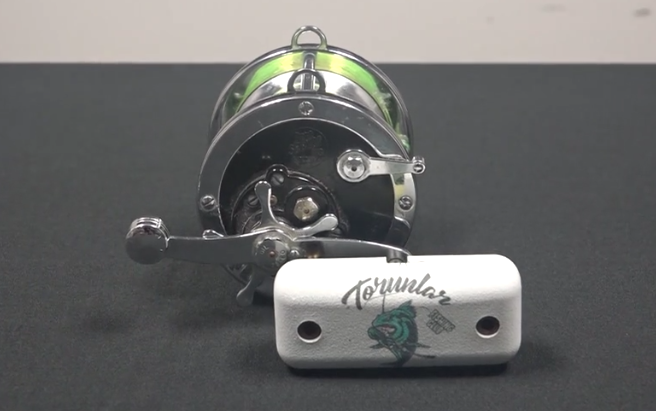

Let’s take a look at how reverse engineering can be used to improve ergonomics in product design. There are times when you may have the need to improve a design, but the legacy files are not available. In this case, your best option is to scan the old part and reverse engineer the CAD file. Once you have a feature-based CAD file, you can make any edits and improvements needed. That is exactly what our application engineer, Hayati Dirim, did after fighting for 45 minutes with a 70lb tuna on a recent fishing trip. He found the handle of his PENN Senator reel to be too small and difficult to work with, due to an uncomfortable grip. Rather than buying a new reel, he decided to reverse engineer it to improve the design.

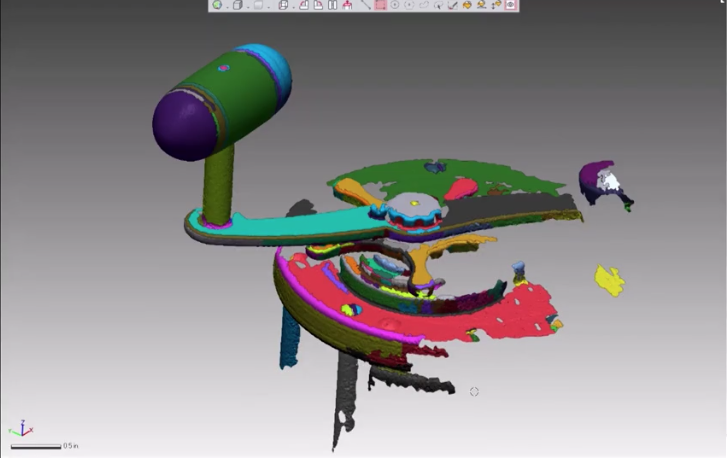

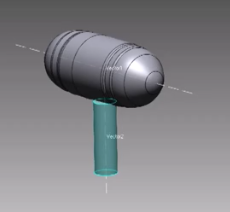

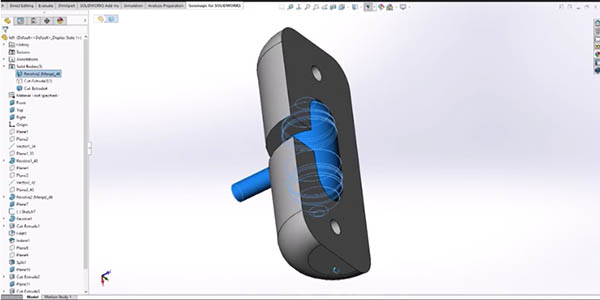

He first scanned the handle portion with a Freescan X7 and cleaned up the Mesh file. Then he used Design X to create a NURBS model of the actual handle and used that geometry to design a new handle on top of it.

The idea was to have the handle snap over the existing design and secure it with quarter 20 heat-set inserts.

Lastly, he 3D printed a prototype on our HP 580 to test for look and feel. He continued this iterative process so as to create a smooth curvature on the outside, to fit better with the palm.

He also added a hinge mechanism. This allows for more rotation in the hand when fighting fish.

The final part was clean, sturdy, and ready for the field. HP’s PA 12 material has the strength necessary to withstand the high force conditions. The full-color logo design added in Netfabb was a nice final touch.

As you can see, this method of reverse engineering can be useful for improving the design of all types of parts and products. This not only saves time by using the proper tool for the job, but also substantial outsourcing costs. Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment