To stay competitive in today’s rapidly changing manufacturing environment it is imperative that you stay on top of new and emerging technologies. Cimquest is offering the first of a series of Manufacturing Training classes that we are developing to take you to the next level and improve your machining production. This is an intense course on how to implement, evaluate and select components for high efficiency milling to get shorter cycle times, reduce tool wear and extend machine life. You will learn guidelines to selecting key components with hands on interactions to build your ability in identifying and creating an efficient milling process. At the completion of this course you will be able to analyze the whole milling process, select the correct components, and create an efficient CNC milling process to increase productivity using Mastercam Dynamic Motion. More details on the course are below.

Prerequisites: Basic proficiency in Mastercam Mill, and knowledge of CNC mill setup and operation.

Who Should Attend: New or current Mastercam programmers, CNC machinists, recent CNC technical or college grads, engineers or anyone with basic Mastercam programming ability.

Major Topics

- Identify materials and Material Groups

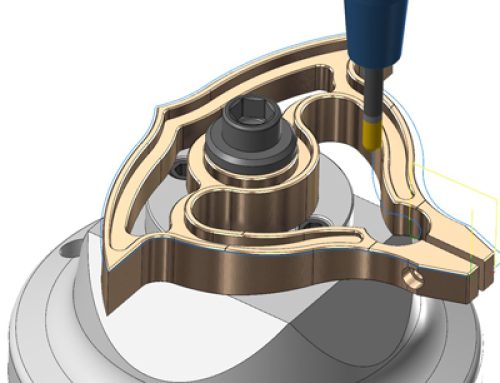

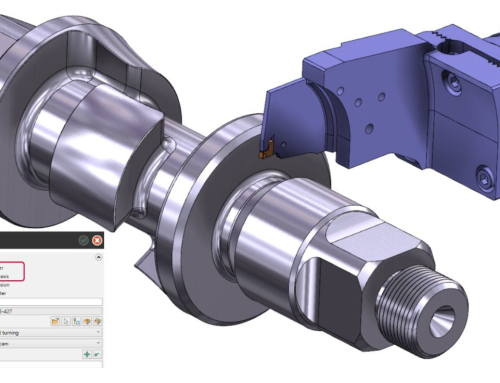

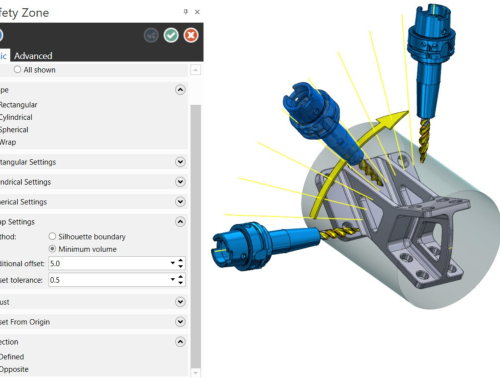

- End mill selection and calculate parameters for specific material groups and programming methods o Tool holder selection and maintenance

- Coolant o Work holding methods for different part features, materials and programming methods

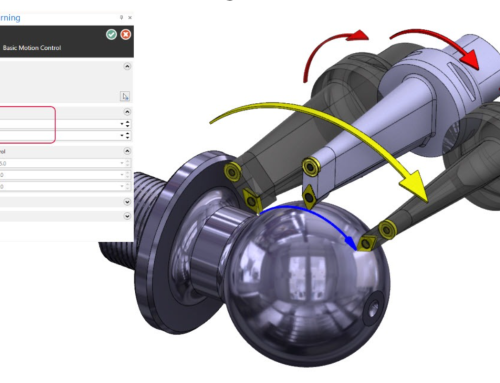

- CNC machine specifications

- Program multiple parts with different geometry using Mastercam Dynamic Motion

- Calculate and analyze productivity outcome of Dynamic programming

- Complete a final project o Live milling demonstration every class

Class Size: Max 8 students

Course length: 4 days

To register for this course, please click the button below.

Leave A Comment