This post will explore 3D printing for mold making using Formlabs 3D printers. Mold making with desktop 3D printing allows engineers to expand their prototyping toolkit. It opens up a world of production materials, offering the ability to make short-run batches and to test designs before larger-scale production. Three types of molding strategies can be applied with Formlabs. These include injection molding, thermoforming, and casting elastomers.

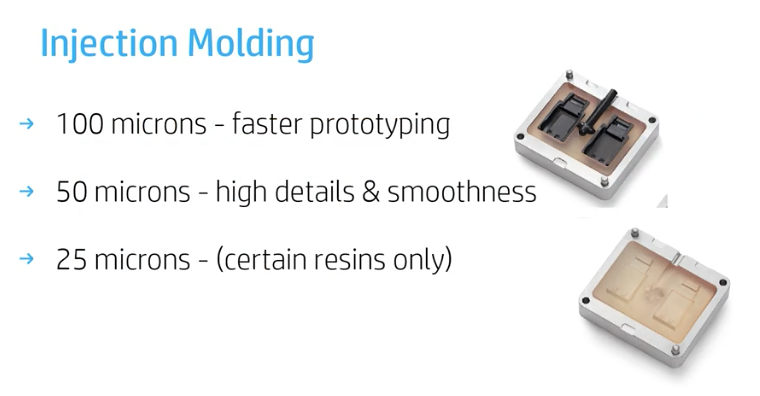

The Form 3 can print inexpensive injection molds to validate and improve designs before metal tooling. They can be printed at both 100 microns for speed or 50 microns for high detail and smoothness.

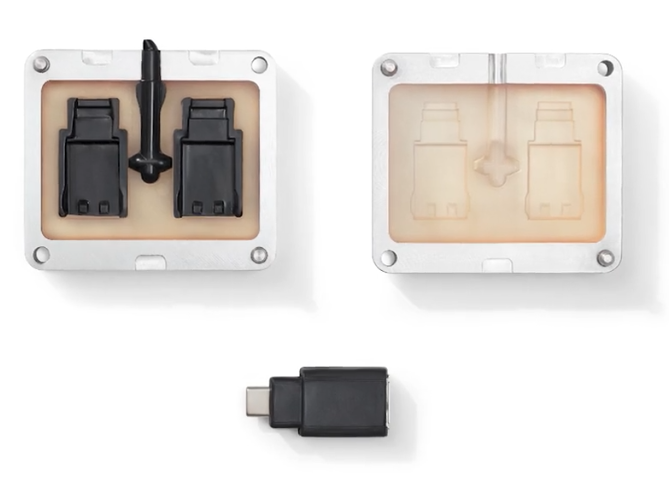

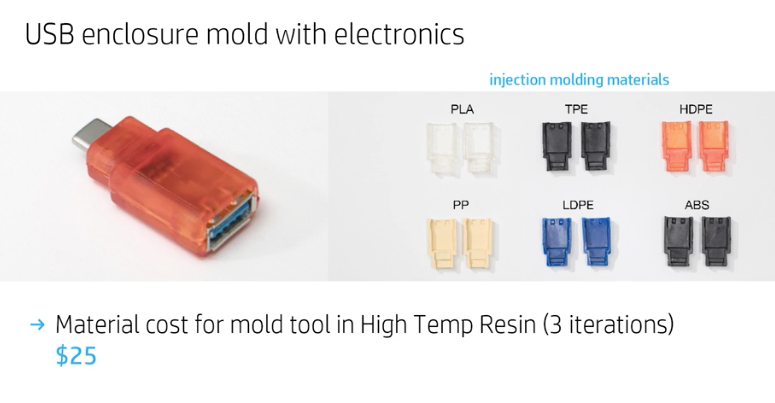

In this example, the newer High Temp resin was used to print an enclosure for a USB device. High temp resin eliminates the thermal shock or deformation found with lower temp materials. The beauty of this example is that the team was able to create three iterations, helping them to remove sink marks, air taps, and correct part shrinkage.

Thermoforming is common for packaging, orthodontic retainers, and food-safe molds. The dies experience less pressure than injection molds, but High Temp is still the best choice. Standard resins can still be used for lower temperature plastics like vinyl.

In this case study, a thin sheet of polycarbonate was thermoformed over a High Temp Resin Die. The surface temperature of the die increases with multiple cycles, so cooling channels can be incorporated to draw out heat.

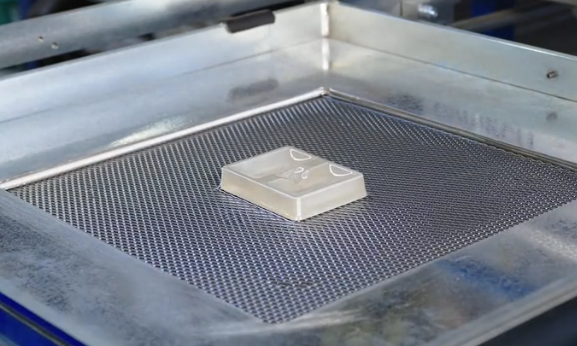

For making molds for Elastomers like silicone and urethane rubbers, Clear Resin allows the material to be observed during the pouring process. These flexible materials can be easily removed and applications range from modelmaking to functional over molds.

In this case study, RightHand Robotics used the Formlabs SLA platform to produce short-run production molds that are used to make urethane joints on a gripper. This outer urethane layer gives the gripper enhanced tactile sensitivity as well as sealing sensor electronics.

As you can see, Moldmaking with Formlabs enables engineers to make short-run production parts and prototypes that look and function like the final product. For more information on the Formlabs Form 3 3D printer, please click the button below.

Leave A Comment