Lamborghini Accelerates and Perfects Automotive Engineering with Stratasys 3D Printed Prototypes and Track-Ready Parts

(This article is a repost from the Statasys corporate blog.) Lamborghini’s 50 year heritage has seen the brand become synonymous with extreme and uncompromising automotive design. With a 50 year heritage that has seen its brand become synonymous with extreme and uncompromising automotive design, Lamborghini relies upon the most cutting edge technologies to uphold its reputation for automotive excellence. Meeting this objective is aided by the company’s continued use of Stratasys FDM-based 3D printing technology, which Lamborghini employs throughout the entire lifecycle of its parts, from rapid prototyping applications to direct digital manufacturing of end-use parts. As you’re about to see, Stratasys additive manufacturing brings several major advantages to automotive engineering including greater design freedom since manufacturing is performed in a digital environment, the accelerated development of functional prototype parts, the ability to produce durable, heat-resistant parts using thermoplastics, and overall faster responsiveness to market demands. Tough Parts with Complex Geometries Delivered in Record Time According to Fabio Serrazanetti of Lamborghini’s car body technical department, the requirement to produce high-strength end-use parts, tough enough to endure the rigors of high-speed racing, as well as the need to create complex geometries in a very tight timeframe, led the company’s engineers to explore [...]

How 3D Printing Customized Jigs and Fixtures Saves Rutland $60,000 Per Year

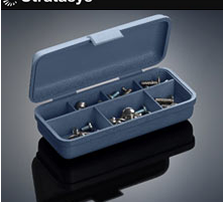

5 Jan. 2015 by Stratasys Staff Rutland Plastics is a custom injection molding company located in Rutland, United Kingdom that produces products for a wide range of companies and industries. Because each project is unique, Rutland must create complementary jigs and fixtures to position and hold the project’s components during manufacturing operations like assembly, gluing, drilling, and measuring. Now thanks to Stratasys 3D printing, creating a steady stream of assembly tools 100% customized for each job, in practically no time, is the new reality at Rutland. Method Annual Production Time Cost CNC 300 days $150,000 PolyJet 100 days $90,000 Savings 66% 40% Why Conventional Wasn’t Cutting It The jigs and fixtures at Rutland are crucial because they streamline the production process, help employees become more efficient, and ensure consistency of the final product. However, as the company grew, creating the jigs and fixtures using conventional methods became a costly burden. Rutland traditionally made approximately 100 new jigs and fixtures annually from aluminum on its CNC milling machines. This process cost $1,500 per piece or $150,000 per year. But the true cost to the company was far greater. Each new jig and fixture also took 3 days to create. This meant that the [...]

Stratasys Material News

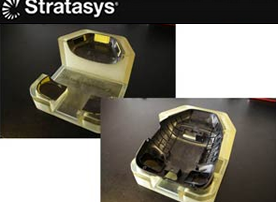

Endur – Now Available in 20 Different Digital Materials! Info from Stratasys February newsletter Endur (RGD450), the advanced PolyJet material for simulating Polypropylene is now available in 20 Digital Material combinations. Endur can now be blended with TangoBlackPlus and TangoPlus rubber-like material to produce 8 new Digital Materials which provide impressive impact strength for tough prototypes and12 new flexible Digital Materials with a range of Shore A values. The Endur material, renowned for its durability and beautiful surface finish, is ideal for creating tough prototypes for snap-fit components, living hinges and other demanding applications. With the new Digital Material options you can now create: Tough prototypes with thin walls and living hinges for consumer goods and electronics product design, Prototypes that mimic polypropylene and over- molding in the same build, Tough, durable and aesthetic prototypes in a range of gray shades and differing flexibly. Earphone case featuring snap-fit lid and rubber-like over-molding. 3D Printed as a single piece using PolyJet Endur and TangoBlackPlus Digital Material combinations. Outer shell – RGD 4830; Inner rubber overmolding – FLX4870 shore70; Stratasys logo on lid – FLX4895 shore 95 ASA Takes FDM Thermoplastic to New Heights Designed for use in multiple industries, Stratasys’ new FDM ASA [...]

Stratasys 3D Printing Keeps NASA Satellite On Time and On Budget – FDM Strong Enough for Space

Reposted from Stratasys Blog We're pleased to announce a new frontier in aerospace 3D printing. Stratasys Direct Manufacturing has partnered with NASA’s Jet Propulsion Laboratory (JPL) to 3D print 30 antenna array supports for the FORMOSAT-7 Constellation Observing System for Meteorology, Ionosphere, and Climate (COSMIC-2) satellite mission. Scheduled for launch in 2016, the COSMIC-2 mission marks the first time 3D printed parts will function externally in outer space. The antenna arrays will capture atmospheric and ionospheric data to help improve weather prediction models and advance meteorological research on Earth. In order to keep the project on time and on budget, NASA needed an alternative to machining the parts out of astroquartz, the material traditionally used for antenna arrays. They turned to Stratasys Direct Manufacturing to produce 3D printed parts that could handle the complex array designs and also be strong enough to withstand the environmental demands of outer space. Stratasys Direct Manufacturing built the custom-designed parts using FDM-based Fortus 900mc 3D Production Systems from Stratasys. FDM was the only additive manufacturing process able to meet the project’s strength and load requirements. NASA chose durable ULTEM 9085 material, a thermoplastic that has similar strength to metals like aluminum but weighs much less. “Using FDM [...]

Stronger, More Colorful Prototypes, End Use Parts with New 3D Printing Materials

Reposted from Stratasys Blog 29 Jan. 2015 by Laurie Carr Color ASA Thermoplastics allow you to bypass further painting or finishing steps, saving time and money Endur Digital Materials are ideal for challenging geometries and repetitive testing – produce durable prototypes with thin walls, living hinges, snap-fits and moving or assembled parts Stratasys’ tenacious new 3D printing materials allow you to produce more durable prototypes for repetitive testing and tough, color-matched assembly tools as well as end use parts more efficiently and cost-effectively than traditional manufacturing technologies. Think in Color with FDM’s ASA Thermoplastic Technology The increase in demand for robust applications with UV-resistant capabilities has quickly established ASA as a popular all-purpose material in additive manufacturing. Stratasys is bringingeight new colors to the ASA product line: red, orange, yellow, green, dark blue, white, dark gray, and light gray. Applications ranging from tooling and sporting goods to consumer products and automotive end-use parts stand to benefit from the new vibrant color ASA materials. Engineers and manufacturers now have the ability to create end-use parts, functional prototypes, and jigs and fixtures in a variety of rich colors with strong, durable mechanical properties. Whether a manufacturer is measuring the effectiveness of color characteristics in a [...]

Stratasys Scores with 3D Printed Football!

Re-posted from Stratasys Blog 27 Jan. 2015 by Stephen Burg Stratasys 3D printing and sports have often teamed up with winning results. Kite surfing, snowboarding, skiing, motors sports, fencing - all had their competitive edge sharpened with 3D printing. We even worked with the University of Texas at Dallas to help them improve their sports concussion testing protocol. But this is the first time that we at Stratasys have 3D printed an actual football. It might even be a world first! Produced on the Objet500 Connex3 Color Multi-Material 3D Production System, the Stratasys ball is 3D printed in three materials: Rubber-like (TangoPlus), Rigid Magenta (VeroMagenta), and Rigid Yellow (VeroYellow) in one 3D print job. In order to give the football that authentic feel, we incorporated the texture of a composite football into the design with raised material. It weighs about the same as the weighted warmup balls favored by quarterbacks. Of course, when you 3D print a football you have to go out and test it. Check out the video to see the final score.