Welcome to the Cimquest Blog!

Check here often to find Cimquest, Mastercam and 3D Printing happenings, product offerings and update info along with general Industry trends and breaking news.

April 2024

HP Unveils Disruptive New Material for 3D Polymers Production

Accel Digital Solutions, Decathlon, Erpro Group, and Materialise are achieving unparalleled surface aesthetics and cost-efficiency in parts production

HP Inc. will showcase parts at the annual AMUG (Additive Manufacturing User Group) Conference using a new material qualified for its industrial 3D polymers solutions. Developed with Arkema, the new PA 12 S material sets the standard for surface aesthetics, while reducing costs […]

The Impossible Becomes Reality With 3D Scanning

When should you perform 3D scanning?

As with other tech novelties, the unbridled enthusiasm for scanners makes it difficult to differentiate the hype from the valuable applications.

Should you decide to seek out the answer in the vast online wilderness, you’ll discover some interesting passion projects and creative feats of engineering. Scanning body parts and boats seems to be a particularly popular pastime!

Fun and games aside, […]

Introducing Kimya PEI Support: Simplifying Your 3D Printing Process

Introducing Kimya PEI Support, a new high-performance breakaway support filament meticulously designed to elevate your 3D printing experience. Tailored for use with Kimya PEI-9085 and Kimya PEI- 1010 filaments, both based on ULTEM by Sabic, this innovative support material brings a new level of functionality to your printing of ultramaterial parts.

Perfect Synergy with ULTEM-based PEI 3D printed parts

Crafted with precision, Kimya PEI Support establishes a perfect […]

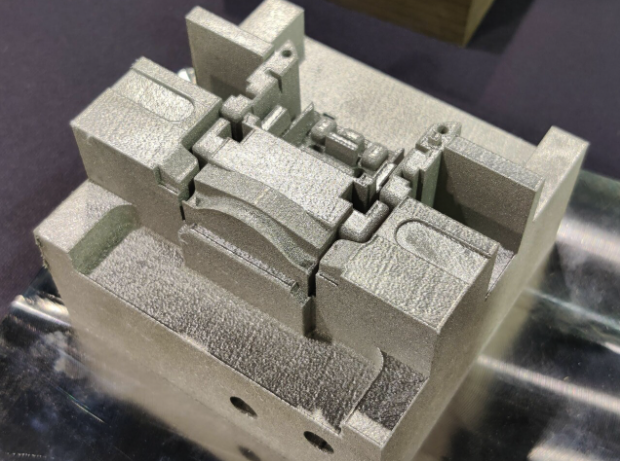

Xact Metal Announces Partnership with Uddeholm to Offer Corrax Tool Steel Powder

With an aim to expand access to affordable metal 3D printing for small-to-medium size companies and decentralize additive manufacturing, today Xact Metal™ is excited to announce its partnership with Uddeholm, a voestalpine company, to supply Corrax tool steel for additive manufacturing, in support of the company’s expansion into the tooling and molding space.

Xact Metal’s goal to break down barriers into powder-bed fusion […]

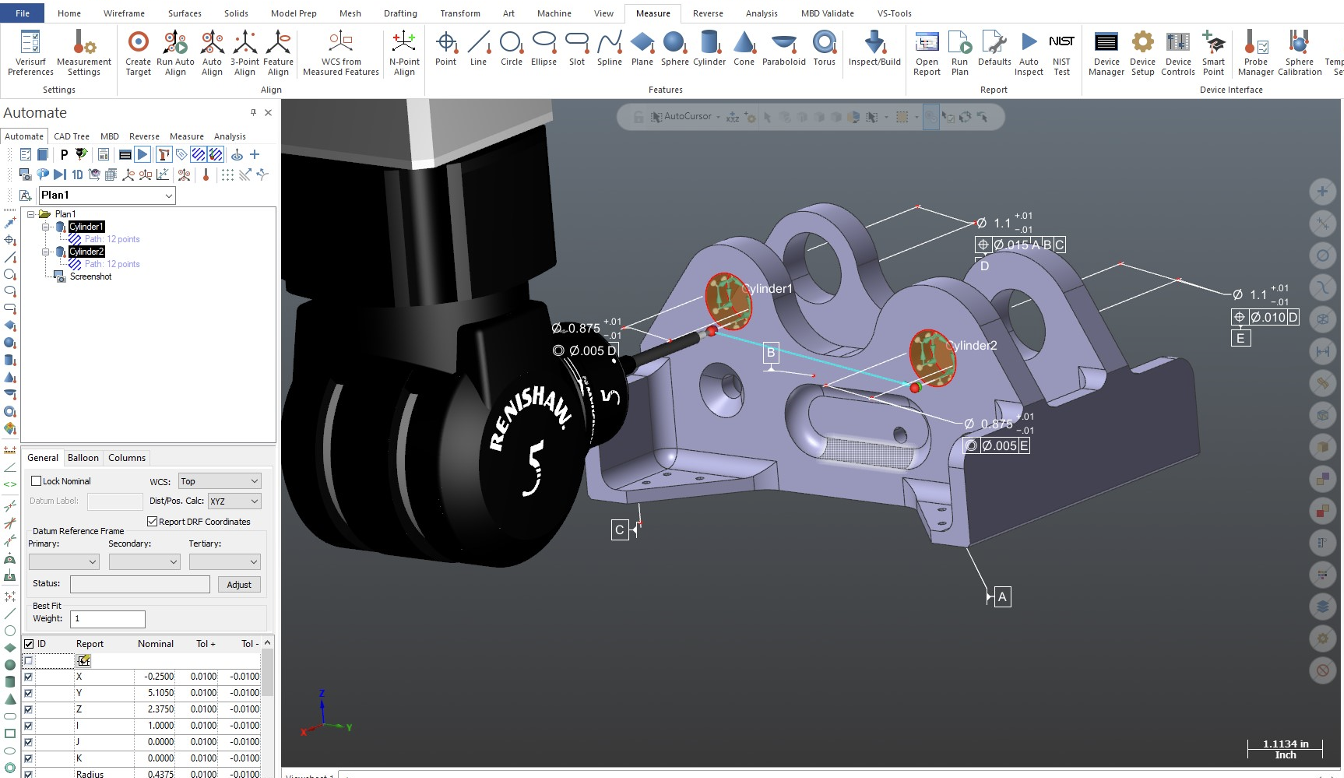

Introducing Verisurf Universal CMM

Attention all Mastercam users who inspect parts using a CMM . . .

You no longer need to tolerate the programming system that came with your Coordinate Measuring Machine (CMM). If you have multiple CMM’s, each with their own clumsy programming system, you can now program them all using a single simple-to-use software product that runs from within the user-friendly Mastercam programming environment.

While CMM’s are a necessity in most […]

Performing Calipers-only Inspection

Many Mastercam users still work from 2D prints to machine parts and don’t have solid models. In these cases, manual “virtual” measurement tools may still be used to take measurements even in the absence of a solid model. Let’s imagine that you just machined the connecting arm below from a 2D print and don’t have a nominal CAD model to compare against.

In previous blog posts, we showed how to create Regions on the model and […]