by Shawn Spinneweber

Have you heard about Mastercam’s Dynamic Power Cutting? Did you know that it could save you cycle time and extend your tool life?

When thinking of a CNC mill cycle, typically the first factor thought about is the cycle time and the “Q” is overlooked. The Q is the Metal Removal Rate (MRR). MRR enables you to compare different toolpaths to see how efficient you can remove a volume of material in a period of time. Depending on the machine horsepower, torque, feed rate, etc… will depend on how the Q is applied. If you have a rigid 50 taper high horsepower mill versus a lower horsepower 40 taper with super fast feed rates then your approach of how you want remove large amounts of material will be different.

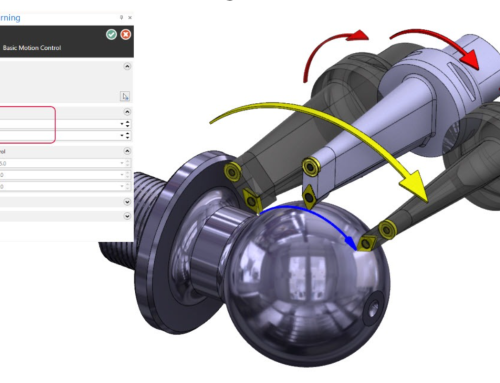

Dynamic Motion gives you the ability to apply different toolpaths to meet different machines, materials, and tool characteristics and they all affect the Q. Consider these points:

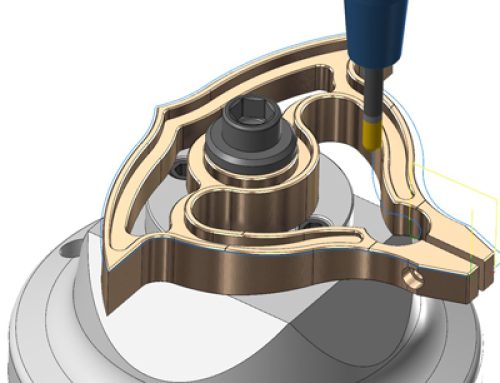

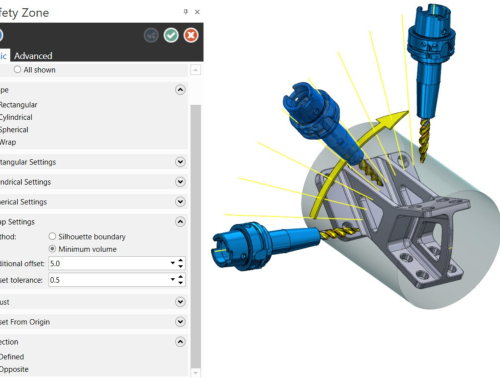

1. The Dynamic Motion toolpath calculates an efficient entrance into the cut and maintains it throughout the cut and finally to the exit of the tool. It utilizes radial chip thinning to maintain a consistent chip load and surface footage to cut very quickly. The less the step over, the more feedrate can be applied to maintain a particular chip load so you can cut faster. What are the benefits of doing this? Extended tool life, extended spindle life, maximized cutting process, shorter cycle times, reduced tool breakage, etc…

2. Dynamic Motion considers the width of cut or step over in conjunction with the tool entrance, exit, and chip load so the step over effects the amount of horsepower and torque needed to cut the material and helps maintain a constant load during the cut. The step over can be adjusted depending on the machine, material, and cutting tool. The less step over, the less torque needed to cut; perfect for lower HP/torque machines.

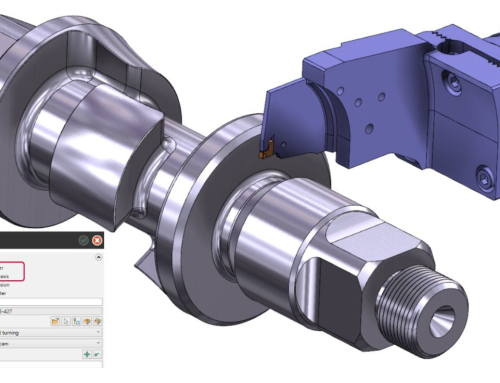

3. Now let’s add some depth to this equation, specifically depth of cut. Most traditional methods use ½ to ⅝ width of cut and short depth of cut (½ to 1 X Diameter). Dynamic is going to go anywhere from 1 to 3X diameter in depth. This lets you utilize all or almost all of the flute length which lets you crank up the “Q” factor (cubic inches per minute) by maximizing the metal removal in width (step over), and Depth/LOC (length of cut) at a particular rate of inches per minute.

So let’s consider 3 different types of CNC Mills.

#1 – High HP, high torque, rigid box way, 50 taper or big HSK spindle type

#2 – Mid HP, High RPM, low/mid torque, high feed rate, linear guide, 40 taper

#3 – Low HP, low feed rate, entry level CNC – think CNC retro fitted Bridgeport style mill

Which one is best suited for Dynamic Motion? Trick question? Maybe, it depends on your programmer and if he/she understands how to apply the techniques of Dynamic Motion and if he or she understands the machine being programming. The answer is that all 3 types of mills will benefit from using Dynamic Motion.

Machines #2 and #3 benefit using Dynamic Speed toolpaths because with less step over, less torque is needed so these machines can run deep depths and remove the material much quicker than they would traditionally.

Machine #1 has been left out of the application because of tooling until now. Machines like #1 have the torque, rigidity, and HP so you can increase the step over dramatically (as much as 3/4 of the tool diameter) and go 2x diameter in depth while still running traditional speeds and feeds. This results in an incredible amount of metal removed in a short amount of time.

You do need to understand the tooling side of things and have a certain amount of knowledge to apply these techniques, but the results will be cycle time saved and tool life to extended, This new technique is called “Dynamic Power Cutting” and if you don’t believe it’s possible, then give us a chance to prove it!

Contact us to learn more by clicking on the button below.

Leave A Comment