3D Printing Provides New Options for Extol

Reprint from Additive Manufacturing Manufacturing technology supplier Extol has always served customers who are producing polymer parts. Now, it's making some of those parts in-house through 3D printing, providing new options ranging from functional prototyping into bridge production and beyond. As the automakers centered in Detroit have been chasing electrification and faster, more agile product development, a manufacturer on the other side of the state of Michigan has felt a shift in the supply chain for polymer parts. In the past, vehicle development was slower, more in line with the lead times expected for injection mold tooling. If new plastic parts couldn’t be sourced in time, automakers often had the option to pull from inventory developed for previous years’ models to get cars into testing and fulfill early purchases. But electric vehicles often don’t have this luxury; whether developed by startups or legacy OEMs, EVs tend to be new vehicle platforms without legacy parts to fall back on — and they are being launched into the market at accelerated rates, creating a demand for faster production. Read the Full Story Here

Bridge Production Is Real Production

Reprint from Additive Manufacturing The chance to launch a product into the world using additive manufacturing as the initial process delivers important new possibilities and even keeps on delivering advantages far into the product’s life. We are watching additive manufacturing find its place as an accepted and established method for making production parts. What will be the ultimate extent of additive’s share of production? One way to think of this is as a percentage: the portion of production performed through 3D printing. However, another way to see AM finding its place is in terms of sequence: the role additive production is finding in the stages of development of manufactured products. Similarly, we are watching additive manufacturing realize new possibilities. One way to see this is in engineered geometries — the elaborate forms, and customized forms, that can only be made through AM. However, another way to see AM realizing new possibilities is in the products that never would have come to market without it, because of the way 3D printing permits both fast speed to market and bringing the product to market without the investment and commitment needed for production tooling. Read the Full Story Here

NASA Sends Formlabs Parts to Space

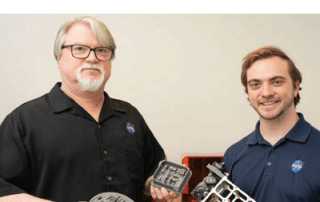

Reprint from Digital Engineering 247 Parts will ride aboard the SpaceX Dragon Resupply Capsule. Later in the summer of 2022, SpaceX will launch its 25th commercial resupply services (CRS-25) mission to the International Space Station (ISS). On board, the cargo capsule will be 4,500 pounds of food and equipment for the crew members on board the ISS. This mission is part of the ongoing cargo contract between SpaceX and NASA and involves collaboration and partnership between the two entities. Among the pieces of equipment on the CRS-25 flight will be electroplated brackets printed on a Form 3 stereolithography (SLA) 3D printer from Formlabs. The brackets are designed to hold a laser during various experiments and will be exposed to the external environment of the space station. NASA engineers display the 3D printed and plated components in front of the Formlabs printers. Image courtesy of NASA’s Goddard Space Flight Center. The 3D printed and plated parts will be exposed to the harsh environment of space and the results could inform how NASA, SpaceX, and possibly other aerospace manufacturers may incorporate additive manufacturing into potential future product plans. NASA engineers at the agency’s Goddard Space Flight Center have been working with the Formlabs [...]

Ultimaker 3D Printing Materials Promotion

From now until the end of October 2022 Ultimaker is running special promotions on their spools of filament. The more you spend, the more you save . . . Spend: Receive: $2,500 Purchase HW + 6 spools of filament and get 50% off the filament. $5,000 Purchase HW + 12 spools of filament and get 50% off the filament $10,000 Purchase HW + 30 spools of filament and get 50% off the filament. $20,000 Purchase HW + 66 spools of filament and get 50% off the filament. You can pick your own filament, or you can choose from the Pre-built filament packs below. Please contact us for more information. Contact Us Today

JawsTec Purchases XYZ Printing SLS Machines for High-Speed Sustainable Part Production

JawsTec, a premier US-based printing service that offers custom rapid manufacturing for every industry, adds four XYZ MfgPro230xS SLS machines to its fleet of MJF, EOS, AMT, Dyemansion, and CNC machines. JawsTec CEO, Oscar Klassen, pointed out that the open platform XYZ SLS machines offer something other SLS manufacturers do not, the ability to use end-of-life powder from EOS and HP MJF, for high-quality printed SLS parts. On top of this, the functional sustainability of the powder, and the smaller build of the 230 allows for JawsTec to run 22-hour full build cycles followed by a 2-hour cooling cycle with zero negative effect on part accuracy, surface quality or the powder. "The adoption of the smaller platform for high daily throughput is a game-changer. We have a 4–5-day turn-around on most printing with options for an expedited 2 business day turn-around on 3D Printing Service, these machines allow us to print more of the expedited jobs for our customers." XYZ Printing Director for the America’s Industrial Printers, John Calhoun makes the point that JawsTec spent 2 months testing the reliability, accuracy, quality of parts, software, and workflow integration. The result of this test made the expansion to 4 units an easy choice. "XYZ [...]

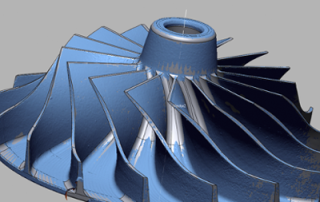

Design X Essentials – New Light Version of Design X

Design X is a remarkable product that enables the creation of a fully-featured CAD model from a scan or point cloud from any device that can produce one of these files. It can return planes, sketches with constraints, dimensions, features, and can generally build completely native, history-based CAD models for a variety of the most common CAD systems including Solidworks, Solid Edge, Inventor, Pro-e, Creo, and NX. Today, the requirements for a fully native CAD model with history are somewhat less important than they were many years ago when most CAD systems were only history-based. CAD systems that were formally history-based now offer “Direct Modeling” tools or have released new versions of the product that support both Direct as well as history-based Modeling. This makes neutral and Kernel file formats such as Step, VDA, Parasolid, and ACIS just as productive for these modelers as history-based models. Introducing Design X Essentials Design X Essentials is half the price of Design X but still includes the vast majority of modeling tools that make Design X such an incredible system. While the transfer of a fully native, history-based model into a product like Solidworks isn’t part of Design X Essentials, it could still create Step or [...]