Stratasys Highlighted Additive Manufacturing at Composites Europe

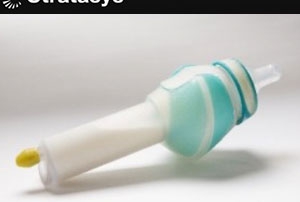

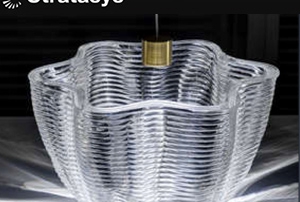

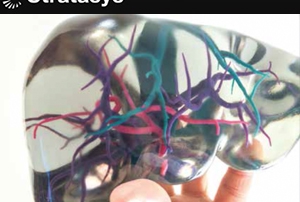

Composites Europe, which took place in September 2015 in Stuttgart, Germany, saw 3D printing provider, Stratasys, demonstrated how its additive manufacturing technology is transforming the face of manufacturing within the aerospace and automotive sectors. Showcasing a spectrum of prototype and production-parts, Stratasys invited visitors to witness how its engineered plastics are meeting the demand for lightweight parts with enhanced functionality across a multitude of aerospace and automotive applications. Recent Stratasys customer announcements highlighting these financial and [...]