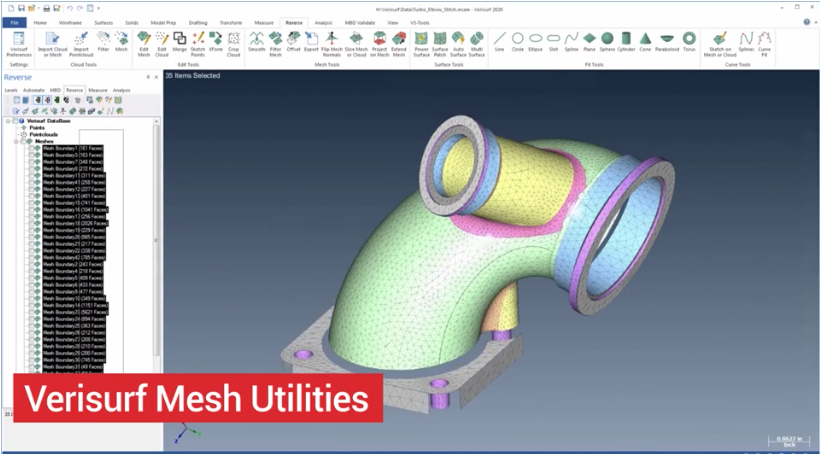

The powerful Verisurf Mesh utilities allow you to create high-quality meshes for 3D printing, machine from STL, and use as nominal models for inspection.

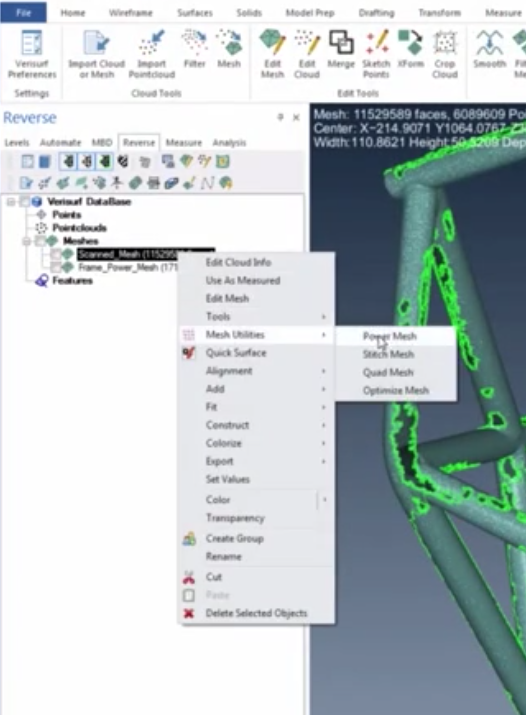

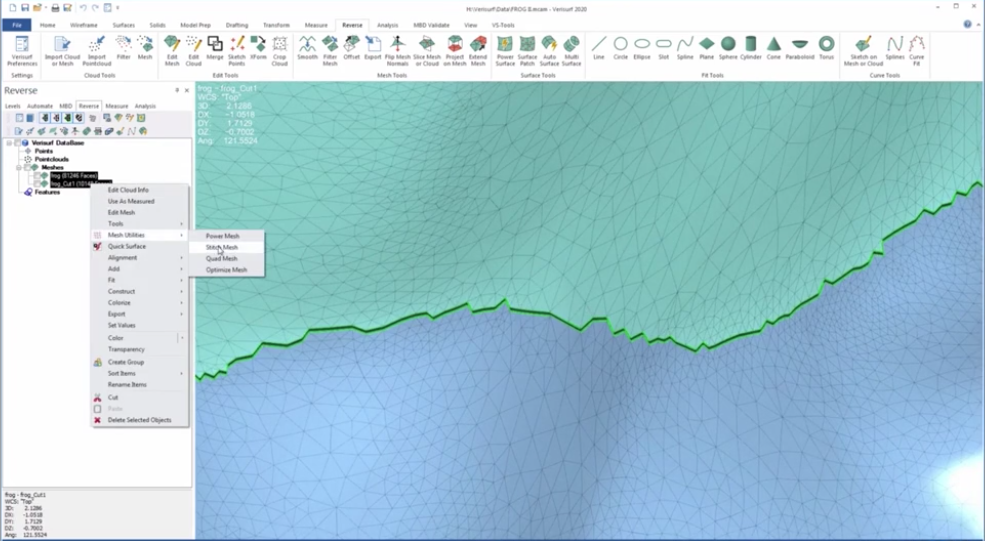

Power Mesh simultaneously can create, merge, clean up, refine, smooth, hole fill, and extend the mesh. Advanced options control mesh density and can close mesh volume. Power Mesh can create water-tight mesh, a natural first step in any reverse engineering workflow.

