How 3D Printing Customized Jigs and Fixtures Saves Rutland $60,000 Per Year

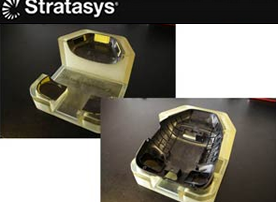

5 Jan. 2015 by Stratasys Staff Rutland Plastics is a custom injection molding company located in Rutland, United Kingdom that produces products for a wide range of companies and industries. Because each project is unique, Rutland must create complementary jigs and fixtures to position and hold the project’s components during manufacturing operations like assembly, gluing, drilling, and measuring. Now thanks to Stratasys 3D printing, creating a steady stream of assembly tools 100% customized for each [...]