3D Printing End of Arm Tools

Robotic arms carry out a wide range of functions in this modern age of manufacturing. With FDM technology, companies can now produce custom end of arm tools tailored to sophisticated applications and processes, at a fraction of the cost. Robotic arms carry out a comprehensive range of tasks, including material handling, sorting, palletizing, transporting, and even inspecting or machining. The EAOT of a robot is the key piece, which interacts with an object, for example through gripping or welding. While some arms are generic in design, many processes require customized arms to engage unique objects with complex features. Custom EOATs tend to be machined from metal due to their low volume nature. However the extensive programming times and costs to machine custom arms can deter companies from investing in them. Companies may instead be compelled to settle for stock solutions, which are limited in their ability to manipulate complex objects. FDM technology can produce custom EOAT’s tailored to sophisticated applications and processes. Thermoplastic arms printed directly from 3D CAD files are lighter than metal, allowing for faster movement, increased motor efficiency and a reduction in component wear. They are also durable yet they won’t scratch the objects they grip. The FDM build process [...]

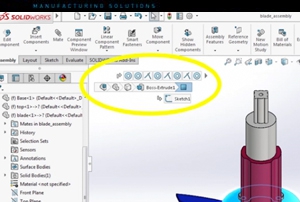

SolidWorks 2016 – Selection Breadcrumb

There is a new feature in the design interface of SolidWorks 2016 called “Selection Breadcrumbs” that will allow you to select a part or feature in the graphics area and then refine that selection through the context-based representation of the item, or the “trail of breadcrumbs” connected to the selection. Take this assembly made up of 4 mated parts. When you select a face, you can see all of the mates of the component that face belongs to in the breadcrumbs pop-out. In previous versions of SolidWorks, to view the mates you either had to right-click the component or find the component in the FeatureManager design tree and open the mates folder. Now, the Breadcrumbs feature provides access to the entire hierarchical chain of entities from the item you selected up through the top level document. You can display the context toolbar and a shortcut menu by right-clicking on a breadcrumb item. Also, you can move Breadcrumbs out of the top left corner and to your pointer location by pressing “D” on your keyboard. Breadcrumbs are available for both parts and assemblies and are enabled by default. You can remove the breadcrumbs from the screen by pressing “Escape” or clicking an open area [...]

New 3D Scanners from Creaform

We have expanded our metrology and reverse-engineering product line to include new 3D scanners from Creaform. The Go!SCAN 3D produces fast and reliable measurements in a portable and compact form. With the ability to capture 3D organic shapes in full color, this white light scanner can be used for a diverse range of applications, assisting engineers throughout each step of the product development process. We also offer the Handy Scan 3D, a handheld laser scanner of new generation. This flagship scanner matches portability with accuracy, providing high resolution scans of mechanical parts at a rate 25 times faster than the previous generation. Creaform Scanners come equipped with VXelements, a fully integrated 3D software which delivers real-time visualization, in a user friendly interface. Enhancements such as hole filling and surface optimization deliver exceptional control over the scanning experience. If you desire versatility, speed, and ease of use, then Creaform Scanners are the optimal solution for your metrology and reverse-engineering needs! In addition, both the Handy-SCAN and Go!SCAN handheld scanners fully integrate with our flagship reverse-engineering and metrology software products, thus allowing Cimquest to offer more diverse solutions for 3D Scanning coupled with complete compatibility to our existing software products. To learn more, call us [...]

Stratasys Medical Applications Reshape Patient Care

3D Printing: Revolutionizing Surgery and Improving Outcomes If 3D Printing has only one advantage it is the ability to produce complex, organic shapes. However usually one material is used and as you may have noticed, we don't exactly feel like Lego's, the stuff of most printers. Imagine being able to replicate the exact procedure of transplanting a Kidney or of knowing EXACTLY how a face transplant will be connected because you already tried it out before you even got in the operating room. This has simply been impossible up until now. Traditional Medical Models are one size fits all. Humans are not. The breakthrough is in being able to print and test patient specific anatomy. The absolute cutting edge of 3d Printing is in producing any shape, and now, in mimicking material properties, including those of tissue and bone. In this video Scott Rader of Stratasys walks us through just a few ways Stratasys Connex printers have been able to cut time in surgery and improve outcomes. For more information on our Stratasys line of 3D printers, please click the button below. More Info

World’s First Jet-Powered, 3D Printed UAV Tops 150 MPH with Lightweight Stratasys Materials

Aurora Flight Sciences, a Virginia-based manufacturer specializing in advanced unmanned aerial vehicle (UAV) systems, is pushing the envelope of UAV design by teaming up with Stratasys to create the world’s first jet-powered, 3D printed aircraft. Using 80% 3D printed parts, the UAV is composed of Stratasys’ ULTEM™ 9085 lightweight material to achieve flight speeds of over 150 mph. The high-speed system boasts an impressive 9-foot wingspan and weighs in at only 33 lbs. Dan Campbell, Aerospace Research Engineer at Aurora Flight Sciences, explains how the UAV project met a number of goals using Stratasys 3D printing solutions. Aurora’s UAV demonstrates Stratasys' FDM-based 3D printing solutions ability to build a completely enclosed, hollow structure which, unlike other manufacturing methods, allows large – yet less dense – objects to be produced. “A primary goal for us was to show the aerospace industry just how quickly you can go from designing and building to flying a 3D printed jet-powered aircraft. To the best of our knowledge, this is the largest, fastest, and most complex 3D printed UAV ever produced.” Stratasys 3D printing solutions provided Aurora with unlimited design freedom and the capability to improve upon the design without the constraints of traditional manufacturing. Aurora [...]

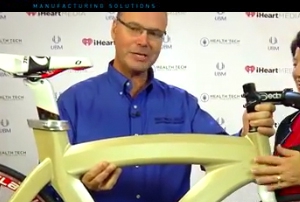

Cimquest on HealthTec Talk Live

Our President & CEO Rob Hassold was interviewed on HealthTech Talk Live at the MD&M Philadelphia Conference 2015, hosted by Jill Schiaparelli. Rob explained some of the latest advancements in manufacturing including efficiencies in traditional subtractive manufacturing, as well as the new materials available for 3D printing. He showed off a bicycle frame that Cimquest designed and 3D printed in-house and explained some of the ways 3D printing is helping in the medical industry. Watch the interview below.