The Intuitive and High-Speed Form 4 by Formlabs

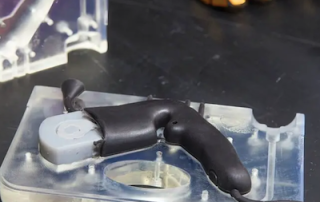

Join us for an exclusive webinar where we delve into the world of cutting-edge 3D printing with the Formlabs Form 4. The Form 4 provides everything you’d expect from a Formlabs 3D printer, except now it does it 4x faster. The new Form 4 is intuitive, meaning anyone can learn in just 15 minutes. It is reliable, has an unmatched print success rate, and is so accurate that it rivals infection-molded parts. Come take a [...]