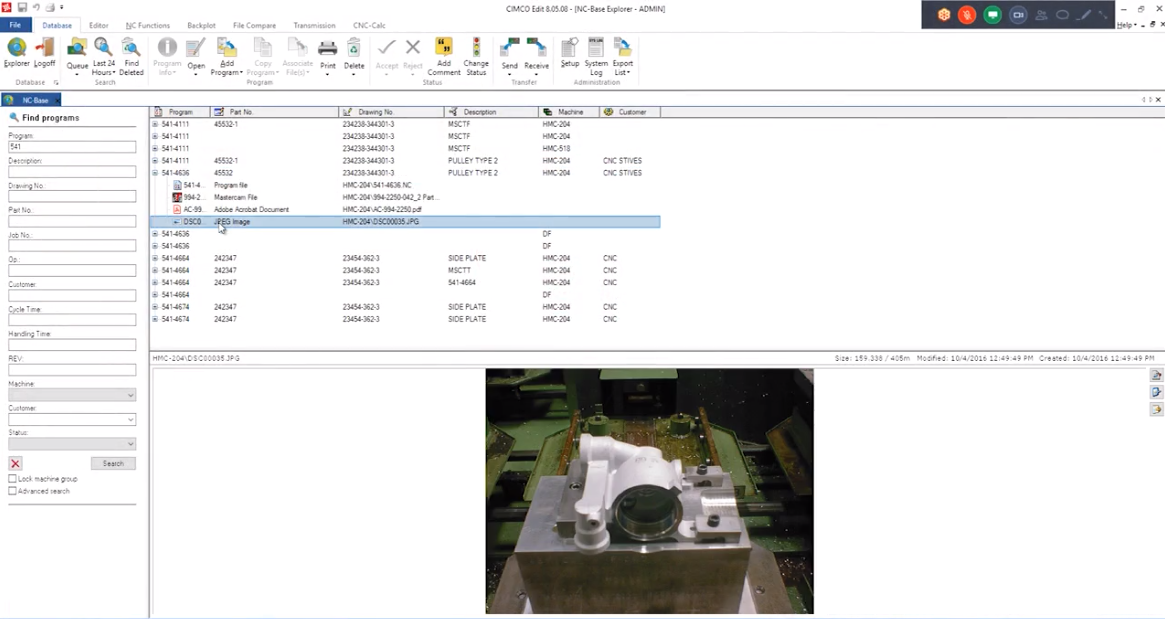

Cimco’s NC Base is the next step in machine shop automation to complement the powerful DNC Max software. NC Base is a CNC program management tool that enables you to manage your part programs as well as any associated documents related to a particular program.

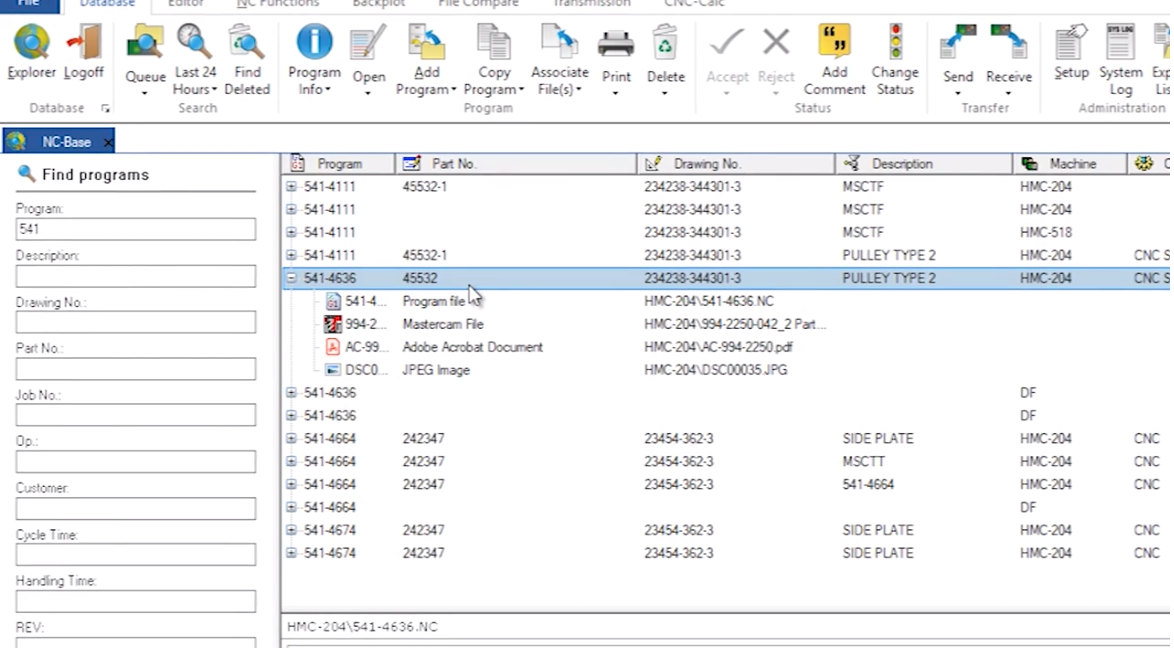

NC Base provides a highly integrated part program search tool that enables complex queries to ensure the correct documents and correct part program version or revision are selected for production. Shop personnel can no longer accidentally grab the wrong shop documentation or worse, the wrong part program as all related data is stored and linked together in this powerful database-driven tool.

