Choosing the Right Type of 3D Scanning Device

When evaluating choices for the appropriate 3D scanning device(s) there are a number of considerations that can lead you to select the best scanning system for your needs. And unfortunately, there may be a necessity to compromise and decide which option is the best choice albeit not perfect in all aspects of the job. Accuracy requirements Size of the workpiece Access to features, such as those obscured from line-of-sight Surface finish – rough or smooth, light or dark color, shiny or matte finish Surface softness or vulnerability Other factors Again, 3D scanning devices will be chosen based on the best but not perfect choice, or availability may be the deciding factor. The options vary widely in terms of the cost of equipment. For non-contact scanners versus tactile CMM-type devices, it should be noted that for soft parts and for those with highly undulated or rough surfaces, non-contact is the only way to go. For tight tolerances, contact CMM devices are best. Articulating Arm & Scanner Combo This solution has the advantage of non-contact, high volume data acquisition of the scanner and also the ability to probe holes into the part beyond reasonable access of the scanner. The probe typically is more accurate than [...]

What’s new in Geomagic Control X 2024.2

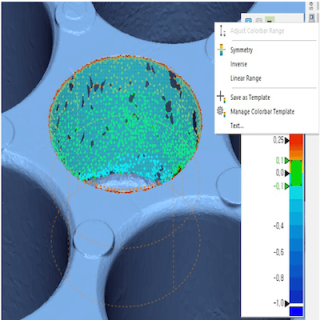

The latest edition of the Geomagic Control X 3D scan-based inspection software is here! This latest release, Geomagic Control X 2024.2.0, offers much to be excited about. Below you’ll find some of the highlights, but remember to check the release note for a full list of updates. Important notice about plug-ins The following plug-ins have been removed from the list of built-in plug-ins: Geomagic Capture AICON Konica Minolta VIVID Konica Minolta RANGE5/RANGE7 You can find the instructions on using these hardware plug-ins for scanning here and the instructions for PMT Probe Plug-Ins here. Replace Reference Data Improvements The following improvements have been made to the Replace Reference Data to enhance your productivity: Visualization of Associated Inspection Features in the Model Manager Tree A new “Center Tree and Zoom Object” option has been introduced in the Replace Reference Data command. This option expands the Model Manager Tree, and highlights and centers associated inspection features in the Tree when assigning faces or edges to those in the new Reference Data. This enhancement improves visualization and enables a clearer understanding of the impact of reassigning replaced entities. Replace Reference Data in the Context Menu of the Model Manager Tree You can now access the Replace Reference [...]

3D Scanning vs Probing

Why is 3D scanning often preferred for reverse engineering, and how does it compare to contact probing methods? There are pros for non-contact scanning and there are pros for tactile probing methods, but for many parts scanning works better or is essential. Following is a look at the benefits of 3D scan to CAD, and what might be better suited to probing. A hybrid of both techniques may be the best approach at times. Pros for scanning: 3D scanning makes it easy to obtain 100 percent coverage including fine detail, critical for formed sheet metal panels. While simple geometric features like planes, holes, and flats can be measured with hand tools such as calipers, micrometers, and height gages, shapes that are non-geometric, complex contours (for example, an aircraft airfoil or an automotive body panel) cannot easily be reverse-engineered with gages. Soft, non-rigid parts are not suitable for contact probing since they deflect when touched by contact probes or gages. Also, some are delicate, and therefore, it is desirable to use non-contact methods. Super-complex, organic shapes (such as a person or animal intended to be manufactured as a figurine) are almost impossible to reverse engineer using contact probes or gages. Scanning gathers a lot [...]

Mastercam 2025 Quick Reference Card

Mastercam 2025 was recently released and we hope you are enjoying some of the enhancements. There are many new features in the software to make you more efficient. Click the button below to download an additional tool to boost your productivity – the Mastercam 2025 Quick Reference Card. This handy desktop reference can save you lots of time by referencing keyboard shortcuts to get to all the most commonly used Mastercam functions. Download Here

Digital Manufacturing Tools Are Enabling Growth in Patient-specific Design

There are significant advantages to using patient-specific medical devices, from improving patient outcomes1 to lowering healthcare costs2. But for a long time, expensive and complicated production processes presented a major obstacle to the wider adoption of this approach. That's changed with the advancement of digital manufacturing. Novel technologies, such as 3D printing, 3D scanning and software for organic 3D design – to name a few – have taken the efficiency and speed of patient-specific design to a whole new level. Another thing that these diverse technologies have made possible is the consolidation of all stages of the patient-specific design workflow into a streamlined process. The outcome: a rapid rise of patient-specific design. In this article, we dive into this burgeoning area. We examine the digital tools that play a central role in patient-specific design, their place in the workflows, and developments on the horizon. 1. Data collection With respect to patient-specific design, data collection refers to acquiring data about the patient’s anatomy or physiology through medical imaging and 3D scanning. Medical Imaging Medical image segmentation is essential for creating the accurate 3D models that allow physicians to perform surgical planning, create patient-specific product designs, recognize complex patterns or isolate regions of interest. These [...]

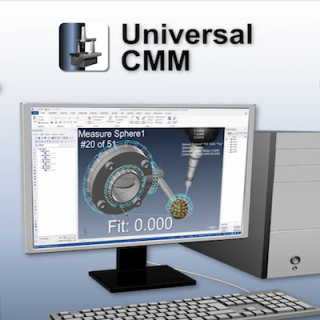

Programming your CMM from within Mastercam

Most CMM’s will ship with a language-based CMM programming software package that is powerful but very time-consuming to learn and challenging to master. It is therefore very common for job shops and manufacturing facilities to have just a single CMM programmer who has gone through the painstaking efforts of becoming proficient with the software. But what happens when that person goes on vacation, is out sick, or leaves the company? Many shops own very expensive CMM’s that are either very underutilized due to the challenges associated with CMM programming or worse, are sitting completely idle. Introducing the Universal CMM (UCMM) from Verisurf Corporation The UCMM enables any CMM to be programmed and run from within the Mastercam Design environment, thereby opening the doors to convert any Mastercam CNC Programmer into a CMM programmer in no time at all! All of the CMM’s functionality is fully supported through the UCMM, including; probe calibrations, multiple part alignment techniques, Indexing heads, probe changers, joysticks, tactile scanning, and more. The UCMM is also a ‘codeless’ CMM programming system. Therefore all programming and execution of a CMM program takes place from within the graphical Mastercam environment. Post Processors, as required for CNC programming, are not needed for CMM [...]