Cimquest at the Atlantic Design Show

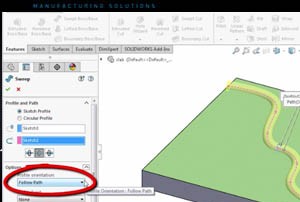

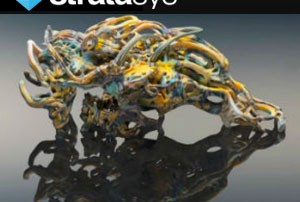

Cimquest recently exhibited at the Atlantic Design & Manufacturing Expo (ADS), which took place at the Jacob Javits Convention Center in New York City. This show delivered the latest innovations in engineering software and 3D printing and Cimquest took the opportunity to display some great new technology. From our 3D printers and scanners to inspection devices and even CAD/CAM, we were able to exhibit the full manufacturing solution. One of the biggest highlights in our [...]