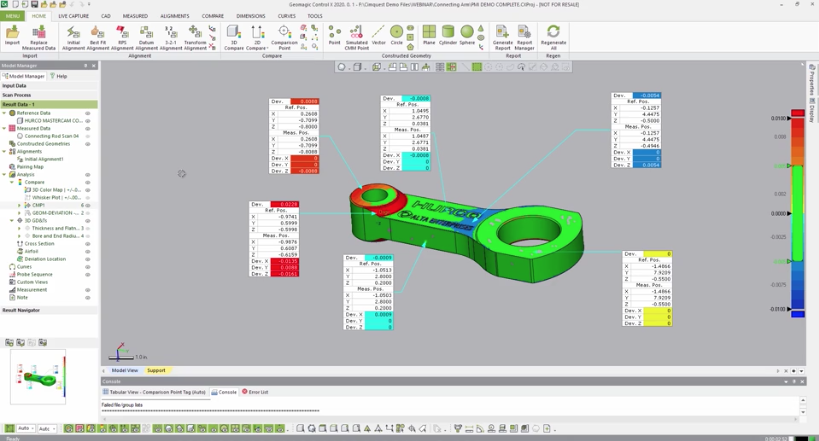

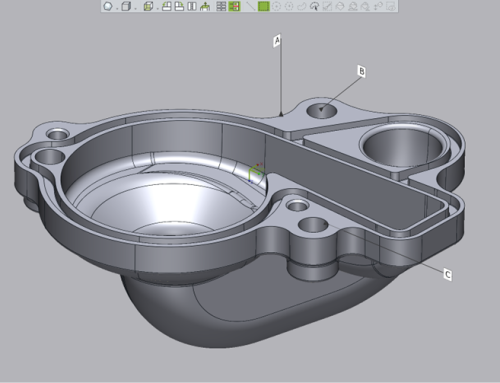

With Control X, you can prepare an inspection routine to process a single scan or point cloud against a nominal CAD model and create whatever inspection criteria you require, including; Color Maps, Whisker Plots, 2D and 3D Dimensions, GD&T callouts, Feature Deviation Comparisons, as well as date and time-stamped inspection reports.

In addition, the 3D inspection criteria consisting of datums, dimensions with tolerances and GD&T can automatically import into Control X from your CAD software as PMI or Product Manufacturing Information.

PMI enables the seamless transfer of dimensional information from CAD into Control X and then the dimensions get automatically evaluated once the scan is aligned to the CAD model. But what happens when you have 10 or 100 or even 1,000 parts to inspect? Would you need to run through the process that many times?

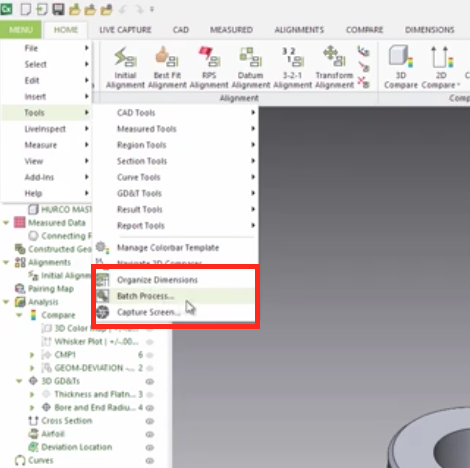

Batch Processing in Control X takes care of that. It enables you to setup a set of conditions and then run the exact same process numerous times. So, if there are 1,000 parts to be inspected, there would be 1,000 scans. They could reside in the same or different folders and you would proceed with the following process.

First, have the initial file open. That being the CAD model, the very first scan and all of the inspection criteria should be defined. Then, open the Batch Processing Menu.

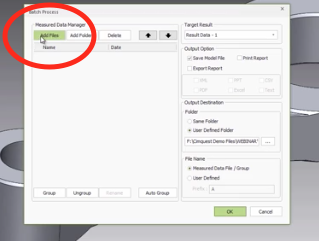

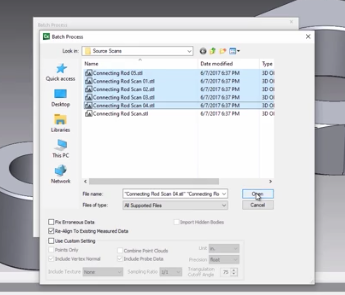

Add Files is your first selection.

Here is where you will want to add all of the polygonal files or point clouds to be inspected. In our case, we inspected five additional parts using the STL format.

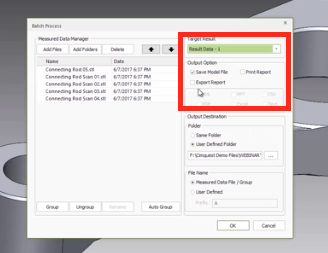

Now, let’s look at the Target Results. Control X allows you to have multiple results files, using different inspection criteria. In this case, we have just one set of inspection criteria to use.

There are three output options: to export the new inspection model file(s), to print the reports, as well as to export the reports. For reporting, you also can choose the report format. For output destination, choose where to place the newly created inspection reports. You can either have the reports maintain the same naming convention they had as scans, or you can provide a new Prefix, ‘Part A,’ for example. Then when the system exports the new inspection files, they would be named; PartA-1, PartA-2 and so on.

Control X is developed by 3D Systems, a premier developer of scan-based reverse engineering and inspection software. The CAD file formats that may be imported are numerous including native files for the most popular CAD systems; Solidworks, Pro-e/Creo, Inventor, Solid Edge and NX. For other CAD products, Control X can import neutral and kernel files such as Step, Parasolids and ACIS.

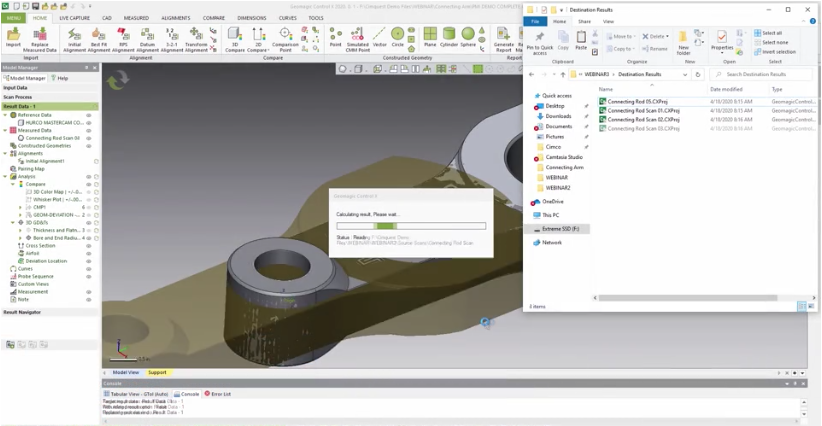

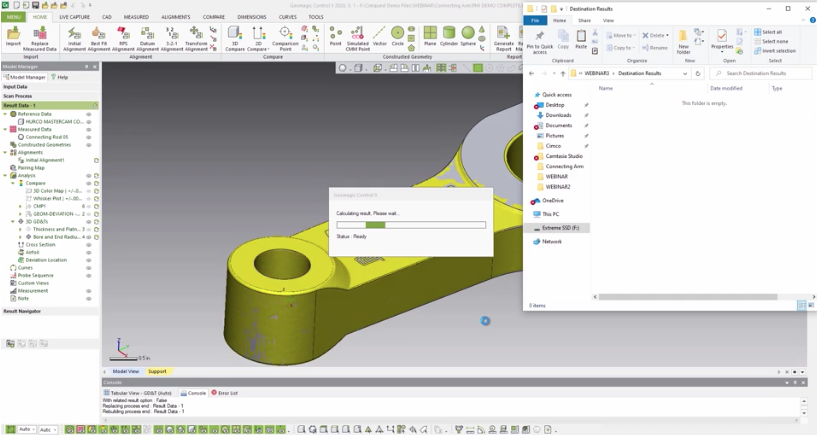

The inspection process runs with no user input in the background and in the illustration above, the Folder view is turned so you can see that the five new inspection reports that get created on-the-fly.

Even if you had 1,000 parts to inspect, all 1,000 scans may be selected as your source files and this process may run overnight. When you come in, in the morning, you will have 1,000 new completed inspection models and if switched on, with 1,000 date and time-stamped reports as well in your desired format.

For more information on Control X, please click the button below.

Leave A Comment