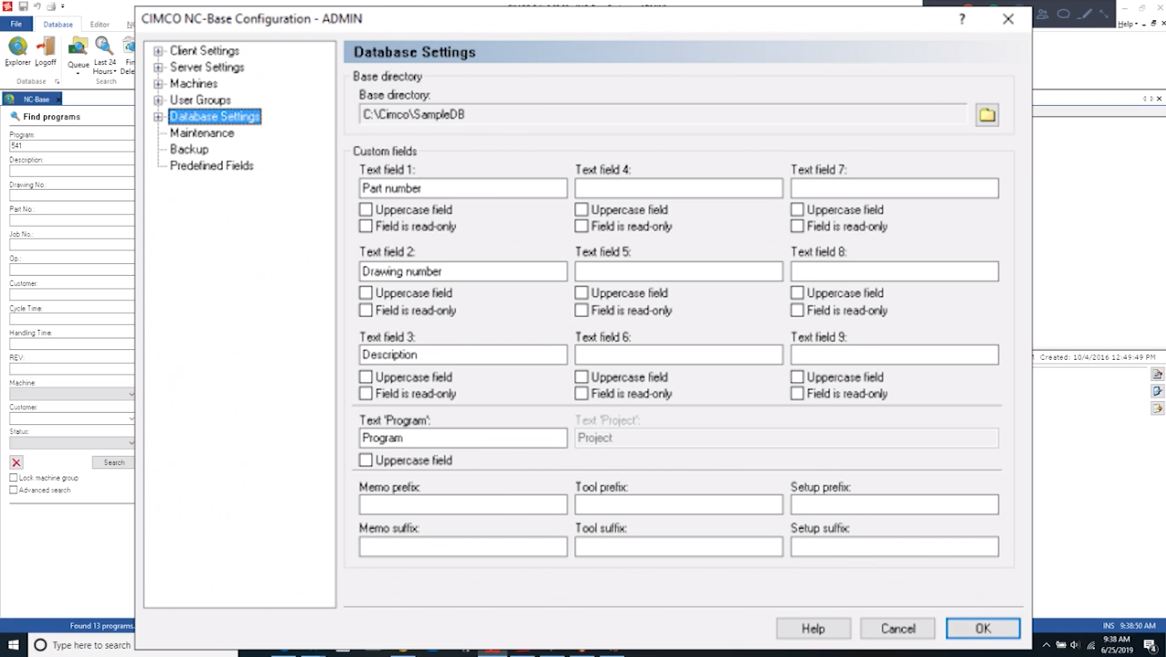

A SQL relational database is the underlying backbone of NC Base, although a user doesn’t need to have any database programming experience to master NC Base. The user interface integrates NC Base into the very popular Cimco Editor seamlessly. So all of the NC Base functionality is accessed through perhaps the most common G-Code Editor in our industry today, and the end user setup is simply checkboxes and dropbox selections.

NC Base enables you to send part programs to the shop floor, along with any necessary and related documentation, such as tool lists, pictures or even videos of complicated setups, fixturing instructions and so on. An NC Base client may view any of the documents on the shop floor or they may be printed out from any workstation running NC Base.

Virtual folders are easily assembled and stored as well as track all activity related to a particular part program, always ensuring the correct documentation accompanies the correct part program.

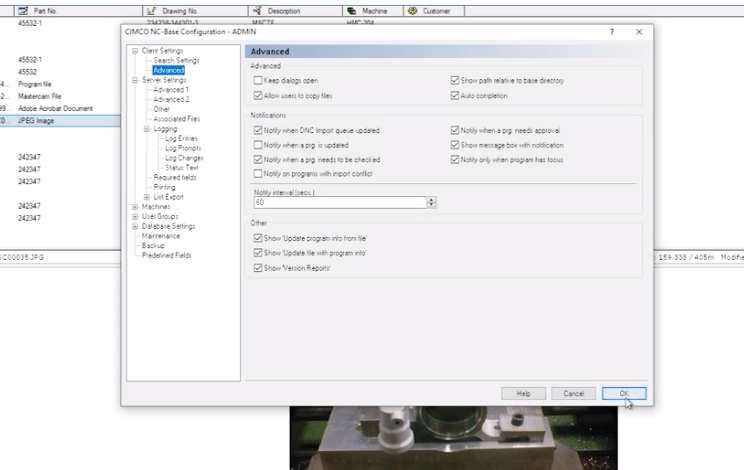

As you can see, NC Base combines sophisticated software tools with easily customizable data fields, production document management, backup and approval controls, locking controls, user/group management and complete integration with the Cimco DNC Max product.

For more details on Cimco products, please click the button below.

Leave A Comment