KIMYA X Icam Bretagne: the students from Icam – Ecole de Production are working with Kimya 3D filaments

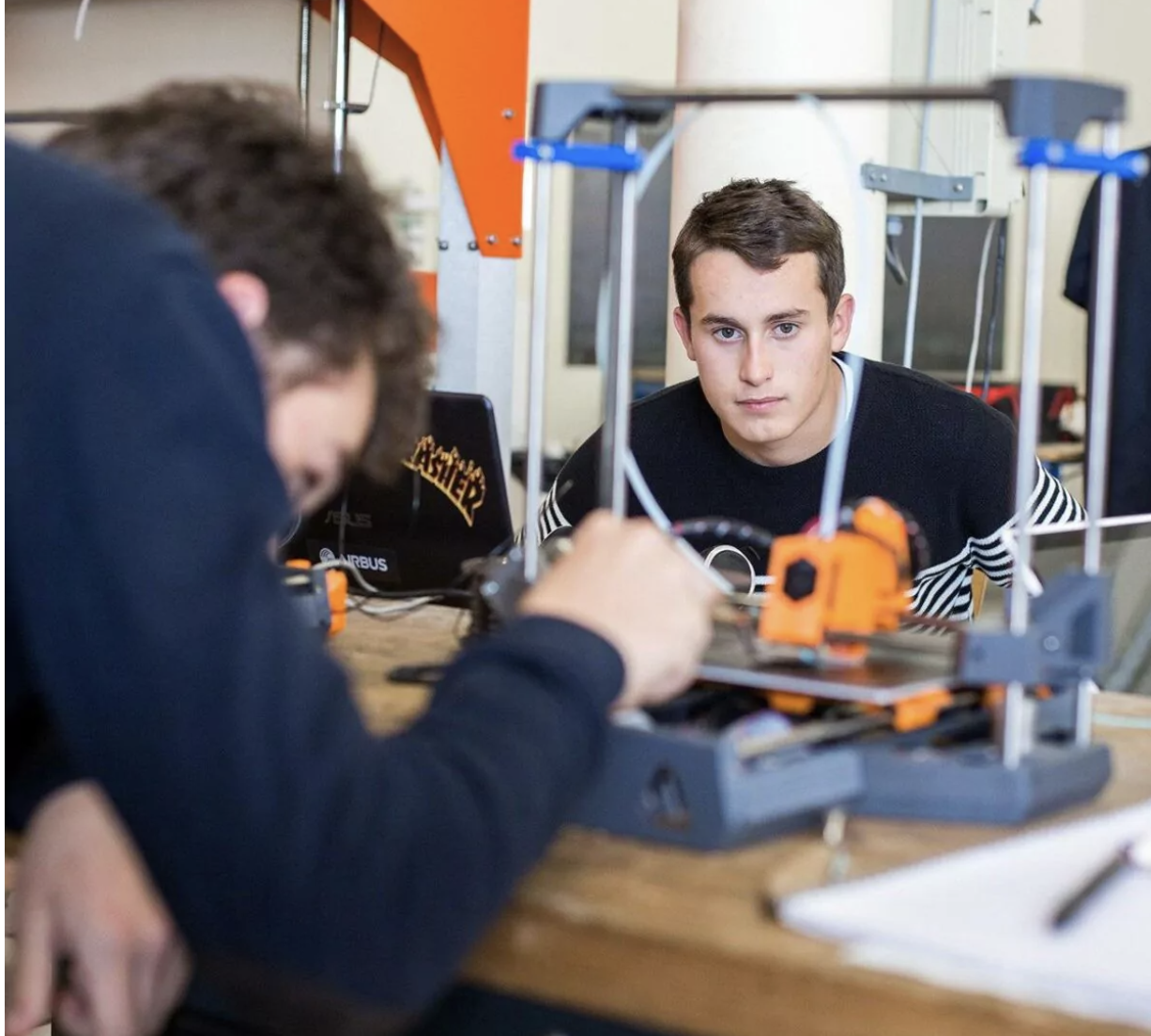

Since its establishment in 1898, Icam has been expanding in France and globally, while remaining rooted in its values: audacity, trust, freedom, responsibility, solidarity, and collective success. Its essential mission is to educate engineers who are free, aware, committed, and active in their lives. All programs at Icam are designed to develop these qualities, which are the common denominator among all students and alumni. The Icam Production School, based in Vannes, welcomes young people aged 14 to 18 who have not found their path in the traditional school system. They are invited to undergo a highly practical training to rekindle their desire to learn and earn a diploma: a CAP in Production Installation Management. Through a machine park consisting of about twenty 3D printers, laser cutters, and machining centers, they work daily to meet the needs of industrial clients.

KIMYA Invests in the Education Sector

The use of Kimya filaments addresses the specific technical needs of industries, aiming to integrate them into industrial projects carried out by students and future professionals of the Icam Production School in Brittany.

“The choice of Kimya filaments was made due to their technical characteristics, the variety of material range, and the exceptional quality of these filaments,” says Simon Lamberdière, Head of the Icam Production School in Brittany.

Three Applications with Kimya Filaments

Through various industrial projects undertaken by the production school, Icam has identified three filaments that meet their regular needs:

- In response to the needs of a company specializing in surface treatment and powder coating, Icam committed to designing masking protections to spare areas to be painted, eliminating the need for the operator to use masking tape. To meet this demand, Icam chose the Kimya TPU-92A filament for its ease of printing and its ability to resist temperatures. This filament also has high elasticity (up to 350%) and great resistance to outdoor environments.

- The production school also worked on the manufacture of pillboxes for a company specializing in the production of dietary supplements. The goal of the pillbox is to eliminate the need for operators to count pills by hand, while improving the efficiency of the process. Icam chose the Kimya PETG-S filament to meet the EU 10/2011 standard and for its resistance to detergents and ability to withstand a temperature of 60°C, allowing dishwashing of the pillboxes after each production. This filament provides a balance between flexibility and mechanical resistance and can withstand high temperatures, up to 80°.

- Finally, in response to the request of an industrial looking to design a system for flipping electronic cards, Icam chose the Kimya ABS-ESD 3D filament for its protection against electrostatic discharges and its high resistance to shocks. It is a lightweight, rigid, and easy-to-print material with surface resistivity ranging from 1×10^7 to 1×10^10 Ω/sq according to the ASTM D257 test standard.

“Thanks to these solutions adapted to the final applications of our clients, KIMYA demonstrates its commitment to innovation. Kimya filaments emerge as innovation catalysts, propelling the realization of ideas,” concludes Simon Lamberdière, Head of the Icam Production School in Brittany.

For more details on Kimya materials, please click below.

Leave A Comment