Have you ever needed to inspect parts in a CMM, without having a master part? Automated CMMs can be a great time saver when inspecting parts on the shop floor. Traditionally, a master part is measured to generate a master data set.

The same routine is then automated and used to measure each production part. Each production data set is then compared to the master data set to determine the actual size of the part and whether it is within user defined tolerances. But what if you don’t have a master part available, or one that was closely produced to drawing nominal? This is where the CMM Master can be a great solution.

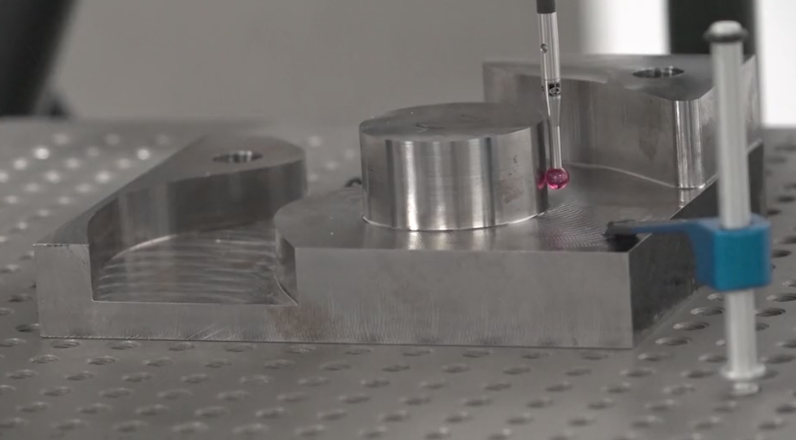

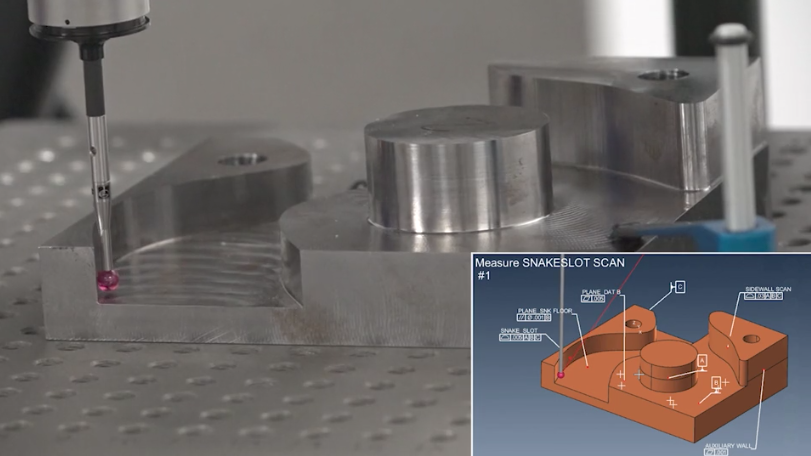

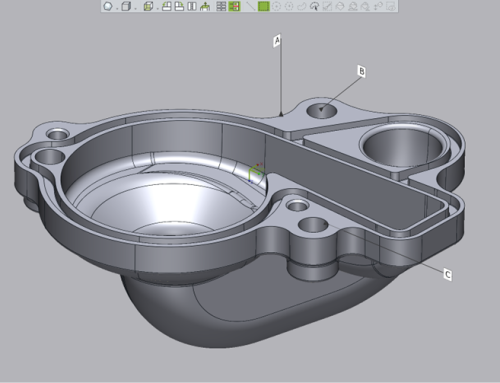

The CMM Master, based on the Renishaw Equator platform, is a portable, automated CMM, calibrated for high production shop floor inspection. In conjunction with the Verisurf software, it is volumetrically error mapped to increase the traditional Renishaw Equator accuracy down to .0005”. Here you see the CMM Master running an automated measurement routine. When it’s done, it automatically generates a date and time stamped report.

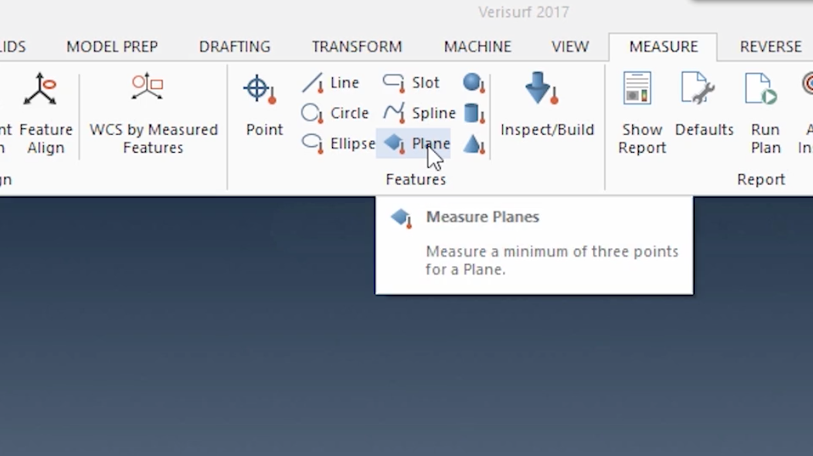

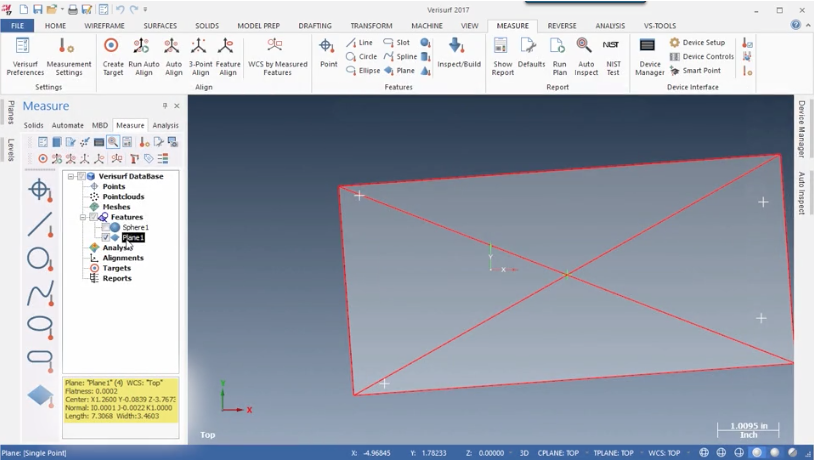

One thing that makes the CMM Master unique is that a master part is not required in order to perform on the fly measurements. You can remove the part that was originally aligned on the machine and in use by the CMM Master, and replace it with a completely different part. Fixture the new part to the platen, but do not align it or calibrate it in any kind of way. Then you can use the Measure Module in the Verisurf software to simply tell it what type of geometry you’re looking to measure and use the probe to start collecting data.

When complete, it provides the measurements you were looking for, all without having to first digitize a master part. This is a great time saver.

As you can see, the CMM Master along with the Verisurf software is a great tool that not only easily creates automated measurement routines, but also captures on the fly measurements, without even having a master part.

Please be sure to sign up for our 2 Minute Tuesday video series to receive tips and tricks like this one in video form every week. More info at the button below.

Leave A Comment