Desktop Metal and Evonik Recently Expand Partnership

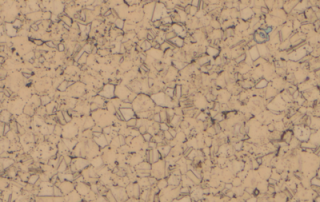

Companies report qualification of photopolymer on large-format additive manufacturing 2.0 systems. A reprint from Digital Engineering247.com Evonik INFINAM ST 6100 L printed on ETEC hardware from Desktop Metal is made for production of molds, models and tooling. Image courtesy of Business Wire. Desktop Metal and Evonik, a materials provider in 3D printing technology based in Germany, report their expanded collaboration on photopolymer and materials development with the qualification of INFINAM ST 6100 L [...]