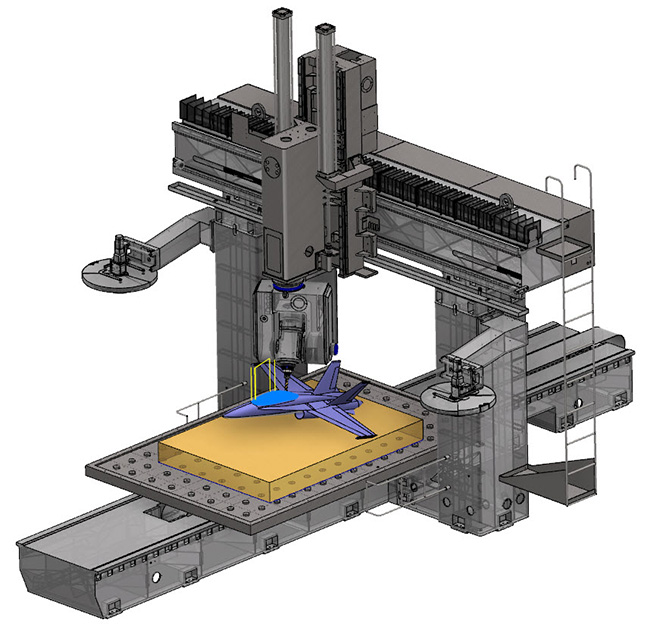

Did you know routers were first created as a solution for the cabinet industry for cutting cabinet faces out of wood? The modern router, however, comes equipped with multiaxis rotary devices and pivoting heads, making them a staple in the shops of any industry. They are now capable of cutting a variety of materials like foam, plastic, wood, aluminum, and carbon fiber.

You may already be familiar with its advanced Router software solutions. Pairing with Mastercam Art allows you to incorporate any image – a 2D drawing, clipart, photos, CAD files, etc. – into your machining code. Feature-based toolpath generation automatically calculates the best machining strategy by evaluating a part’s geometries. But the following three features can take your shop’s router work to the next level.

Mesh Editing Tools

These editing tools are incredibly useful when working with large files imported as STL models, such as architectural art, corbels, or embossed engravings.

- Decimation: Reduces the file size to expedite processing by reducing the number of facets – or data points – in the model. You can control how closely the new file imitates the old by determining the pattern of facet reduction.

- Explode Mesh: Separates the mesh model into workable areas according to flatness and size value filters that you defined.

- Refine: Improves the mesh model for finish machining or 3D printing applications by adding data points in detailed areas and reducing them in less detailed areas. Control the size of the facets and their edges to ensure accuracy.

- Trim to Plane or Trim to Surface/Sheet: Remove unwanted areas or even erroneously generated mesh data. These functions also allow you to generate a cap covering the trimmed mesh area, to prevent leaving open sections in the mesh.

- Fill Holes: Fixes gaps missed by the scanner.

- Smooth Mesh Edges: Mends ragged perimeter edges and seals gaps by generating new facets within a set tolerance. Both functions feature an automatic preview function to help with visualization.

- Modify Mesh Facets: Creates or removes individual problematic facets found by the Check Mesh function. You can then apply one of the following four modifications: Create Mesh, Remove Facets, Remove Facets and Create Mesh, or Repair.

- Smooth Area: Prepares meshes for machining by smoothing either a portion of the mesh or the entire mesh body. This feature applies up to 10 iterations of the following smoothing methods: Preserve Curvature, Minimize Curvature, Minimize Area, or Average. This is always done without changing the number of facets, focusing only on fixing the irregularities between facet vertices.

