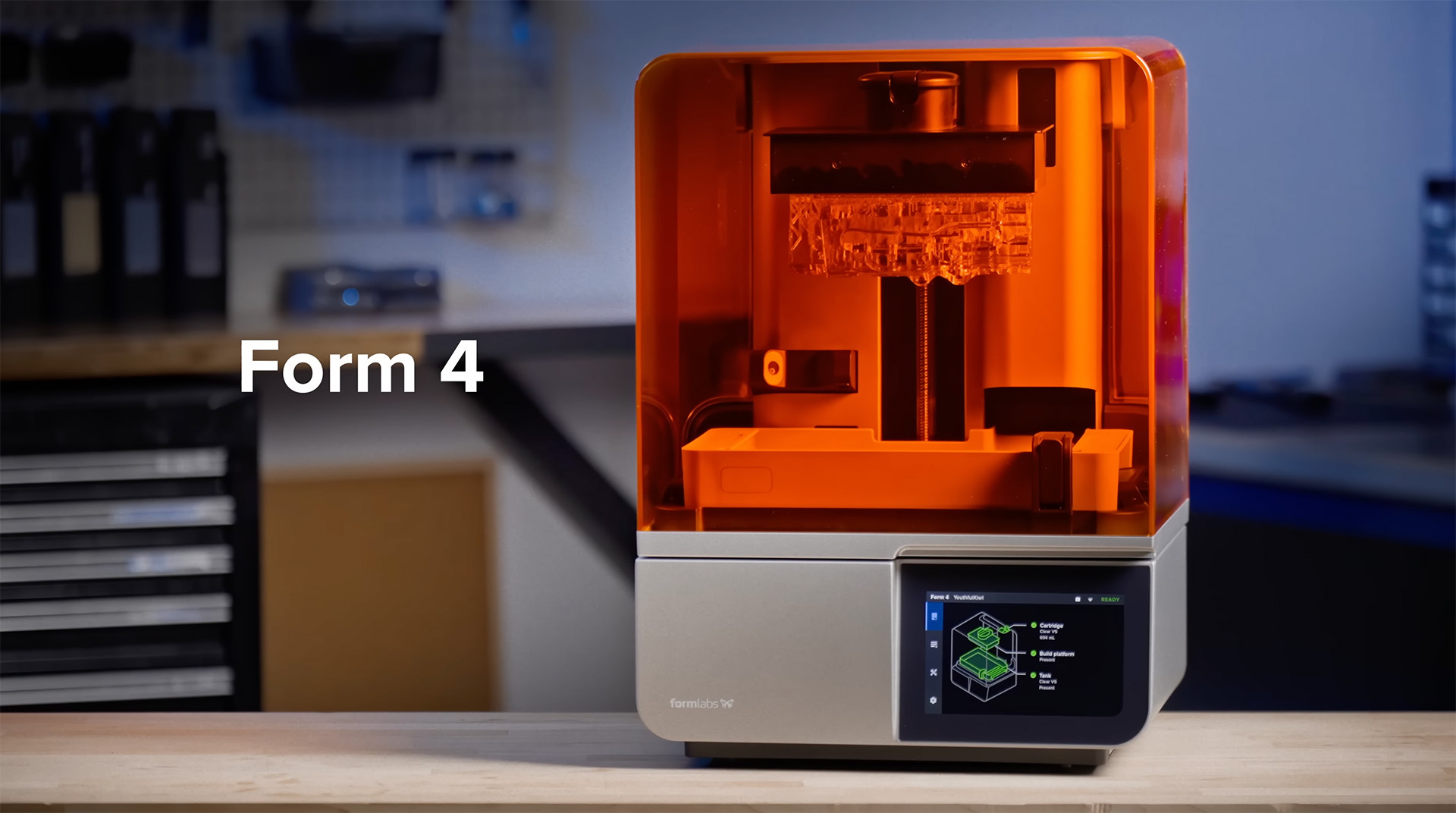

The Intuitive and High-Speed Form 4 by Formlabs

Join us for an exclusive webinar where we delve into the world of cutting-edge 3D printing with the Formlabs Form 4. The Form 4 provides everything you’d expect from a Formlabs 3D printer, except now it does it 4x faster. The new Form 4 is intuitive, meaning anyone can learn in just 15 minutes. It is reliable, has an […]

Cimquest Manufacturing Expo: Teeing Up Innovation

Get ready to swing into the future with an array of captivating presentations and interactive experiences!

You are invited to an extraordinary event that combines cutting-edge technology with the timeless charm of golf: Cimquest Manufacturing Expo: Teeing Up Innovation!

Event Details:

Tuesday, June 11th, 2024

8:30 AM – 3:45 PM

Cimquest Headquarters: 3434 US-22, Branchburg, NJ 08876

Get ready to immerse yourself in a world where innovation knows […]

Overview of Silicone Molding 3D Printed Tooling

Traditional molds for silicone part production are CNC machined from blocks of aluminum or steel. These include two-part or multi-part injection molds for liquid silicone rubbers (LSR), or single cavity compression molds used with a heat-cured rubber (HCR) silicone sheet that is cured under pressure and high temperature. Normally these types of metal molds are used in mass production. However, when employed for prototyping, lead times of several weeks and upfront tooling costs of hundreds […]