Innovative Implant Design: From Imaging to Surgical Application

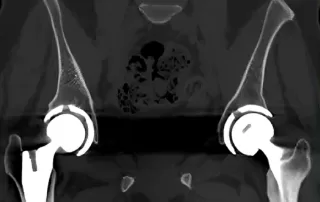

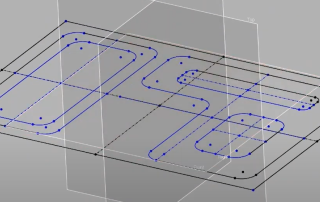

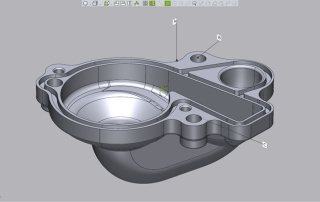

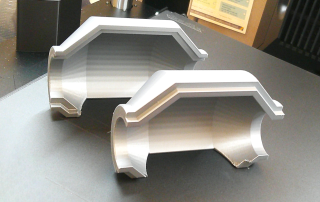

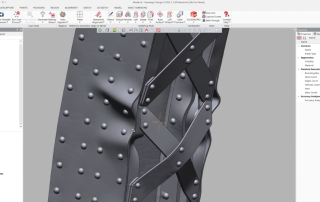

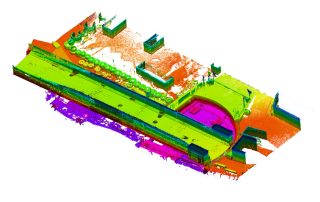

Innovative Implant Design: From Imaging to Surgical Application Hip replacement is common for osteoarthritis, using off-the-shelf acetabulum cups. However, some patients need bespoke implants due to complex conditions like previous surgeries or extensive hip damage. Complex hip replacements pose surgical challenges due to scar tissue, distorted anatomy, fragile or dead bone, and tumors. Bespoke implants require unique bone preparation and precise fitting, often through small incisions and avoiding nerves and blood vessels. Accurate design and [...]