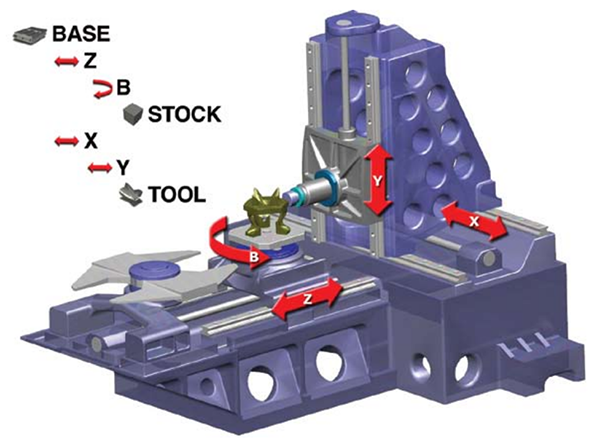

In any CNC milling machine, the workpiece and cutting tool move along set axes to cut out parts. How they move and in which directions is dependent on which type of machining center they are. Here are the differences between horizontal and vertical CNC machines.

Horizontal CNC Milling

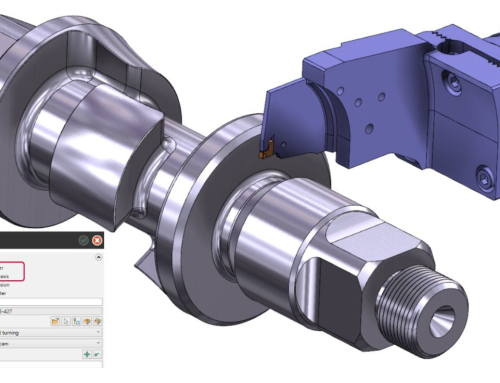

A horizontal milling machine, also known as a horizontal machining center or HMC, features a cutting tool that is oriented horizontally. Their horizontal design allows chips to fall away naturally and safely, which helps to achieve smooth, quality finishes. HMCs are most commonly used for larger volume jobs and have more machining power than the average vertical CNC machine.

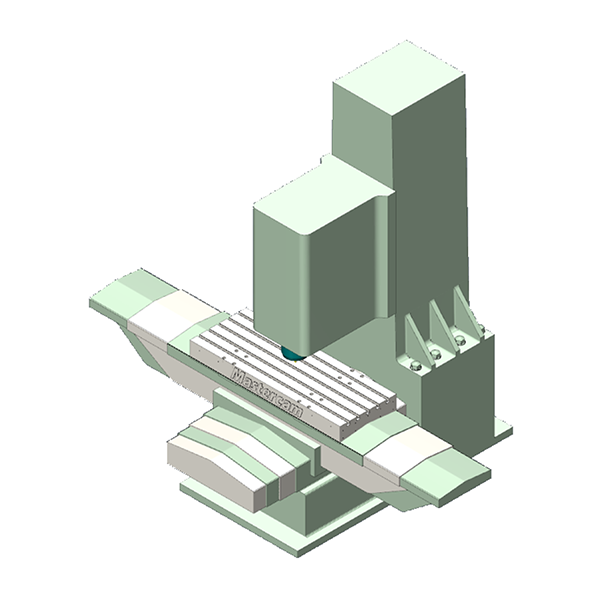

Vertical CNC Milling

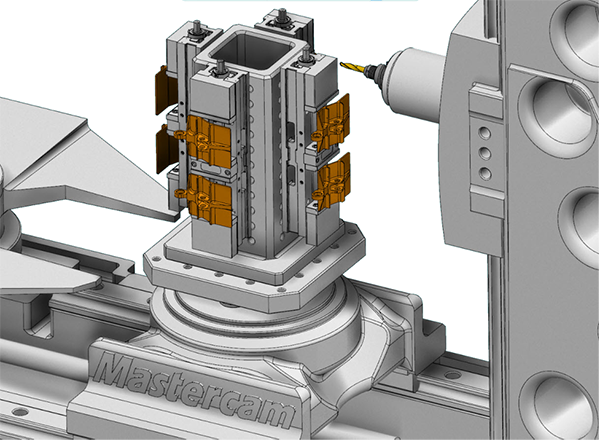

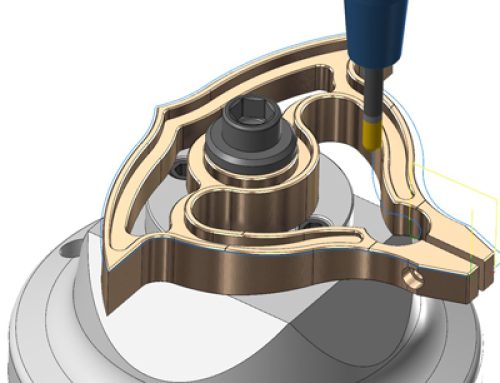

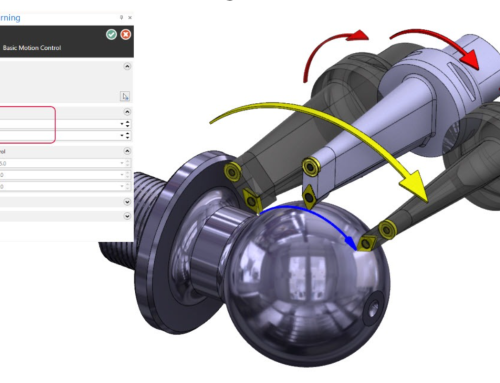

The most commonly used milling machine is a vertical machine, but there are two main styles: turret mills and bed mills. In both, the cutting tool is mounted vertically. On a turret-style vertical machining center (VMC), the bed moves while the spindle remains in place. Bed mills have the workpiece slide along the bed.

How to Choose Between Horizontal or Vertical Machining

Both styles of machining come with their respective pros and cons, as well as widely differing configurations and price points. VMCs usually have a lower upfront cost than HMCs, and offer greater visibility while machining. HMCs, though, offer more power and are best suited for large quantities of parts or more intricate parts.

Turret mills—great for molds and parts with lots of cavities to be bored, but not suited for larger pieces, because the entire bed must move.

Bed mills—good for parts that require basic drilling and grooving operations, but most can’t mount more than one spindle at a time for more complex machining.

Horizontal mills—best for large parts, high volume jobs, and any machining that requires more power for tougher material.

Selecting the right machine for your shop requires deep consideration. Here are some questions to help you get started:

- Are you planning to run one-offs or production?

- What material/s are you planning to cut?

- What kind of accuracy are you aiming for?

- What are the general dimensions of the parts you are planning to run?

- What is your budget?

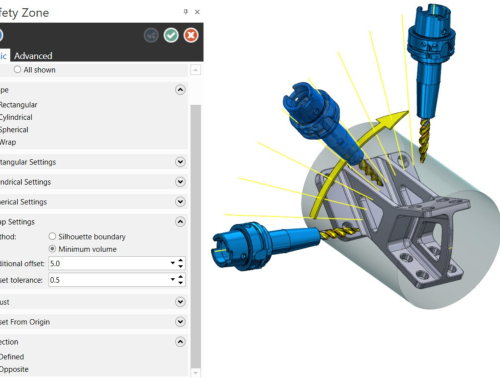

- Is your current CAD/CAM capable of driving the new machine?

- Are you up to date with your training?

- Do you have a proper floor/foundation to place the machine on?

- Are you running shifts in your shop?

- Are your programmer/s and operators enthusiastic about learning something new?

- Are you ready to get very busy?

After you select your machine, it’s time to explore the software to run it. Click below for more details about Mastercam.

Leave A Comment