HP Jet Fusion 3D Printing Shortens Time to Market

Rapid Prototyping In the mad rush to get a new product to market, every hour counts, and as time passes, competition waxes while customers wane. In recent years, technological advances have dramatically accelerated the traditional product manufacturing lifecycle. Innovations in advanced analytics, artificial intelligence, and digitization are enabling companies to get new products to market faster than ever before. To keep up with increasing speed to market and shorter product lifecycles, many companies are turning to 3D printing to stay ahead of the competition. While 3D printing has long been used as a prototyping tool, new advancements have helped increase the speed, helped improved the mechanical properties, and helped lower the cost of the technology. Specifically, with the introduction of HP Jet Fusion 3D Printing, companies are reaping the benefits of rapid prototyping and easier transitions to full production. Ultimately, with HP Multi Jet Fusion technology, customers are embracing a technology that enables them to move at the speed of their ideas. Accelerating design & iteration Innovation requires iteration: Designers can cycle through dozens of ideas before deciding on a final design, making iterations time consuming and expensive. Thankfully, with HP Multi Jet Fusion technology, designers have the freedom to produce multiple prototypes [...]

Investment and Sand Casting Processes Part 1

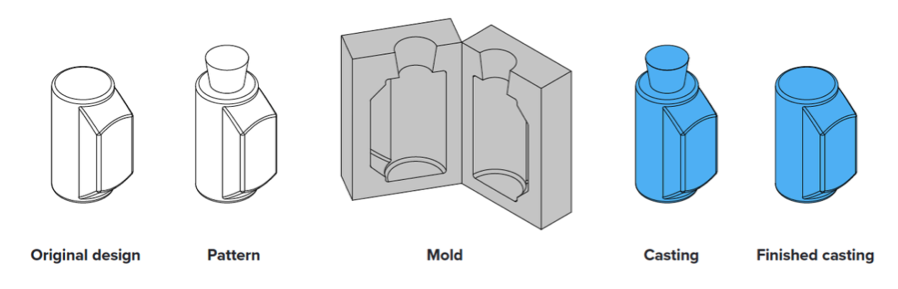

Metal Casting Basics For applications where parts require fine features or complex geometries, casting remains a cost-effective and highly capable manufacturing process, producing critical components for aerospace, automotive, and medical applications. Metal casting dates back to at least 3200 B.C., progressing through many cycles of innovation to become the reliable, modernized process it is now. Today, industrial metal casting processes are used to make everything from knee implants to tractor parts. The basic process to create cast metal parts has a few steps common across different techniques: A manufacturer creates a pattern that represents the part, either as a removable element to make an impression in a material like sand, or left inside of the mold material and subsequently burned or melted out. In either case, a cavity in the shape of the pattern is left behind, and molten metal is poured in. The molten metal cools, and the mold is either opened up or broken apart to retrieve the casting. Cast parts have vestiges of the process where vents, gates, and feeders that direct gases and molten metal during casting. To finish the cast parts, a foundry worker trims away excess material, and files, grinds, machines, or sandblasts parts to achieve final [...]

HP Leads Digital Manufacturing Forward

New HP Jet Fusion 5200 Series 3D printing solution unleashes manufacturing predictability, breakthrough economics, and new applications; Industry leaders BASF, Jaguar Land Rover, Materialise, Siemens, and Vestas lean in with HP; New HP Digital Manufacturing Network for high-quality parts at scale. HP Inc. recently unveiled a series of innovations and partnerships helping its customers accelerate their digital manufacturing journey. HP is expanding its industry-leading 3D printing portfolio with the new Jet Fusion 5200 Series 3D printing solution, an industrial 3D printing system bringing new levels of manufacturing predictability, efficiency, repeatability, and quality to customers scaling to full production. To further enable customers digitally transforming their manufacturing, HP is also expanding its strategic alliances with industrial leaders BASF, Materialise, and Siemens, and launching the HP Digital Manufacturing Network, a new global community of proven, large-scale 3D printed parts providers. “The Fourth Industrial Revolution is one of the most transformative forces in our lifetime. New technology innovations will be required, new partnership models will emerge, and new modes of doing business will unfold,” said Christoph Schell, President of 3D Printing and Digital Manufacturing at HP Inc. “HP is committed to helping customers with diverse manufacturing needs turn change into opportunity by delivering the most innovative [...]

Introducing the New Form 3 from Formlabs

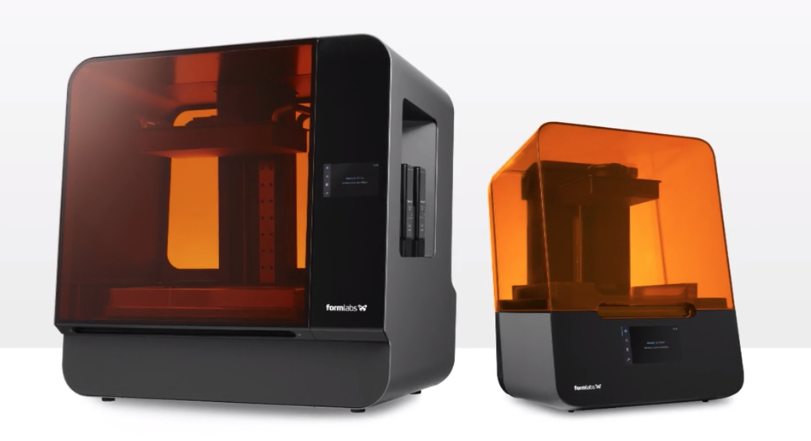

This article will provide an overview of next generation of Formlabs 3D Printers – the new Form 3 and Form3L from Formlabs. The Form 2 took the 3D printing industry by storm, giving engineers access to industrial quality SLA in a desktop machine. Building on the success of this platform, the Form 3 brings even greater detail and speed for engineering teams. The Form 3 is powered by a new technology called Low Force Stereolithography. The process uses linear illumination and a flexible tank to turn liquid resins into flawless prints. It all starts with the new custom-designed light processing unit. This LPU uses a compact system of lenses and mirrors to deliver uniform illumination, resulting in accurate, repeatable prints. The flexible tank reduces peel forces, providing incredible surface finish with fewer, light-touch supports. The Form 3's integrated sensors monitor and maintain ideal conditions, for consistent performance over time. Engineers can switch between materials in seconds, and user-replaceable components maximize uptime. The Form 3L uses the same powerful LFS process but with 2 LPU's. Two lasers simultaneously build large, dense parts fast. It has an increased build volume, 5 x larger than the Form 3, for larger scale models and prototypes, or multiple [...]

HP and Smile Direct Club Collaborate

Smile Direct Club disrupting $12 billion orthodontics industry with affordable, personalized, and sustainable 3D production; nearly 20 million 3D printed mouth molds in next year. https://cimquesttv.wistia.com/medias/g2ik6jas6x?embedType=async&videoFoam=true&videoWidth=640 HP Inc. and SmileDirectClub, the pioneer of teledentistry and market leader in doctor-directed, remote clear aligner therapy, announced an expanded collaboration to revolutionize the way that millions of people can achieve a straighter smile. SmileDirectClub is powering its digital differentiation and rapid manufacturing expansion of clear aligners with HP’s Jet Fusion 3D printing solutions, making it the largest producer of Multi Jet Fusion 3D printed parts in the country. “SmileDirectClub is digitally transforming the traditional orthodontics industry, making it more personal, affordable, and convenient for millions of consumers to achieve a smile they’ll love,” said Alex Fenkell, co-founder, SmileDirectClub. “HP’s breakthrough 3D printing and data intelligence platform makes this level of disruption possible for us, pushing productivity, quality, and manufacturing predictability to unprecedented levels, all with economics that allow us to pass on savings to the consumers seeking treatment using our teledentistry platform.” Disrupting the 120-Year-Old Orthodontics Industry SmileDirectClub co-founders Alex Fenkell and Jordan Katzman first met as teens with metal braces at summer camp, later deciding that innovations in technology and telehealth could democratize access [...]

Keynote Speaker for Xpand3D Event Just Announced

Xpand3D is excited to announce the first keynote speaker: Ric Fulop, CEO and Co-Founder of Desktop Metal. Ric Fulop is the CEO and co-founder of Desktop Metal, a company committed to accelerating the transformation of manufacturing with end-to-end metal 3D printing solutions. Founded in 2015 by leaders in advanced manufacturing, materials science, and robotics, the company is addressing the unmet challenges of speed, cost, and quality to make metal 3D printing an essential tool for engineers and manufacturers around the world. Stay tuned to future newsletters for the exact schedule of speakers and presentations. Early Bird registration is now open for Xpand3D. This upcoming event will cover all aspects of the 3D printing, design and manufacturing industries - all in one place, over the course of three days. Mark your calendars and SAVE THE DATE October 15 - 17, 2019 Where Manufacturing Happens Click the button below to secure your spot and register for this event. For exhibitor or sponsorship info, please contact Emily Moore at emoore@cimquest-inc.com. Register Here