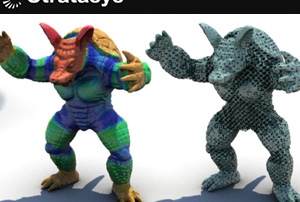

Micro-Structures to Control Elasticity in 3D Printing

Using a new method developed by Disney Research, a 3D-printed teddy bear can have a stiff head, a flexible tummy and bendable arms, even though all of it is made of the same relatively stiff material. By using a printer to alter the small-scale structure of the material, the Disney researchers showed they could vary its elasticity dramatically. They developed families of compatible micro-structures with varying elastic properties, enabling designers to select the properties desired for each region of an object. The team demonstrated their new method to produce several deformable toys. "Many functional objects in our everyday life consist of elastic, deformable material, and the material properties are often inextricably linked to function," said Christian Schumacher. 3D printing usually involves only a single material or a very small set of materials. "However, 3D printing easily produces complex, 3D micro-structures which we can use to create metamaterials with properties beyond those of standard printer materials," Schumacher said. Metamaterials are substances that derive their bulk properties from the shape and arrangement of their micro-structures, rather than the composition of the material itself. What the Disney Research team did was to use a variety of these metamaterials so that different regions within a single object [...]

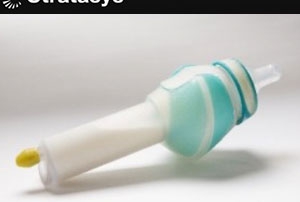

Student 3D Prints Life-changing Baby Bottle for Preemies

Ravid Koriat, a recent graduate of the Bezalel Academy of Arts and Design in Jerusalem, used personal inspiration for her final project in Industrial Design. A conversation with her sister-in-law about the challenges of nursing and pumping “mother’s milk” prompted Koriat to design a new style of feeding system, the FEEDER, specifically for newborns in the neonatal intensive care unit (NICU). To improve the system for breast milk collection, storage and delivery, Koriat developed accurate prototypes using Stratasys’ PolyJet multi-material 3D printing technology. The Stratasys 3D printed components of Koriat’s FEEDER system, appropriate for premature or ill babies who are fed via tube, syringe or bottle. Adapting to the NICU Experience Originally planning a career in fashion design, Koriat decided instead to study industrial design – “designing products that are meant to meet actual needs,” she told the Stratasys Blog in an interview. In the research phase of this project, she spoke with NICU parents, nurses and managers at several Israeli hospitals, including Ichilov, regarded as one of top NICUs in the country. “The NICU is very advanced technologically, and sterility is critical,” she explained in her project case study, “but I have found that there are lots of things that [...]

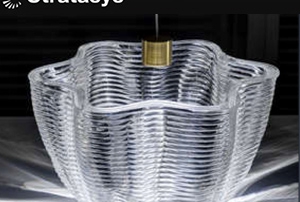

Additively Manufactured Fine Glass

Reposted from http://www.economist.com/ GLASSMAKING began 4,500 years ago, in Mesopotamia. The industry’s first products were trinkets, such as beads and pendants, cast from moulds and carved by hand. But craftsmen quickly worked out how to make more practical stuff, such as jugs, bottles and drinking vessels, by coiling strands of molten glass around a sand or clay core of appropriate shape, which could then be shaken or scraped out after the glass had cooled. Since those early days, many other ways of forming glass have been invented. These range from blowing forcefully through a tube to inflate a hot gob of the stuff, creating a hollow vessel, to floating it as a liquid on a bed of molten tin to produce perfectly flat window panes. But ancient wisdom often still has value, and now a group of researchers at the Massachusetts Institute of Technology have had another look at the coiling method, pronounced it good, and modernized it. Their principal updating is to dispense with the core. Instead, they have turned to the field of 3D printing—or additive manufacturing, to give its formal name. Objects of rare beauty, and possibly of great utility, result. Neri Oxman and Peter Houk, the team’s leaders, started with the [...]

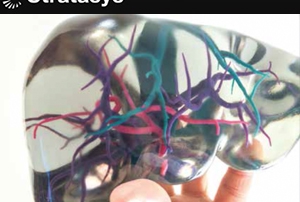

Multi-material Color 3D Printing

“The multi-color and multi-material bio-models assist surgeons to uncover hidden tissues and blood vessels that may be blocked by larger organs in the 2D scans.” — Dr. Maki Sugimoto, associate professor at Kobe University Graduate School of Medicine This 3D printed liver model makes teaching students about blood flow easier. Multi-material color 3D printing enables bio-texture modeling of internal organs. Kobe University Graduate School of Medicine offers top-notch medical training at the Kobe University Hospital in Japan’s Kansai region and also focuses on integrating advanced technologies and innovative applications for medical research and development. Since 2011, Dr. Maki Sugimoto, associate professor at Kobe’s Graduate School of Medicine, has incorporated PolyJet™ multi-material 3D printing technology into medical training and surgery preparation. In 2014, the medical school decided to further realize the potential the technology offers by adding an Objet®500 Connex3™ color multi-material 3D printer to its facility. A New Medical Approach Traditionally, surgeons plan operations based on the CT and MRI images of patients’ conditions. While these images can illustrate a patient’s organ from different angles, they might not show all injuries that could cause possible complications. The Objet500 Connex3 solves this problem: Sugimoto 3D prints full-sized models of patients’ internal organs. [...]

25 Years and Still Counting…Thank you!

25 Years.....where did the time go? Getting really excited for our big Open House on Oct 14th from noon to 6pm! We are hoping to see a lot of our long term customers as well as our new customers that we have had the pleasure to partner with over the years. The event is going to offer 16 different seminars in four different seminar rooms. If you haven't had the opportunity to see the NorthEast's largest 3D Printer Showroom in action this event will be a great opportunity. Some of our customers will be showcasing their products that have been designed and manufactured with the help of our products and support. Let us know if you want to participate in the customer showcase. With hundreds of customers, vendors, employees already registered this very well could be the industry networking event of the year! We hope to see as many of you join us to reflect on 25 years of partnerships as well as discuss the new age of technology heading our way. You can register on-line at http://info.cimquest-inc.com/25th-anniversary-nj Hope to see you all soon!

Surgeons 3D Print Models of Children’s Brains

Reprint from 3dprint.com While most of us have either been the patient undergoing a surgical procedure or a loved one waiting and worrying, few of us have had to be on the other side as the trained surgeon, who often bears the responsibility of performing numerous delicate procedures with lives in his hands on a daily basis. Many of us are thrilled to hear about the innovations 3D printing offers to the medical world as people are saved with progressive implants and devices and quality of life is improved. 3D models are becoming more and more common not only for educating the patient on what is happening, but also for guiding surgeons in diagnosis as well as in treatment and the surgical process. Certain procedures may be completely new for a surgeon and while the 3D model is what he uses to study and practice on, it is probably the same 3D printed model that goes into the operating room with him and potentially shaves hours off the procedure, as well as plenty of stress. Vein of Galen malformation displayed in 3D model [Credit: Boston Children’s Hospital] Recently, at Boston Children’s Hospital, surgeons were looking toward several tricky pediatric procedures. Thanks to [...]