Reprint from Cutting Tool Engineering

The evolution of efficiently removing material has basically unfolded like this:

Traditional machining. We used the speeds and feeds recommended in catalogs from cutting tool manufacturers. We cut a 50% step-over as a rule of thumb, and while maybe it wasn’t the most efficient process in the world, we didn’t know the difference.

Radial chip thinning. We still used the machining parameters from the cutting tool catalogs, yet we were also able to increase the feed rates and metal removal rates when stepping over less than 50% of the tool diameter. We began to increase productivity—when we went in a straight line, that is. Fluctuations in tool load continued to limit productivity.

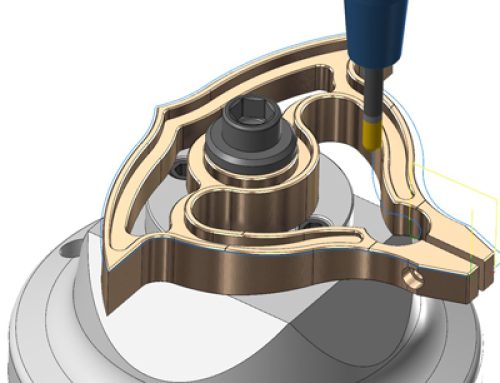

Dynamic Motion. This is where we have been for about 10 years. We started with the radial chip thinning principles and have been increasing feed rates, step-downs and removal rates. The cutting tool motion modifies dynamically to produce consistent, optimal chips—we call this constant chip load machining—and offers efficient cutting conditions regardless of workpiece geometry.

With Dynamic Motion, cutting tool motion modifies dynamically to produce consistent, optimal chips. Image courtesy of CNC Software

For several years, the Dynamic Motion application has proven itself again and again for those who have adopted these material-aware toolpaths. As always, we learn from customers who use our software in the real world day in, day out. They eagerly tell us about their successes and challenges. With each release of our software package, we tweak this or that based on their valuable feedback.

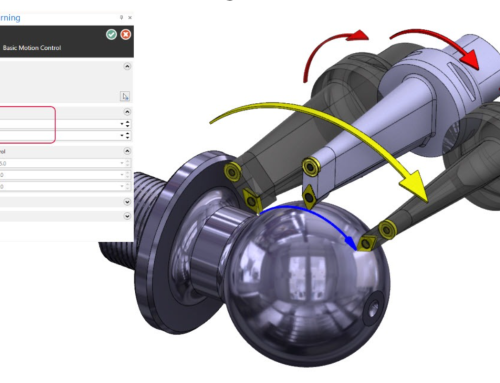

What we are hearing and addressing now is this: Many customers are becoming so comfortable with Dynamic Motion that they want to be as aggressive as possible, such as stepping down three or even four times the tool diameter. In many cases, that’s just fine. However, going around corners can be troublesome because the cutting tool tends to want to grab that edge. Then the metal can grab the tool, and the metal can bend. As such, we’re working on future technology in the Dynamic Motion engine to aid users who are trying to be very aggressive or those machining challenging materials.

Also, sometimes during milling, sharp, knife-edge corners are created simply by the way the tool moves around an area. Tall, skinny islands or peninsulas can be made accidentally. When the tool hits those, tool pressure might flex material away from the tool so when it comes around the other side, there’s more material in its path than expected. These tall, thin pieces of material can damage tools or cause other issues.

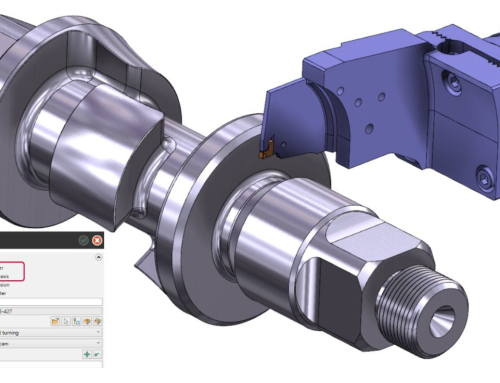

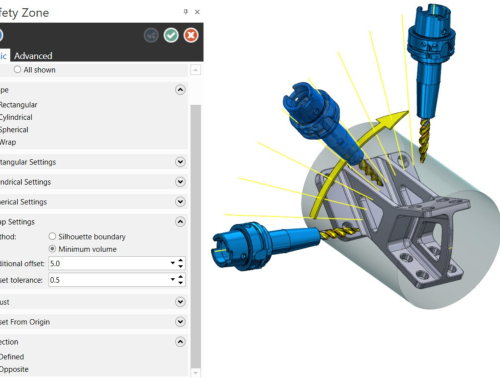

CNC Software is working on future technology in Mastercam’s Dynamic Motion engine. Photo credit: CNC Software

CNC Software is working on future technology in Mastercam’s Dynamic Motion engine to aid users who are trying to be very aggressive or those machining challenging materials. Image courtesy of CNC Software

The question now surrounds how we can provide alternative, safe measures and alleviate or even prevent this particular condition. Simulating processes with the software often reveals the trend, and the programmer can adjust the code to back off in certain areas. Furthermore, soon there will be other approaches to select in the software when the condition is recognized or likely to occur—for example, taking multiple-depth cuts in strategic areas at appropriate moments. Instead of stepping down three times the diameter in one cut, the programmer might choose to take it down one time the diameter three times around.

There could be other ways to address this, such as taking a software development course to predict conditions and automatically adjust processes to avoid them. That would call for extreme computational complexity, but the feasibility of it is worth exploring.

The main point of any discussion about the evolution of efficient removal of material is that we certainly have come a long way in the past decade. I hope that every CNC programmer at every shop uses the latest tools available—and by “tools” I mean the latest toolpaths for roughing and finishing, along with advanced cutting tools. New cutting tools and toolpaths are often developed in conjunction with each other so users can take full advantage of the benefits: longer tool life; shorter cycle times; quicker programming; greater use of smaller, less expensive cutting tools; and less time required for finishing passes. In addition, with the trend of more manufacturing automation equipment being installed, there’s the benefit of running lights out with greater confidence.

For more information on Mastercam, please click the button below.

Leave A Comment