How To Finish a 3D Printed Part To Look Like a Production Part

By Jason Matses on July 31, 2015 Finishing and painting 3D printed parts is easy and can be done following these few steps. Painting and finishing can transform your 3D prints into highly aesthetic parts, giving them appearance of production parts. Prototypes, concept models, and end-use parts can all be finished to presentation-quality in the matter of hours. The four main steps we will cover here are: Preparation, Sanding, Priming, and Painting. 3D printed bike part with support material. This part was printed in ABS-M30 plastic at 0.010” Layer resolution on a Fortus 250mc printer. It is fresh off the printer so it still has support material on it (which is white). Prepare Remove support material, either by hand or dissolve it away if necessary. Rinse part thoroughly in warm water. Cleaned part, all support material removed. Sand Sand the areas of the part that will be painted. Start with a rough grit like 150 or 220 grit sandpaper. Once most of the layer lines have been smoothed out move to a 300 to 400 grit sandpaper. Keep in mind starting off with a part printed at 0.007” or 0.005” layer resolution will be a smoother part requiring less [...]

3D Printed Patterns Reduce Costs and Improve Production Agility

Learn how to reduce costs and improve production agility for silicone molds with 3D printed pattern. Silicone molding is a manufacturing process for parts used in prototyping, functional testing and short-run production. Obtaining good results out of the mold requires the use of strong, accurate mold patterns. These patterns are typically machined from metal or wood, but the process is usually time-consuming and expensive. An FDM 3D printed pattern (white) used to make a silicone mold and resulting parts for an MRI coil cover. Stratasys’ FDM-based (Fused Deposition Modelling) additive manufacturing solutions offer a better and more agile alternative for producing patterns for silicone molding. FDM 3D printed patterns are strong and won’t distort under molding pressure or break when they’re removed from the mold. They’re dimensionally stable too and can be used to produce numerous molds with accuracy. The best part of the story, however, is that FDM 3D printed patterns are usually significantly less expensive. Contact us today to learn more about 3D printing.

Executives At Stratasys Learn About Additive Manufacturing in Key Industries

SME’s The Big M Conference returned to America’s manufacturing hub - Detroit, Michigan - for a two-day event illustrating the future of manufacturing. The conference gave industry leaders the opportunity to explore emerging technologies and innovations that are needed to create better solutions for businesses. Stratasys networking breakfast attendees experienced the design advantages and durability of 3D printed parts. Stratasys kicked off its participation with a networking breakfast, welcoming more than 20 high-level executives from different manufacturing companies for a discussion on the significance of additive manufacturing integration in today’s industrial segments. Attendees included some of the industry’s biggest players: plastic fabrication manufacturer, Midwest Rubber Company; induction heating and melting equipment manufacturer, Ajax TOCCO; and automotive and defense manufacturer, Precision Global Systems. Stratasys Midwest territory manager and networking breakfast presenter, Paul Carlson, noted that growth of applications in aerospace, automotive, healthcare, and other industrial verticals could eventually support a +$40 billion market over the next 15-20 years. Joe Gibbs Racing design engineer, Brian Levy, also presented at the breakfast. As one of the leading NASCAR racing teams, Joe Gibbs Racing is no stranger to success both on and off the track. Levy‘s team, a Stratasys automotive customer, has been involved with [...]

Getting a Handle on Stone Age Tools with Stratasys 3D Printing

Stone-age hand-axes were a functional utility tool as well as prehistoric status symbol, demonstrating primeval man’s ability to adapt, innovate and use technology to improve his lifestyle and long-term existence. Among the stone-age community dating back to the Paleolithic Period some 700,000 years ago, hand axes were a sign of success, extraordinary skill and man’s ability to provide for his family. ‘Stone hand-axe’ number 6: Bringing together technologies from the farthest ends of human tool-making. Photo credit: Moti Fishbain In celebration of this historical milestone, these stone-age tools have received a contemporary 3D printing upgrade. In a collection entitled ‘MAN MADE’, designers Dov Ganchrow and Ami Drach have recreated a series of nine stone-age tools, in collaboration with leading 3D printer manufacturer, Stratasys. ‘Stone hand-axe’ number 5; Custom, ergonomic axe handle 3D printed in Stratasys VeroGray material. Photo credit: Moti Fishbain The MAN MADE series of hand-axes includes flint stones formed using the primeval method of knapping – the art of striking flint with another stone to create a new form. In the stone-age, this production technique was absolutely ‘cutting edge,’ requiring remarkable expertise and enabling primeval humans to learn life-changing new skills: the ability to cut meat, scrape [...]

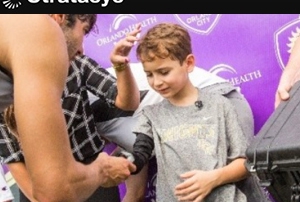

6-Year Old Boy Gets 3D Printed Bionic Hand

Brazilian Soccer Star Kaká Gives 6-Year Old Boy Bionic Hand Created by Limbitless Using Stratasys 3D Printer. Kids pursuing their passions provide terrific inspiration for the team at Limbitless Solutions. Working out of a lab at the University of Central Florida (UCF), Limbitless Solutions creates individualized 3D printed bionic limbs for children that match both their anatomy and personality. These fantastic and personalized devices are produced in just hours on a Stratasys Dimension Elite 3D Printer. Kaká, the Brazilian captain of the Orlando City Lions, helps six-year-old Paulo Costa Boa Nova put on his Limbitless 3D printed hand, produced on a Stratasys 3D Printer. Photo courtesy Orlando City Soccer Club. What’s the Goal? Last week, a young Brazilian soccer fan was the lucky recipient of a 3D printed hand from Limbitless Solutions. Paulo Costa Boa Nova, age 6, has a genetic condition that affected his right arm and hand. Paulo was selected from hundreds of applicants to have his bionic hand built by Limbitless Solutions. Paulo’s dad, Claudio, heard about 3D printed prosthetics from a friend who sent him the link to Limbitless Solutions -- prior to that, these kinds of devices weren’t a practical option for the family. The Stratasys [...]

The Far-Flung Future of Wearables

Repost from www.fastcodesign.com Fitness trackers, email-alert rings, bracelets that tell you how much sun you've gotten: your average wearable is good at conveying information and not much more. But in the hands of Neri Oxman, an architect and founder of the Mediated Matter research group at Massachusetts Institute of Technology, wearables aren't just passive lifestyle devices; they could generate the food, energy, light, and oxygen to keep us alive. In a series of concept wearables that augment human biological systems, Oxman implants synthetically engineered microorganisms in custom-designed vessels. Worn externally, these devices—collectively known as the Wanderers: An Astrobiological Exploration—create the resources that an interplanetary traveler would need to survive in other climates. "Our goal was to design wearables that could have a symbiotic relationship with the human body," Oxman says. There are four devices, and they're modeled after the digestive, nervous, skeletal, and integumentary (hair and skin) systems. Each offers the biological counterpart to the classic life-sustaining elements of earth, water, air, and fire, with different microorganisms implanted in the device’s 3-D printed vasculature. Jonathan Williams/Paula Aguiler/courtesy of Mediated Matter Take Mushtari, a 33-foot-long, corset-like wearable based on the gastrointestinal tract. Created from acrylic resin, it features channels of different widths and opacities [...]