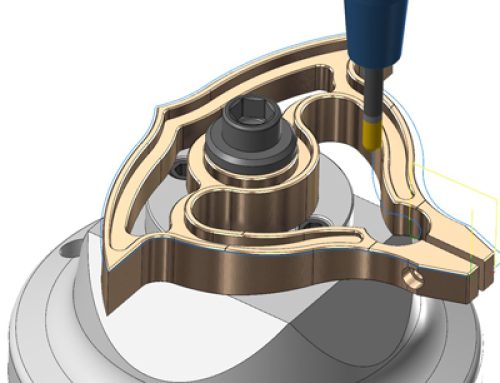

There is a new option in Mastercam X9 called “Linked Edges” in toolpath chaining for solids. In previous versions, solid chaining was limited to picking loops of edges on individual faces. Now, thanks to technology first seen in Mastercam for SOLIDWORKS, tangent edges of adjacent faces can be linked to produce 2D and 3D cuts.

It is interesting to note that the fillet radius around the base of the above part is actually made up of several different faces. In earlier versions we would have to create curves on the tangent edges and chain that wireframe geometry to make the cut.

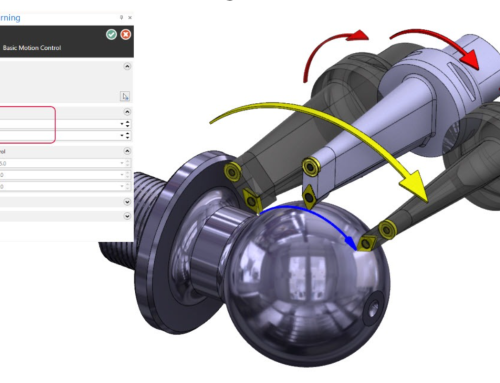

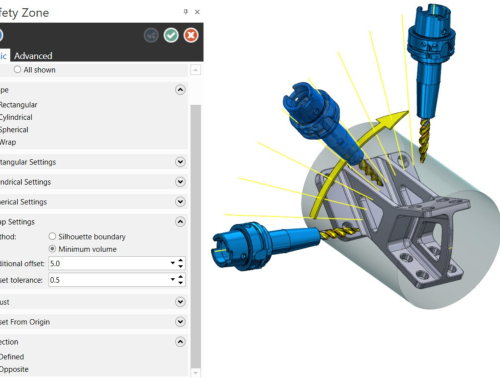

In Mastercam for SOLIDWORKS chaining can be propagated along tangent edges or along the current tool plane. Now in standalone Mastercam X9 we can activate the button (shown below) and chain through the linked edges. This behavior is similar to ‘partial chain in wait state’ used in wireframe chaining.

Next, when these edges are linked together they form a 3D chain which can drive a 3D contour. Although this might seem a strange feature to cut like this, it does prove out the concept.

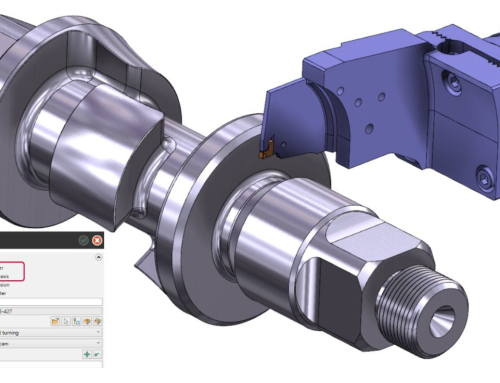

Finally, these same 3D edges can be projected into a 2D cut. Simply go to the cut parameters branch, switch the contour type to 2D, then select a depth in the linking parameters and click OK.

It’s that easy. 3D Linked Edge chaining even works with 2D Dynamic Cutting.

As you can see, Mastercam’s advances in processing Solids help make your job easier with every new development.

Leave A Comment