Innovative Implant Design: From Imaging to Surgical Application

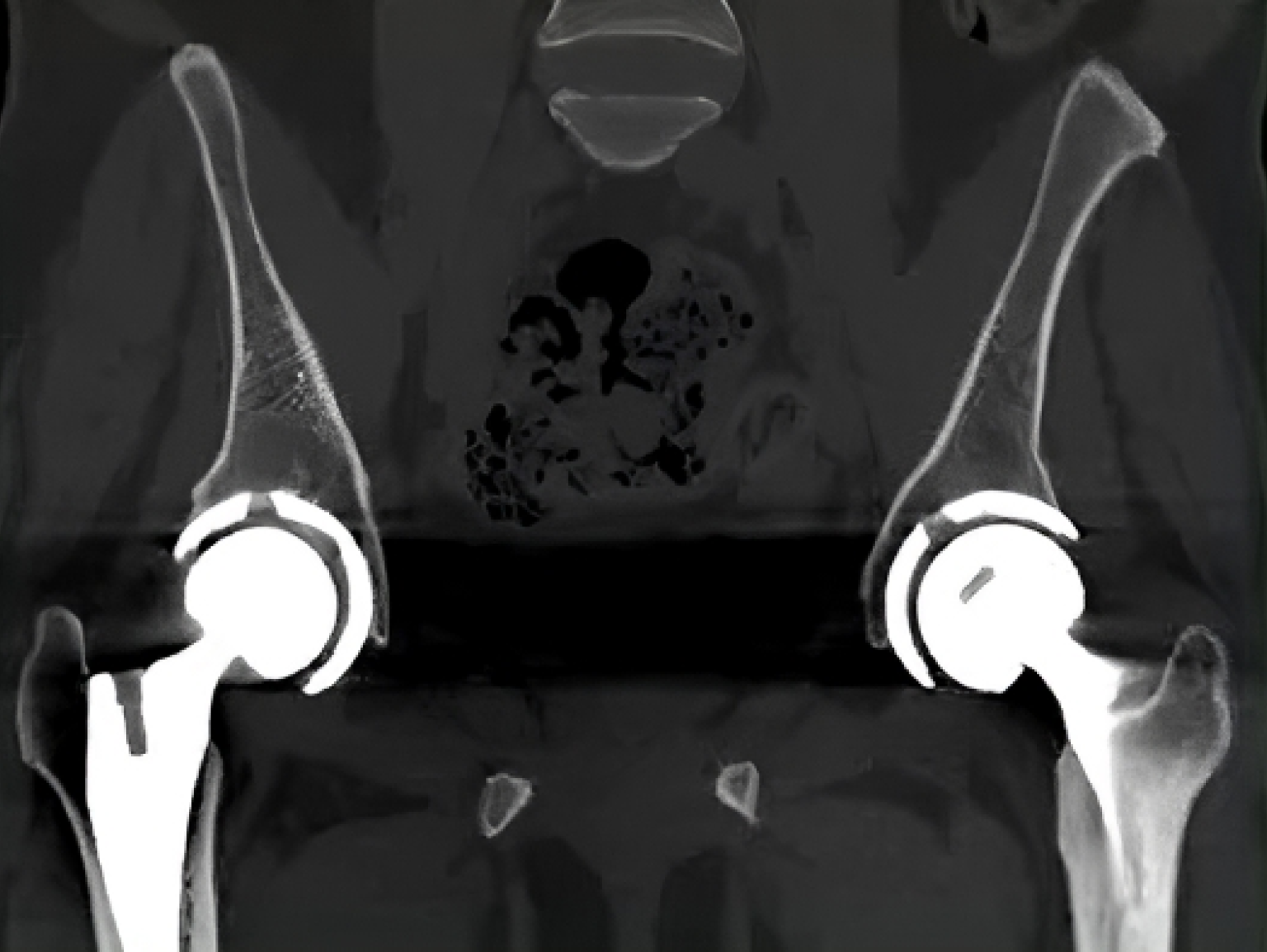

The next step must convert 2D medical images into a 3D model using Simpleware. This software imports image data and uses manual and AI-driven segmentation to define anatomical structures, generating a 3D model for accurate measurements.

The 3D model must then be exported to Geomagic Freeform, which is quick and easy. The resulting model can include labels and a bone density color map.

From 3D modeling to printable design

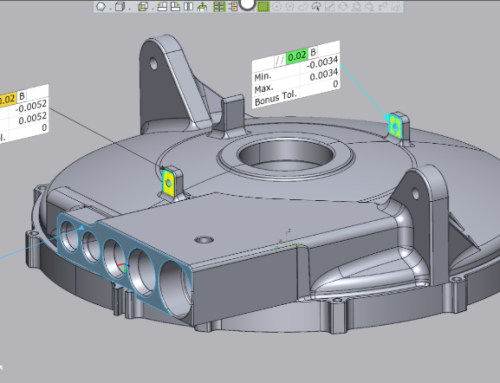

Freeform must produce manufacturable, engineered objects with complex and organic forms, ideal for patient-specific hip implants.

Traditional CAD programs struggle with organic shapes, but Freeform uses voxels, making it easy to represent complex structures.

Freeform includes interactive tools for complex models. The design team at implantcast GmbH, specifically C-Fit 3D, handles over 1,000 bespoke implants annually. The software’s haptic device, resembling a pen, provides real-time physical feedback for shaping models.

Collaborating with the surgical team

The C-Fit 3D team must collaborate closely with the surgical team. Discussing the 3D model helps understand the hip defect and bone preparation, aiming to maximize bone-implant contact for better osteointegration. Recent improvements increased contact surface from 12% to 69%.

Once finalized, the implant must be 3D printed in titanium. Post-surgery, patient outcomes must be evaluated through clinical and radiological analysis.

The Freeform team will continue collaborating with Simpleware and implantcast to optimize workflows for more accurate patient-specific implants.

Leave A Comment