Day 4: Nexa3D | Unlocking the Power of Carbon Fiber 3D Printing

Day 4: Nexa3D | Unlocking the Power of Carbon Fiber 3D Printing Replayed from a live webinar held on November 14, 2023 Watch the replay of Cimquest's exclusive webinar series where four industry giants, Formlabs, UltiMaker, Nexa3D and 3DGence, come together to explore the world of carbon fiber 3D printing with their respective technologies. This webinar series is your gateway to understanding the immense potential and possibilities of carbon-fiber-infused materials with different machines and applications.The last webinar in the series will help you learn about Nexa3D's industrial printers and their capabilities with carbon fiber. Founded in 2014, Nexa3D is a team of passionate additive manufacturing practitioners that are committed to digitizing the world’s supply chain sustainably.

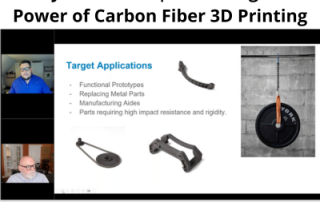

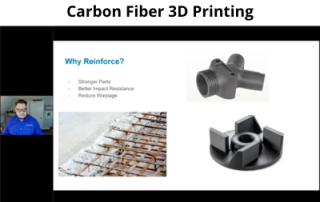

Day 3: UltiMaker | Unlocking the Power of Carbon Fiber 3D Printing

Day 3: UltiMaker | Unlocking the Power of Carbon Fiber 3D Printing Replayed from a live webinar held on November 7, 2023 Watch the replay of Cimquest's exclusive webinar series where four industry giants, Formlabs, UltiMaker, Nexa3D and 3DGence, come together to explore the world of carbon fiber 3D printing with their respective technologies. This webinar series is your gateway to understanding the immense potential and possibilities of carbon-fiber-infused materials with different machines and applications. Discover how UltiMaker is making carbon fiber 3D printing accessible to all. Ultimaker is a Dutch 3D printing company that specializes in the development and production of 3D printers, software, and materials for professional and industrial use. The company was founded in 2011 and has since become a prominent player in the 3D printing industry. UltiMaker offers the widest choice of materials on the market including PET CF, a carbon fiber filament that is used to create high-performance applications, from functional prototypes to manufacturing aids and replacement parts.

Day 2: 3DGence | Unlocking the Power of Carbon Fiber 3D Printing

Day 2: 3DGence | Unlocking the Power of Carbon Fiber 3D Printing Replayed from a live webinar held on November 2, 2023 Watch the replay of Cimquest's exclusive webinar series where four industry giants, Formlabs, UltiMaker, Nexa3D and 3DGence, come together to explore the world of carbon fiber 3D printing with their respective technologies. This webinar series is your gateway to understanding the immense potential and possibilities of carbon-fiber-infused materials with different machines and applications. Explore the high-performance capabilities of 3DGence's industrial-grade printers that print Carbon Fiber. Since 2014, 3DGence has been committed to develop the most versatile, flexible, and cost-effective industrial 3D printing solutions that enable rapid production for our customers. One of those solutions is PC-CF, a polycarbonate material that is reinforced with the carbon fiber, that features a very high strength to weight ratio that allows manufacturers to print parts like never before.

Day 1: Formlabs | Unlocking the Power of Carbon Fiber 3D Printing

Day 1: Formlabs | Unlocking the Power of Carbon Fiber 3D Printing Replayed from a live webinar held on November 1, 2023 Watch the replay of Cimquest's exclusive webinar series where four industry giants, Formlabs, UltiMaker, Nexa3D and 3DGence, come together to explore the world of carbon fiber 3D printing with their respective technologies. This webinar series is your gateway to understanding the immense potential and possibilities of carbon-fiber-infused materials with different machines and applications. First, delve into Formlabs' carbon-fiber-compatible 3D printing system, The Fuse 1+. Formlabs was started in 2011, when three MIT graduate students built the first 3D printer that could achieve industrial, professional part quality at an affordable price. Through continuous commitment to innovation, Formlabs has become the largest supplier of professional stereolithography (SLA) and selective laser sintering (SLS) 3D printers in the world. The Fuse 1+ prints Nylon 11 CF Powder that will enable manufacturers to create strong, lightweight, and heat-resistant parts, without relying on traditional overlay or machining methods. Carbon fiber reinforced parts are used in high-performance industries for applications that require strength, heat-resistance, and stiffness, while remaining lightweight.

Formlabs Fuse Blast – Upgrade Your SLS

Upgrade your SLS Fuse system with the brand new Fuse Blast from Formlabs The brand NEW Fuse Blast seamlessly integrates into the Fuse Series ecosystem and streamlines your post-processing workflow, empowering you to fully clean a whole build chamber of printed parts within 30 minutes and drastically reducing labor time and cost. With the optional Polishing System, Fuse Blast takes your parts to another level by polishing them to a smooth, semi-gloss, and dye-ready surface finish, to deliver consistent, professional-grade results every time. Learn More

Xact Metal 3D Printing Distillery Event – Metal & Mash

Please Join Us for a Special Xact Metal 3D Printing Distillery Event We are thrilled to extend an exclusive invitation to you for an extraordinary Xact Metal 3D printing distillery event that promises to blend the worlds of innovation, craftsmanship, and the art of distillation like never before. Event Details: Event Name: Metal & Mash: Xact Distillery Affair Date: November 16th, 2023 Time: 3:30 PM - 5:00 PM Location: Virago Spirits Distillery, Richmond, VA At "Metal & Mash," we are set to unlock the secrets behind precision metal fabrication while savoring the delights of the Virago Spirits Distillery. What to Expect: Distillery Delights: Immerse your senses in Virago Spirits' artisanal cocktails and discover the craftsmanship that goes into every bottle. Xact Metal Presentation: Dive into the world of cutting-edge technology and explore the limitless possibilities of precision in metal fabrication. Special Guest - Matt White: Join us for an exclusive discussion with Matt White, a distinguished figure in the military and precision engineering field. Matt will share his insights on the invaluable applications of Xact Metal machines in military contexts and beyond. Networking and Interaction: Connect with fellow technology enthusiasts, engineers, innovators, and aficionados in a relaxed and inviting atmosphere. A Flavorful Affair: [...]