Metal Casting Basics

For applications where parts require fine features or complex geometries, casting remains a cost-effective and highly capable manufacturing process, producing critical components for aerospace, automotive, and medical applications.

Metal casting dates back to at least 3200 B.C., progressing through many cycles of innovation to become the reliable, modernized process it is now. Today, industrial metal casting processes are used to make everything from knee implants to tractor parts.

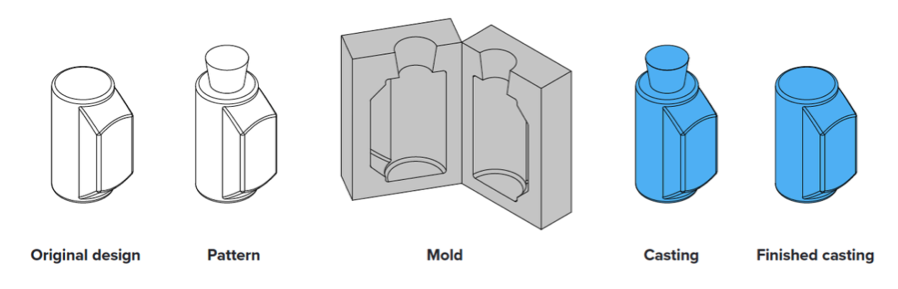

The basic process to create cast metal parts has a few steps common across different techniques:

- A manufacturer creates a pattern that represents the part, either as a removable element to make an impression in a material like sand, or left inside of the mold material and subsequently burned or melted out.

- In either case, a cavity in the shape of the pattern is left behind, and molten metal is poured in.

- The molten metal cools, and the mold is either opened up or broken apart to retrieve the casting.

- Cast parts have vestiges of the process where vents, gates, and feeders that direct gases and molten metal during casting. To finish the cast parts, a foundry worker trims away excess material, and files, grinds, machines, or sandblasts parts to achieve final geometry and surface requirements. In some cases, the cast parts are also heat treated.

An illustration of the steps from original design through final casting.

In any casting process, two basic forms must be fabricated: the pattern and a mold of some kind. The pattern is essentially a slightly modified version of the part to be produced.

The design for the pattern differs from the final part geometry in a few ways:

- Patterns are scaled up to compensate for shrinkage that occurs in casting.

- Patterns often contain elements relevant for the casting process that will not be present in the final part (e.g., gates for metal to flow through at a controlled rate, vents for gases to escape through, etc.).

- Patterns may have certain features oversized or filled in to accommodate secondary operations used to produce very tight tolerance features (boring, tapping, etc.).

Patterns are typically made from wood, foam, plastic, or wax. Sometimes the pattern design will incorporate elements related to the casting process, like gates for molten metal to flow through.

A mold includes the negative of the pattern along with sprues, gates, vents, risers, and other features to control the flow of metal and gases during casting.

Molds are made from a variety of materials (e.g. ceramic, graphite, plaster, sand) and must be able to withstand the high temperatures and mechanical stresses of the casting process.

Stay tuned for next week’s blog post where we will continue our discussion on this topic and explain “direct investment casting.”

This information was reprinted from the Formlabs blog.

Leave A Comment