Welcome to the Cimquest Blog!

Check here often to find Cimquest, Mastercam and 3D Printing happenings, product offerings and update info along with general Industry trends and breaking news.

February 2024

Utilizing Construction Features for Theoretical Intersections in Control X

Inspection drawings will often have dimensions created to a theoretical intersection. What this means is that the dimension references one or more points in space that aren’t physically on the model. What do you do in situations like this? Let’s explore this in the example below.

Using the screenshot below, let’s assume that we need to dimension to locations in space where these lines would theoretically intersect if extended.

![Utilizing Construction Features [...]

</p srcset=](https://cimquest-inc.com/wp-content/uploads/2024/02/theoreticalintersections.png)

What’s the Value of a Multi-purpose Tool Like Metal Binder Jet 3D Printing?

Just like there’s no one tool to fit every job, 3D printing isn’t a panacea that’s right for every job either. And while the benefits of binder jet 3D printing can often be measured – customers routinely reduce the weight of their parts by 30 – 40% using our technology – much of the return on investment (ROI) of binder jetting lies in the complex intangibles and specific […]

January 2024

3D Printing Helps Preserve A Saber-Toothed Salmon

Reprint from OPB

A saber-toothed salmon, as depicted by artist Ray Troll. The mural is part of the University of Oregon Museum of Natural and Cultural History. – University of Oregon

A saber-toothed salmon, as depicted by artist Ray Troll. The mural is part of the University of Oregon Museum of Natural and Cultural History. – University of Oregon

For years, museum conservators and paleontologists have yearned for a way to duplicate fragile fossils without damaging them. Now scientists with the University of Oregon say they have […]

Icam Students Working with Kimya 3D Filaments

KIMYA X Icam Bretagne: the students from Icam – Ecole de Production are working with Kimya 3D filaments

Since its establishment in 1898, Icam has been expanding in France and globally, while remaining rooted in its values: audacity, trust, freedom, responsibility, solidarity, and collective success. Its essential mission is to educate engineers who are free, aware, committed, and active in their lives. All […]

Advantages of Additive Manufacturing Repair

The manufacturing industry has witnessed a revolutionary transformation with the advent of additive manufacturing, which has introduced innovative production solutions. In the field of repairs, additive manufacturing, particularly with Wire-DED systems, presents numerous notable advantages compared to conventional repair methods.

The manufacturing industry has witnessed a revolutionary transformation with the advent of additive manufacturing, which has introduced innovative production solutions. In the field of repairs, additive manufacturing, particularly with Wire-DED systems, presents numerous notable advantages compared to conventional repair methods.

Cost-Effectiveness: Repairing parts using additive manufacturing can be highly cost-effective. Traditional repairs often involve manual processes which can be time-consuming and expensive. Moreover, […]

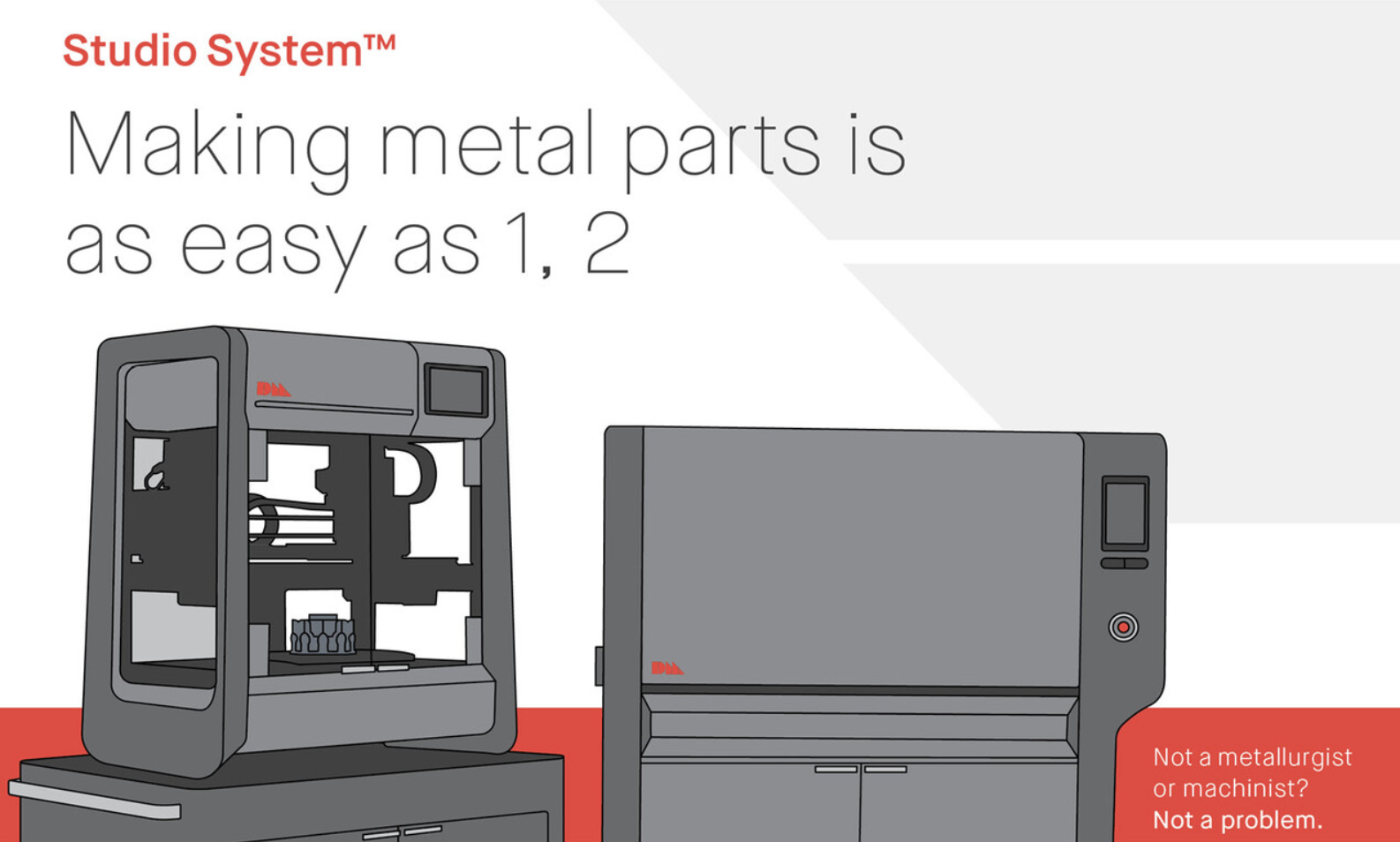

Metal 3D Printing Parts is Easy

Join Desktop Metal’s team of experts for a walkthrough of the metal 3D printing process while reviewing operational information like safety procedures and waste requirements to gain a better understanding of how easy 3D printing a variety of metals can be.

Webinar Details:

Date: January 23rd, 2024

Time: 11:00 AM EST

Metal 3D printing is a transformational technology – […]