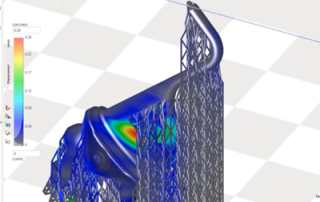

Design X Go – Reverse Engineering for Mastercam has arrived!

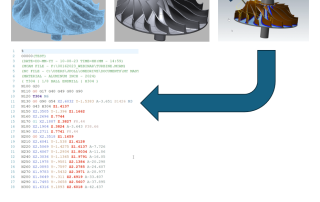

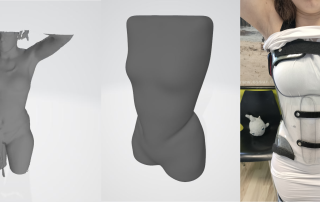

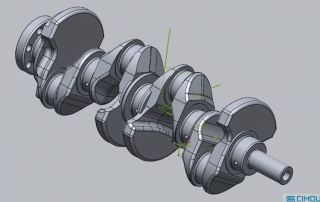

Design X Go – Reverse Engineering for Mastercam has arrived! The ‘Bridge’ from Scan or Point Cloud data to fully machinable models in Mastercam If you’ve ever programmed a Step file that was ‘AutoSurfaced’ from a mesh or point cloud, you’ve likely experienced the many challenges associated with this process. Design X Go supports traditional CAD modeling capabilities to generate the most basic, 2-axis part to the most involved, multi-axis part, from scan data. [...]