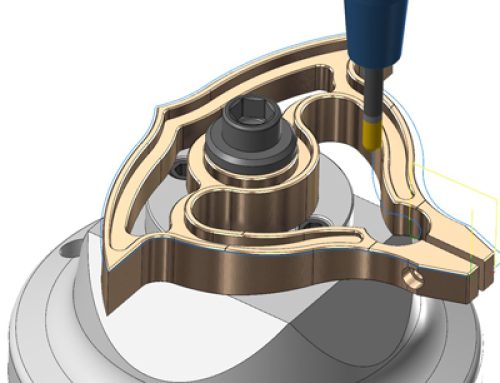

Nesting

The Disassemble function pulls solid geometries apart from the whole of the machined part so that you can focus on them one at a time. After disassembly, the software can automatically nest the entities on a virtual sheet. This nesting report arranges the pieces on the sheet so that the least material is wasted. Each component maintains its original labels and can have these labels engraved on them for easier construction. Advanced nesting features can even nest in scrap material.

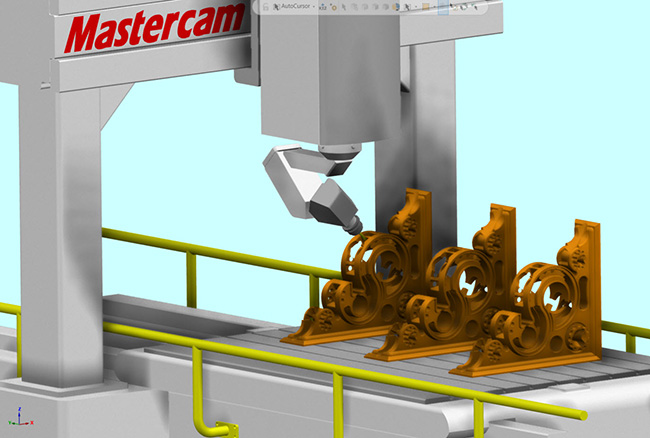

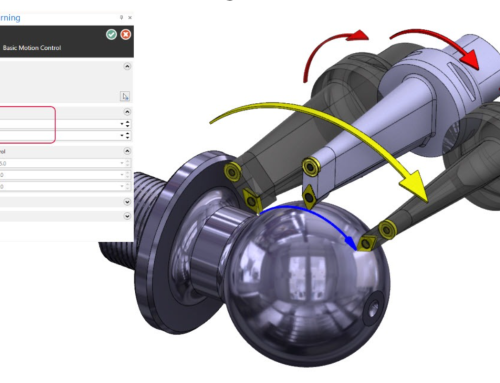

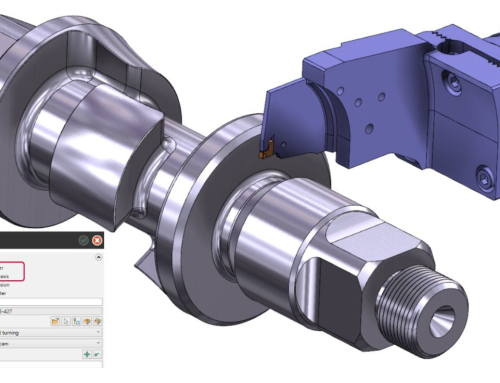

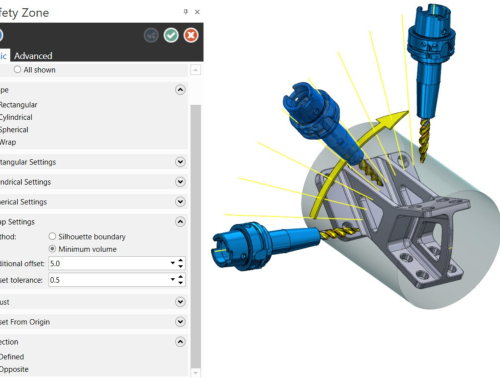

Aggregate Head Support

Some routers can change not only the cutting tool they use but also the head of the machine. There are a variety of head configurations, but the most common ones are 90-degree Head, Straight Head, Adjustable Angle Head, or 180-degree Head. Some machines can have a Combination Head. Aggregate heads are used to enable routers to cut from different angles.

Exploring Mastercam Router

Mastercam Router has grown and evolved alongside the industries it serves. CNC Software has been creating solutions, field testing solutions, gathering feedback from end-users, and perfecting those solutions for decades. And then repeating the process. Want to learn more about how you can take advantage of Router and other Mastercam solutions? Click below for more details.

Leave A Comment