Real-world ROI: Top Success Stories with 3D Printing

Do you find it challenging to understand the potential 3D printing holds for your organization? It can be easier to understand its benefits by studying real-world cases. The following companies have incorporated additive manufacturing technology into their day-to-day operations to great success, maximizing their return on investment (ROI).

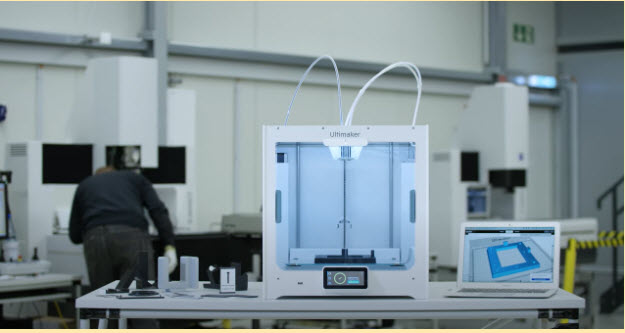

Volkswagen Autoeuropa

Volkswagen Autoeuropa uses Ultimaker 3D printers to create tools, jigs, and fixtures for use on its assembly line. By creating these parts in-house, the vehicle manufacturer saved $175,000 in its first two years of 3D printing. Specific parts are also created at a fraction of the previous time and cost.

A liftgate badge – which ensures correct positioning of a car’s emblem – costs $12 per part, with a four-day turnaround time, compared to $470 per part with a 35-day turnaround time when using an external supplier.

ERIKS

ERIKS, which offers technical components and related services to all sections of industry, uses 3D printing at its headquarters in Alkmaar, the Netherlands for a multitude of purposes. Most relevant to ROI, however, are tools used to increase productivity and safety – such as a fixture that allows for quick, accurate welding of pipes. These tools have so far enabled ERIKS to save approximately $400,000.

Snow Business

Snow Business uses Ultimaker 3D printers for prototyping, functional testing, and creating final parts for its snow machines that are used in the TV and film industry.

Nozzles for these snow machines, for example, can be 3D printed, negating the need for an SLS service, which can take up to seven days and carries a minimum $160 order. Snow Business creates the same nozzles in-house in seven hours – for $3.25 each. The company’s 3D printer paid for itself within just two weeks, Snow Business estimates.

ZEISS

Carl Zeiss Optical Components (ZEISS) currently 3D prints a unique adapter plate for each of its industrial microscopes in serial production. The company also uses Ultimaker 3D printers to create jigs and fixtures for use in its assembly line.

Using 3D printing not only saves a great deal of time, but is also extraordinarily beneficial from a cost savings and ROI perspective – what once was a $350 process now costs approximately $20 per 3D printed part.

Sylatech

Sylatech is an investment casting firm that uses 3D printing to speed up its rapid prototyping process. Before incorporating 3D printing, engineers were unable to test design functionality without using tooling investment casting. This process is time-consuming – typically taking three to four weeks – and costly, with customers paying $2,500-5,000 per tool.

On top of this, approximately 30% of tools require some sort of alteration, which can cost up to $1,200. With the help of 3D printing, however, Sylatech reduces both time and cost – with only 5% of tools needing alteration.

A yacht propellor, for instance, would typically take four weeks of development time, at a total cost of $22,100. When using Ultimaker 3D printers, that time is reduced to five days, at a total cost of $20,300 (this includes casting tooling costs). For Sylatech, the payback period for an Ultimaker 3D printer was less than three months.

Want to learn more about the savings you can achieve with 3D printing? Download the Ultimaker white paper for a deep dive into the topic.

Leave A Comment