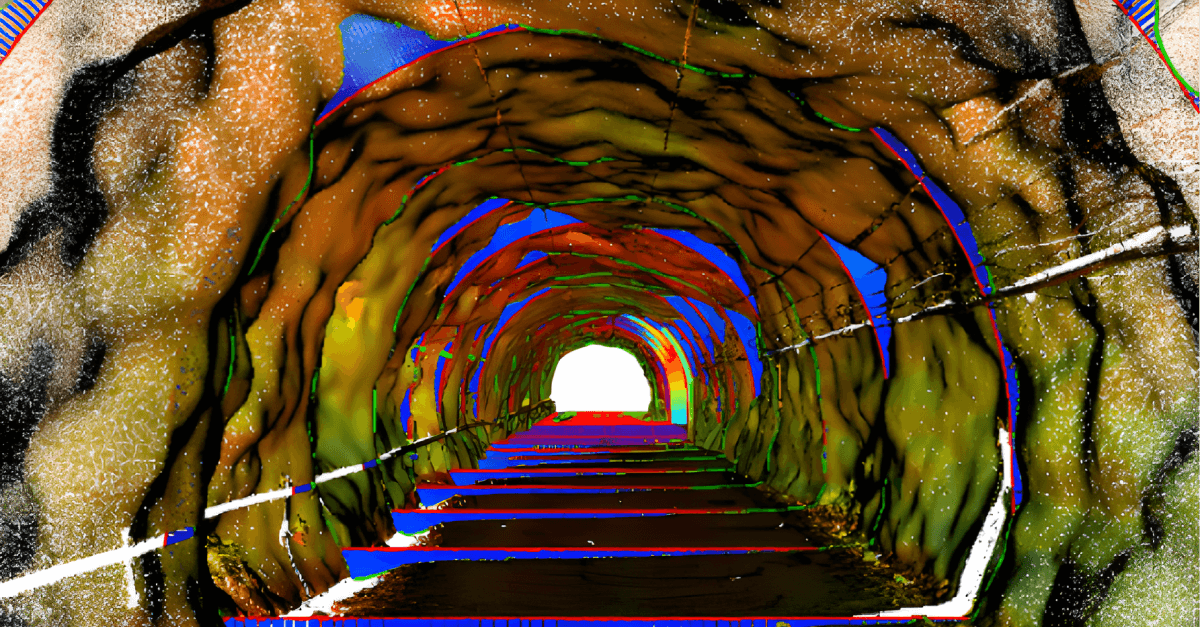

3D scan of an underground tunnel.

3D scanning software facilitates data processing for various applications like wear analysis, volumetric load scanning, spatial visualization, and reverse engineering. Exploring its advantages may help you understand the benefits for your mining operation.

Efficiency

With 3D scanning, mining companies can acquire accurate information about operations up to 10 times faster. They can map tunnel profiles, stockpile volumes, pits, and caves in minutes without much expertise. The digital data set can be accessed and analyzed later, reducing interruptions and downtime. Sectioning, a time-consuming surveying process, can be done in minutes with 3D scanning, allowing surveyors to produce thousands of sections quickly.

Accuracy

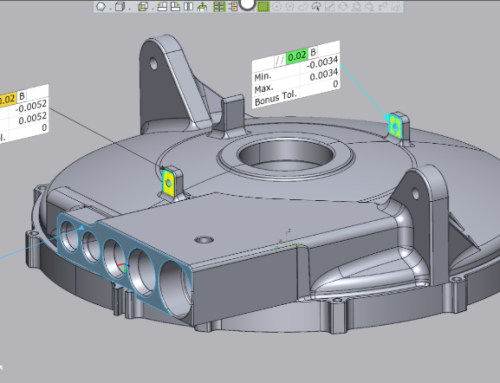

3D scanners capture millions of data points to create precise 3D models of mine locations and equipment, improving accuracy over original plans. These scans can be used for future surveys to highlight changes and assist with upgrades or modifications.

Every mine is different and 3D scanning enables engineers to easily design a custom solution for each.

Flexibility

3D scanning technologies offer more flexibility than traditional surveying. Scanners can be used by the mining team or attached to drones, trolleys, or robots to access any space, even without GPS.

Continuity

3D scan data can be accessed by off-site teams for quick insights. When stored in the cloud, it may help rock engineering teams identify deformations, geology teams ensure correct shotcrete thickness, and ventilation teams analyze airflow with CFD.

Safety

3D scanning improves worker safety by reducing time in risky areas and minimizing repeat visits. It allows dangerous surveying to be done by drones or robots. Scans help identify problem areas and risks, enabling prompt action. Titan Engineered Solutions uses 3D scanning to design custom solutions that fit perfectly, ensuring first-time-right designs.

Titan Engineered Solutions uses 3D scanning to deliver first-time-right custom mining solutions.

The Future of 3D Scanning in Mining

New mining technology aims to improve efficiency and worker safety. 3D scanning achieves both goals and will continue to advance. It provides real-time insights into mining processes and structural integrity. With software like Geomagic Design X, Control X, or Wrap, companies may gain a more accurate picture of operations. Contact Cimquest today to learn more!

Leave A Comment