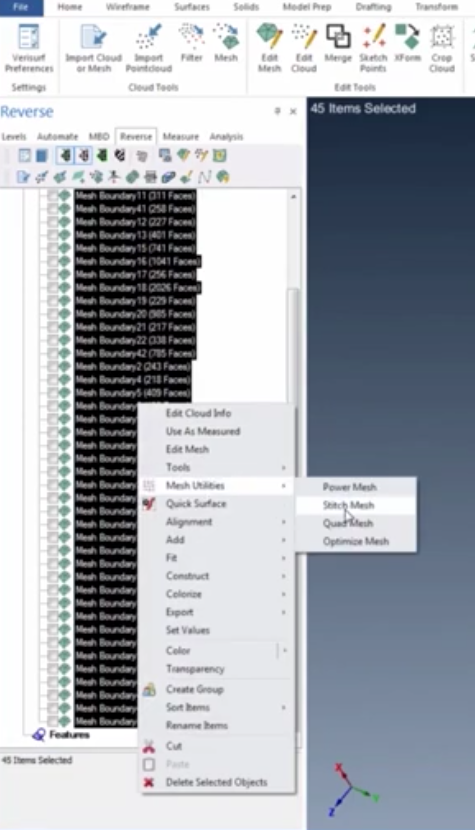

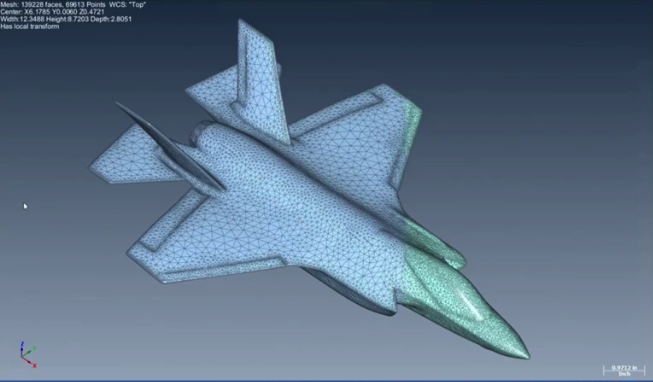

Stitch Mesh connects discontinuous meshes along their common boundaries while maintaining the original mesh definitions. It creates a single water-tight mesh from meshes that were imported from individual CAD surfaces.

With Stitch, you can also reassemble portions of a larger mesh that were separated during editing and cleanup. The tolerance controls the allowable gap or overlap between adjacent meshes. This works without having to remesh or filter the constituent meshes.

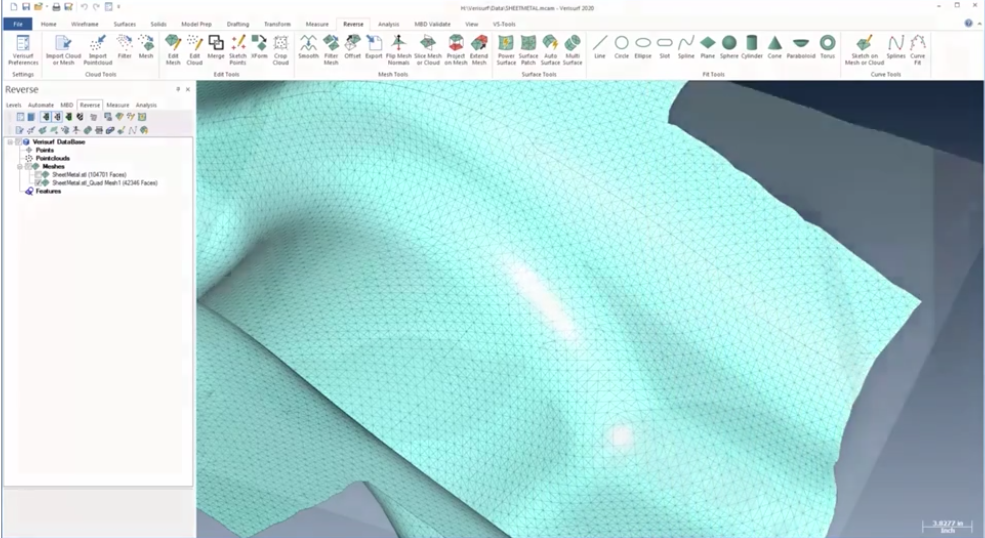

Quad Mesh creates triangles from the quadrilaterals that follow the flow of the mesh curvature. It’s used to improve mesh quality prior to surfacing and to align the mesh with the part edges.

Settings enable control of density and smoothing and allow sharp creases to be maintained. Even random unstructured scans from a hard probe can be made uniform to improve surfacing.

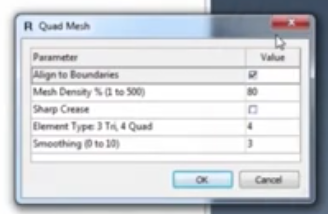

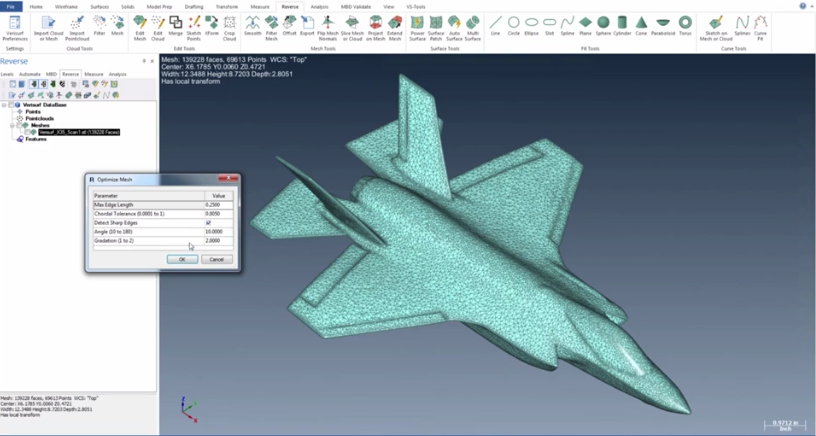

Optimize Mesh reduces the overall size of the mesh while maintaining accuracy by adjusting mesh density based on curvature. Sharp edges can be maintained by specifying the break angle.

And the rate of change in triangle size between areas of low and high curvature can be controlled. Optimize Mesh is a good final step, prior to the use of Quick Surface.

As you can see, the Verisurf Mesh utilities enable programmers to create high-quality meshes from 3D scan data. Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment