Enhancing Radiation Shielding Using 3D Printing, Scanning, and Geomagic Design X

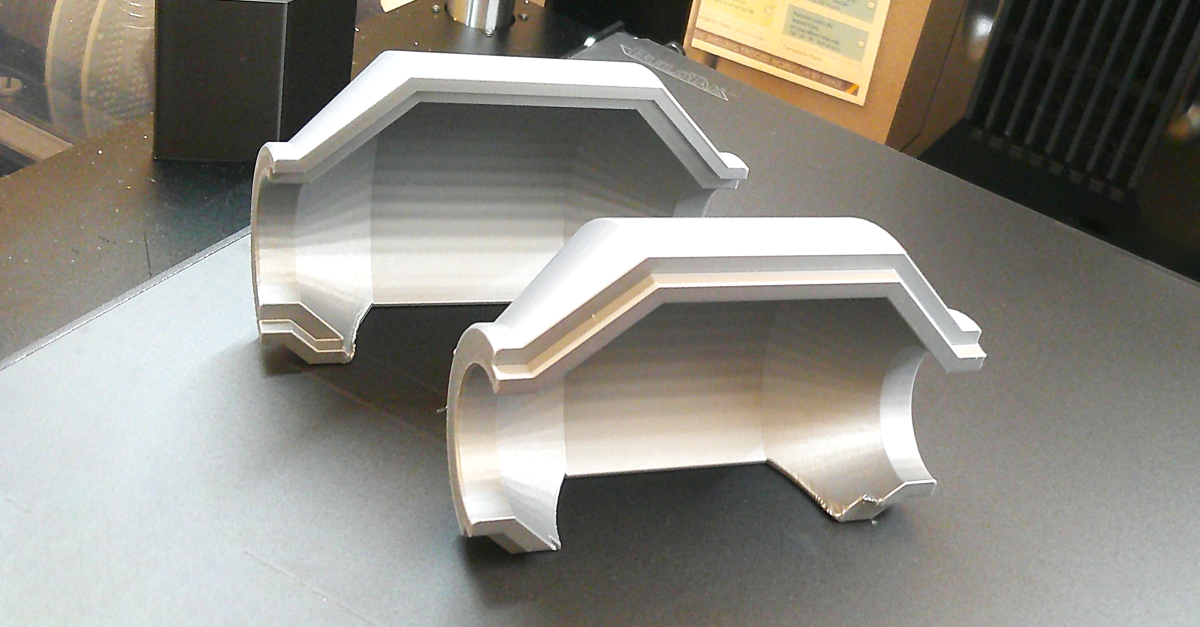

Enhancing Radiation Shielding Using 3D Printing, Scanning, and Geomagic Design X Nuclear plants could become the main source of clean energy, but their success is tied to preventing hazardous radiation. Canadian electric company Bruce Power, with a nuclear power station on Lake Huron, embarked on developing a novel radiation shielding approach. The company uses a 3D scanning and 3D printing workflow with tungsten-impregnated filament to make custom shielding components. Barely a year after the initiative [...]