JawsTec, a premier US-based printing service that offers custom rapid manufacturing for every industry, adds four XYZ MfgPro230xS SLS machines to its fleet of MJF, EOS, AMT, Dyemansion, and CNC machines.

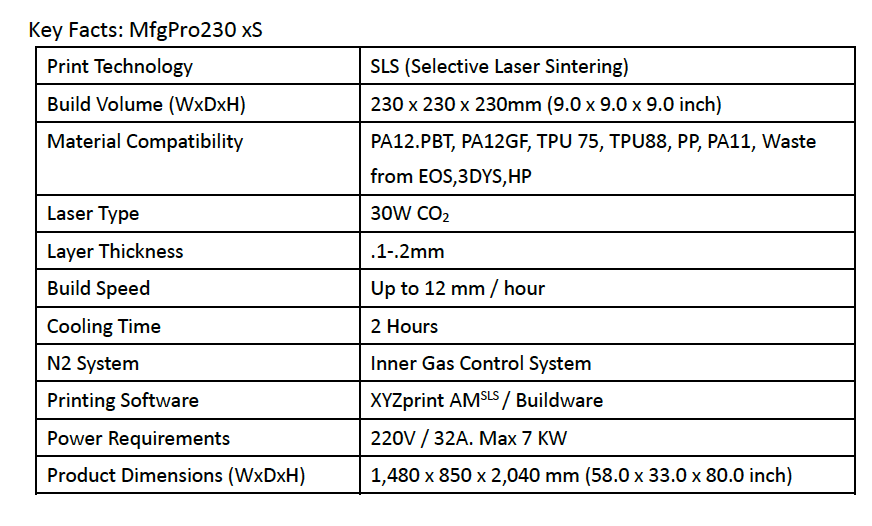

JawsTec CEO, Oscar Klassen, pointed out that the open platform XYZ SLS machines offer something other SLS manufacturers do not, the ability to use end-of-life powder from EOS and HP MJF, for high-quality printed SLS parts. On top of this, the functional sustainability of the powder, and the smaller build of the 230 allows for JawsTec to run 22-hour full build cycles followed by a 2-hour cooling cycle with zero negative effect on part accuracy, surface quality or the powder.

JawsTec CEO, Oscar Klassen, pointed out that the open platform XYZ SLS machines offer something other SLS manufacturers do not, the ability to use end-of-life powder from EOS and HP MJF, for high-quality printed SLS parts. On top of this, the functional sustainability of the powder, and the smaller build of the 230 allows for JawsTec to run 22-hour full build cycles followed by a 2-hour cooling cycle with zero negative effect on part accuracy, surface quality or the powder.

“The adoption of the smaller platform for high daily throughput is a game-changer. We have a 4–5-day turn-around on most printing with options for an expedited 2 business day turn-around on 3D Printing Service, these machines allow us to print more of the expedited jobs for our customers.”

XYZ Printing Director for the America’s Industrial Printers, John Calhoun makes the point that JawsTec spent 2 months testing the reliability, accuracy, quality of parts, software, and workflow integration. The result of this test made the expansion to 4 units an easy choice.

“XYZ Printing offers unprecedented machine satisfaction guarantees and the lowest maintenance costs. Three years of maintenance on the XYZ 230 is under $14k. In fact, the MfgPro 230xS machine cost is nearly equivalent to many of our competitor’s single-year maintenance contracts for production powder bed systems. XYZ SLS technology is the only choice for customers looking for the best in sub 230mm part production speed and reliability while offering advanced materials like AM Polymers PBT and a fully sustainable zero-waste part production solution.”

Click below for more info on XYZ Printing.

Leave A Comment